Page 28: of Marine News Magazine (June 2017)

Combat & Patrol Craft Annual

Read this page in Pdf, Flash or Html5 edition of June 2017 Marine News Magazine

LUBRICANTS

Not Aall EALs are Created Equal

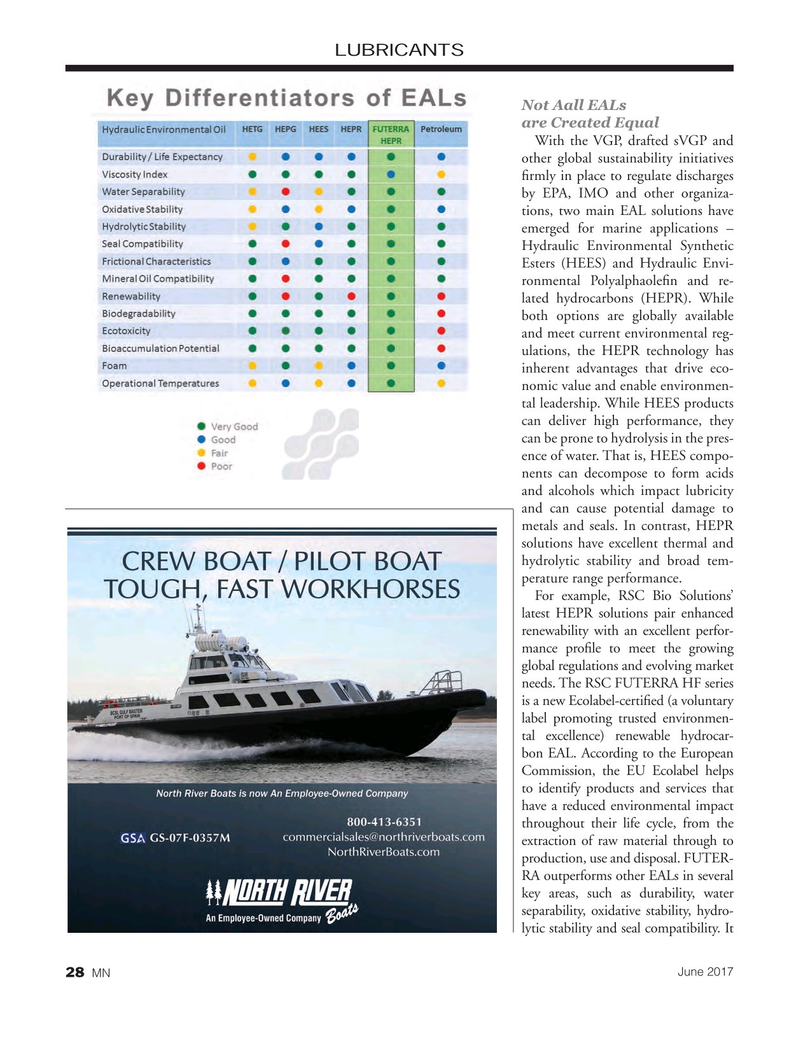

With the VGP, drafted sVGP and other global sustainability initiatives ? rmly in place to regulate discharges by EPA, IMO and other organiza- tions, two main EAL solutions have emerged for marine applications –

Hydraulic Environmental Synthetic

Esters (HEES) and Hydraulic Envi- ronmental Polyalphaole? n and re- lated hydrocarbons (HEPR). While both options are globally available and meet current environmental reg- ulations, the HEPR technology has inherent advantages that drive eco- nomic value and enable environmen- tal leadership. While HEES products can deliver high performance, they can be prone to hydrolysis in the pres- ence of water. That is, HEES compo- nents can decompose to form acids and alcohols which impact lubricity and can cause potential damage to metals and seals. In contrast, HEPR solutions have excellent thermal and hydrolytic stability and broad tem- perature range performance.

For example, RSC Bio Solutions’ latest HEPR solutions pair enhanced renewability with an excellent perfor- mance pro? le to meet the growing global regulations and evolving market needs. The RSC FUTERRA HF series is a new Ecolabel-certi? ed (a voluntary label promoting trusted environmen- tal excellence) renewable hydrocar- bon EAL. According to the European

Commission, the EU Ecolabel helps to identify products and services that have a reduced environmental impact throughout their life cycle, from the extraction of raw material through to production, use and disposal. FUTER-

RA outperforms other EALs in several key areas, such as durability, water separability, oxidative stability, hydro- lytic stability and seal compatibility. It

June 2017

MN 28

27

27

29

29