Page 50: of Marine News Magazine (February 2018)

Dredging & Marine Construction

Read this page in Pdf, Flash or Html5 edition of February 2018 Marine News Magazine

VESSELS

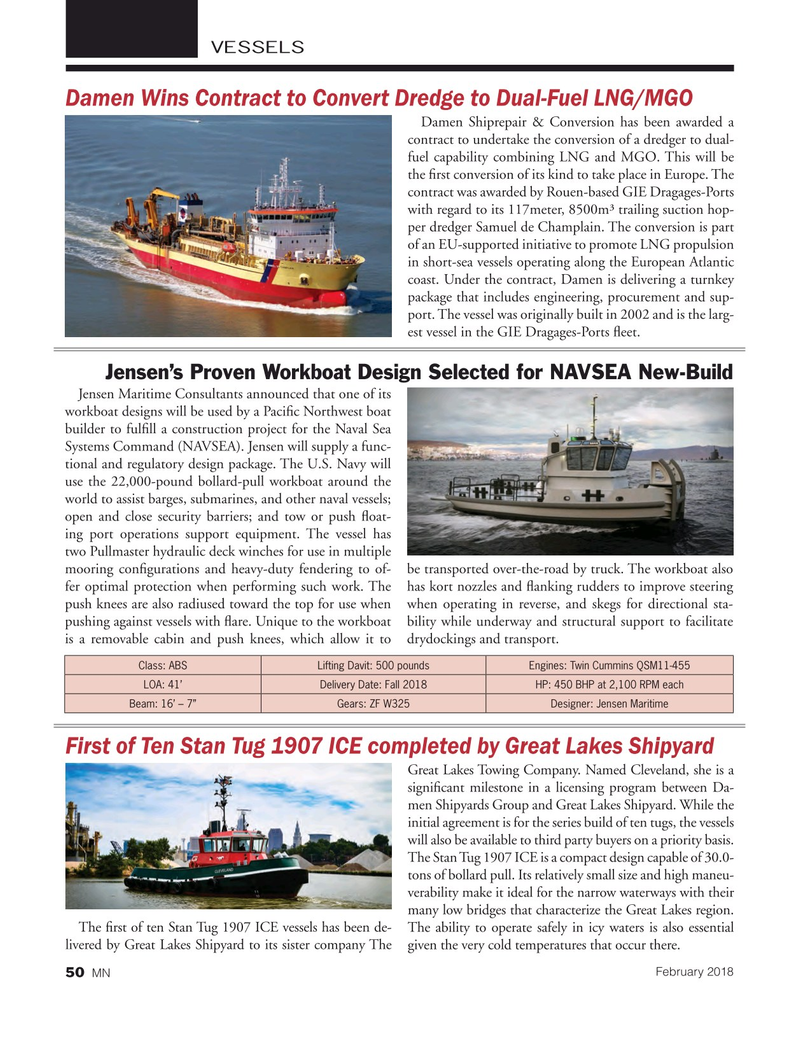

Damen Wins Contract to Convert Dredge to Dual-Fuel LNG/MGO

Damen Shiprepair & Conversion has been awarded a contract to undertake the conversion of a dredger to dual- fuel capability combining LNG and MGO. This will be the ? rst conversion of its kind to take place in Europe. The contract was awarded by Rouen-based GIE Dragages-Ports with regard to its 117meter, 8500m³ trailing suction hop- per dredger Samuel de Champlain. The conversion is part of an EU-supported initiative to promote LNG propulsion in short-sea vessels operating along the European Atlantic coast. Under the contract, Damen is delivering a turnkey package that includes engineering, procurement and sup- port. The vessel was originally built in 2002 and is the larg- est vessel in the GIE Dragages-Ports ? eet.

Jensen’s Proven Workboat Design Selected for NAVSEA New-Build

Jensen Maritime Consultants announced that one of its workboat designs will be used by a Paci? c Northwest boat builder to ful? ll a construction project for the Naval Sea

Systems Command (NAVSEA). Jensen will supply a func- tional and regulatory design package. The U.S. Navy will use the 22,000-pound bollard-pull workboat around the world to assist barges, submarines, and other naval vessels; open and close security barriers; and tow or push ? oat- ing port operations support equipment. The vessel has two Pullmaster hydraulic deck winches for use in multiple mooring con? gurations and heavy-duty fendering to of- be transported over-the-road by truck. The workboat also fer optimal protection when performing such work. The has kort nozzles and ? anking rudders to improve steering push knees are also radiused toward the top for use when when operating in reverse, and skegs for directional sta- pushing against vessels with ? are. Unique to the workboat bility while underway and structural support to facilitate is a removable cabin and push knees, which allow it to drydockings and transport.

Class: ABS Lifting Davit: 500 pounds Engines: Twin Cummins QSM11-455

LOA: 41’ Delivery Date: Fall 2018 HP: 450 BHP at 2,100 RPM each

Beam: 16’ – 7” Gears: ZF W325 Designer: Jensen Maritime

First of Ten Stan Tug 1907 ICE completed by Great Lakes Shipyard

Great Lakes Towing Company. Named Cleveland, she is a signi? cant milestone in a licensing program between Da- men Shipyards Group and Great Lakes Shipyard. While the initial agreement is for the series build of ten tugs, the vessels will also be available to third party buyers on a priority basis.

The Stan Tug 1907 ICE is a compact design capable of 30.0- tons of bollard pull. Its relatively small size and high maneu- verability make it ideal for the narrow waterways with their many low bridges that characterize the Great Lakes region.

The ? rst of ten Stan Tug 1907 ICE vessels has been de- The ability to operate safely in icy waters is also essential livered by Great Lakes Shipyard to its sister company The given the very cold temperatures that occur there.

February 2018

MN 50

49

49

51

51