Page 80: of Marine News Magazine (November 2017)

Workboat Annual

Read this page in Pdf, Flash or Html5 edition of November 2017 Marine News Magazine

WORKBOAT HARDWARE

IN USE TODAY a week earlier was a ‘win-win’ for everyone concerned.

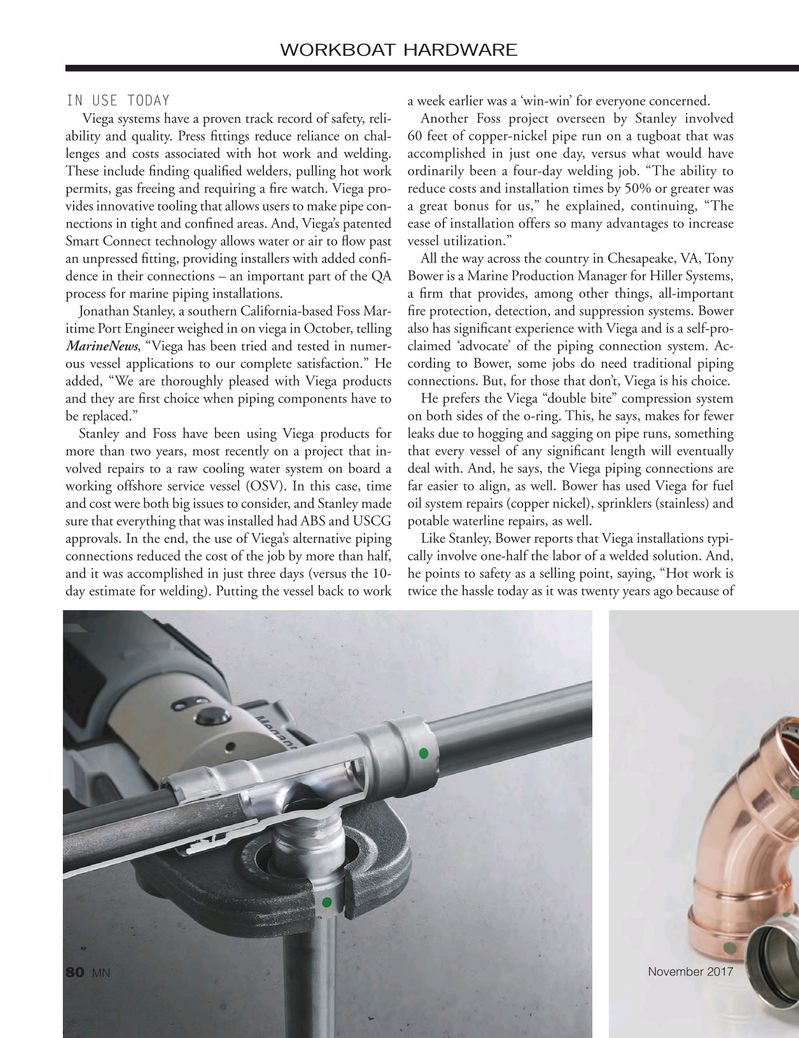

Viega systems have a proven track record of safety, reli- Another Foss project overseen by Stanley involved ability and quality. Press ? ttings reduce reliance on chal- 60 feet of copper-nickel pipe run on a tugboat that was lenges and costs associated with hot work and welding. accomplished in just one day, versus what would have

These include ? nding quali? ed welders, pulling hot work ordinarily been a four-day welding job. “The ability to permits, gas freeing and requiring a ? re watch. Viega pro- reduce costs and installation times by 50% or greater was vides innovative tooling that allows users to make pipe con- a great bonus for us,” he explained, continuing, “The nections in tight and con? ned areas. And, Viega’s patented ease of installation offers so many advantages to increase

Smart Connect technology allows water or air to ? ow past vessel utilization.” an unpressed ? tting, providing installers with added con? - All the way across the country in Chesapeake, VA, Tony dence in their connections – an important part of the QA Bower is a Marine Production Manager for Hiller Systems, process for marine piping installations. a ? rm that provides, among other things, all-important

Jonathan Stanley, a southern California-based Foss Mar- ? re protection, detection, and suppression systems. Bower itime Port Engineer weighed in on viega in October, telling also has signi? cant experience with Viega and is a self-pro-

MarineNews, “Viega has been tried and tested in numer- claimed ‘advocate’ of the piping connection system. Ac- ous vessel applications to our complete satisfaction.” He cording to Bower, some jobs do need traditional piping added, “We are thoroughly pleased with Viega products connections. But, for those that don’t, Viega is his choice.

and they are ? rst choice when piping components have to He prefers the Viega “double bite” compression system be replaced.” on both sides of the o-ring. This, he says, makes for fewer

Stanley and Foss have been using Viega products for leaks due to hogging and sagging on pipe runs, something more than two years, most recently on a project that in- that every vessel of any signi? cant length will eventually volved repairs to a raw cooling water system on board a deal with. And, he says, the Viega piping connections are working offshore service vessel (OSV). In this case, time far easier to align, as well. Bower has used Viega for fuel and cost were both big issues to consider, and Stanley made oil system repairs (copper nickel), sprinklers (stainless) and sure that everything that was installed had ABS and USCG potable waterline repairs, as well.

approvals. In the end, the use of Viega’s alternative piping Like Stanley, Bower reports that Viega installations typi- connections reduced the cost of the job by more than half, cally involve one-half the labor of a welded solution. And, and it was accomplished in just three days (versus the 10- he points to safety as a selling point, saying, “Hot work is day estimate for welding). Putting the vessel back to work twice the hassle today as it was twenty years ago because of

November 2017

MN 80

79

79

81

81