Page 22: of Marine News Magazine (October 2016)

Salvage & Spill Response

Read this page in Pdf, Flash or Html5 edition of October 2016 Marine News Magazine

SPILL RESPONSE

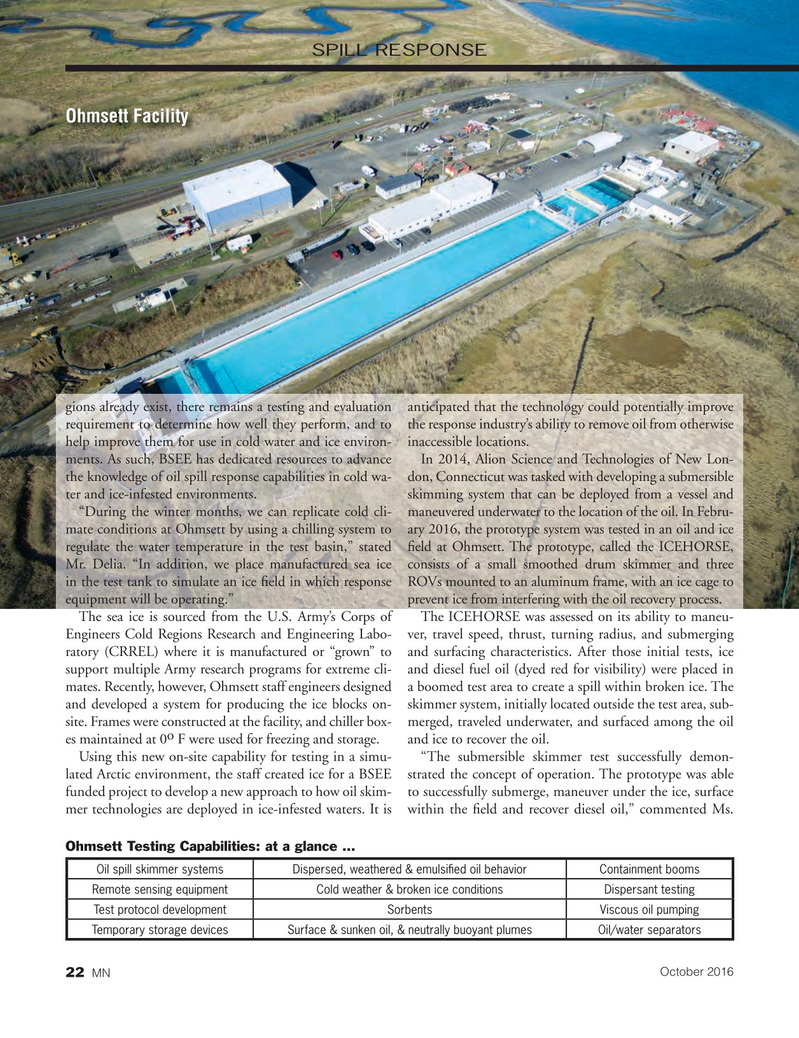

Ohmsett Facility gions already exist, there remains a testing and evaluation anticipated that the technology could potentially improve requirement to determine how well they perform, and to the response industry’s ability to remove oil from otherwise help improve them for use in cold water and ice environ- inaccessible locations. ments. As such, BSEE has dedicated resources to advance In 2014, Alion Science and Technologies of New Lon- the knowledge of oil spill response capabilities in cold wa- don, Connecticut was tasked with developing a submersible ter and ice-infested environments. skimming system that can be deployed from a vessel and “During the winter months, we can replicate cold cli- maneuvered underwater to the location of the oil. In Febru- mate conditions at Ohmsett by using a chilling system to ary 2016, the prototype system was tested in an oil and ice regulate the water temperature in the test basin,” stated ? eld at Ohmsett. The prototype, called the ICEHORSE,

Mr. Delia. “In addition, we place manufactured sea ice consists of a small smoothed drum skimmer and three in the test tank to simulate an ice ? eld in which response ROVs mounted to an aluminum frame, with an ice cage to equipment will be operating.” prevent ice from interfering with the oil recovery process.

The sea ice is sourced from the U.S. Army’s Corps of The ICEHORSE was assessed on its ability to maneu-

Engineers Cold Regions Research and Engineering Labo- ver, travel speed, thrust, turning radius, and submerging ratory (CRREL) where it is manufactured or “grown” to and surfacing characteristics. After those initial tests, ice support multiple Army research programs for extreme cli- and diesel fuel oil (dyed red for visibility) were placed in mates. Recently, however, Ohmsett staff engineers designed a boomed test area to create a spill within broken ice. The and developed a system for producing the ice blocks on- skimmer system, initially located outside the test area, sub- site. Frames were constructed at the facility, and chiller box- merged, traveled underwater, and surfaced among the oil es maintained at 0 o F were used for freezing and storage. and ice to recover the oil.

Using this new on-site capability for testing in a simu- “The submersible skimmer test successfully demon- lated Arctic environment, the staff created ice for a BSEE strated the concept of operation. The prototype was able funded project to develop a new approach to how oil skim- to successfully submerge, maneuver under the ice, surface mer technologies are deployed in ice-infested waters. It is within the ? eld and recover diesel oil,” commented Ms.

Ohmsett Testing Capabilities: at a glance …

Oil spill skimmer systems Dispersed, weathered & emulsi? ed oil behavior Containment booms

Remote sensing equipment Cold weather & broken ice conditions Dispersant testing

Test protocol development Sorbents Viscous oil pumping

Temporary storage devicesSurface & sunken oil, & neutrally buoyant plumes Oil/water separators

October 2016

MN 22

MN Oct16 Layout 18-31.indd 22 9/22/2016 10:06:34 AM

21

21

23

23