Page 39: of Marine News Magazine (February 2016)

Dredging & Marine Construction

Read this page in Pdf, Flash or Html5 edition of February 2016 Marine News Magazine

DREDGING

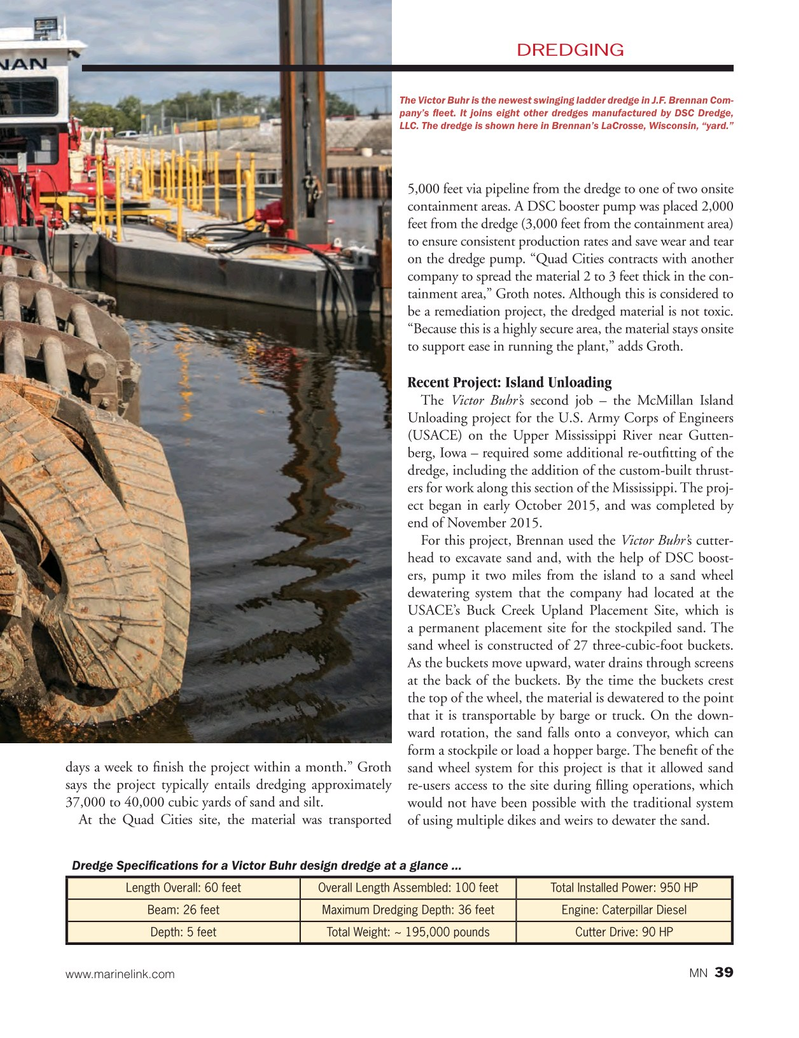

The Victor Buhr is the newest swinging ladder dredge in J.F. Brennan Com- pany’s ? eet. It joins eight other dredges manufactured by DSC Dredge,

LLC. The dredge is shown here in Brennan’s LaCrosse, Wisconsin, “yard.” 5,000 feet via pipeline from the dredge to one of two onsite containment areas. A DSC booster pump was placed 2,000 feet from the dredge (3,000 feet from the containment area) to ensure consistent production rates and save wear and tear on the dredge pump. “Quad Cities contracts with another company to spread the material 2 to 3 feet thick in the con- tainment area,” Groth notes. Although this is considered to be a remediation project, the dredged material is not toxic. “Because this is a highly secure area, the material stays onsite to support ease in running the plant,” adds Groth.

Recent Project: Island Unloading

The Victor Buhr’s second job – the McMillan Island

Unloading project for the U.S. Army Corps of Engineers (USACE) on the Upper Mississippi River near Gutten- berg, Iowa – required some additional re-out? tting of the dredge, including the addition of the custom-built thrust- ers for work along this section of the Mississippi. The proj- ect began in early October 2015, and was completed by end of November 2015.

For this project, Brennan used the Victor Buhr’s cutter- head to excavate sand and, with the help of DSC boost- ers, pump it two miles from the island to a sand wheel dewatering system that the company had located at the

USACE’s Buck Creek Upland Placement Site, which is a permanent placement site for the stockpiled sand. The sand wheel is constructed of 27 three-cubic-foot buckets.

As the buckets move upward, water drains through screens at the back of the buckets. By the time the buckets crest the top of the wheel, the material is dewatered to the point that it is transportable by barge or truck. On the down- ward rotation, the sand falls onto a conveyor, which can form a stockpile or load a hopper barge. The bene? t of the days a week to ? nish the project within a month.” Groth sand wheel system for this project is that it allowed sand says the project typically entails dredging approximately re-users access to the site during ? lling operations, which 37,000 to 40,000 cubic yards of sand and silt. would not have been possible with the traditional system

At the Quad Cities site, the material was transported of using multiple dikes and weirs to dewater the sand.

Dredge Speci? cations for a Victor Buhr design dredge at a glance ...

Length Overall: 60 feet Overall Length Assembled: 100 feetTotal Installed Power: 950 HP

Beam: 26 feet Maximum Dredging Depth: 36 feet Engine: Caterpillar Diesel

Depth: 5 feet Total Weight: ~ 195,000 pounds Cutter Drive: 90 HP 39 www.marinelink.com MN

MN Feb16 Layout 32-49.indd 39 1/21/2016 11:37:52 AM

38

38

40

40