Page 49: of Marine News Magazine (April 2018)

Boatbuilding, Construction & Repair

Read this page in Pdf, Flash or Html5 edition of April 2018 Marine News Magazine

COATINGS erwise, we would have ended up with more color drift, ule. Doing so allowed the shipyard to coat the engine room which we had just solved,” said Starck. before installing equipment, which meant applicators faced limited obstacles and were able to ensure complete coverage.

Covering Every Square Inch “Sherwin-Williams matched the engine color and sheen

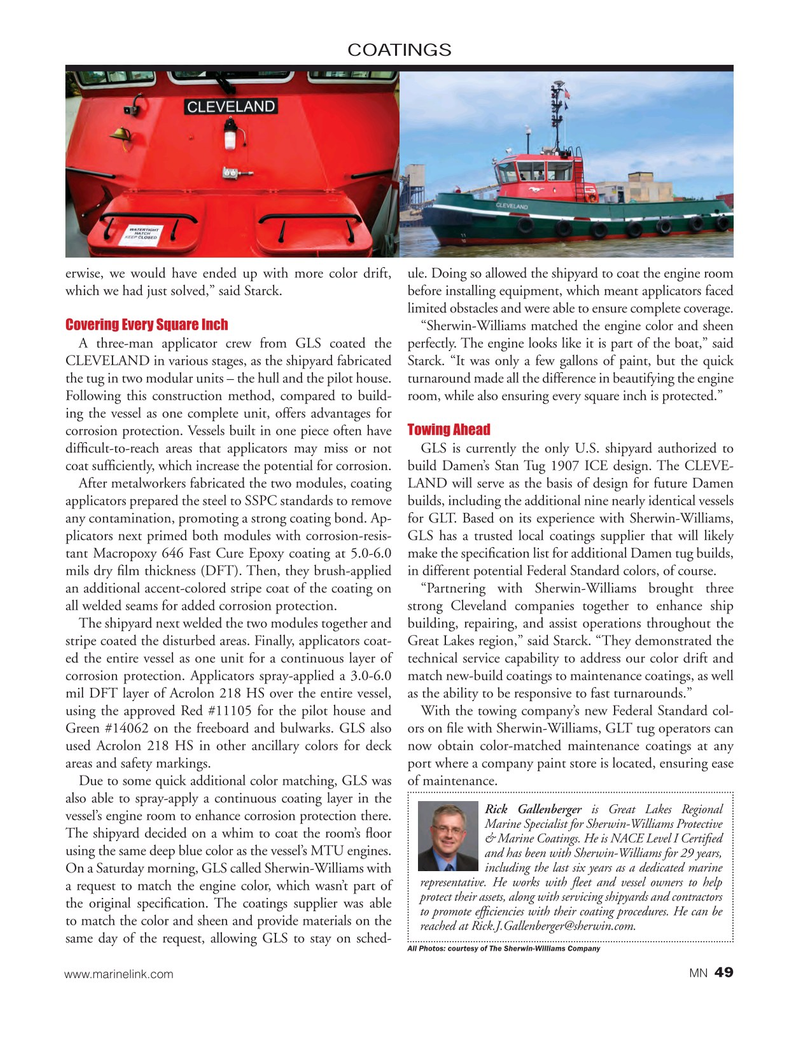

A three-man applicator crew from GLS coated the perfectly. The engine looks like it is part of the boat,” said

CLEVELAND in various stages, as the shipyard fabricated Starck. “It was only a few gallons of paint, but the quick the tug in two modular units – the hull and the pilot house. turnaround made all the difference in beautifying the engine

Following this construction method, compared to build- room, while also ensuring every square inch is protected.” ing the vessel as one complete unit, offers advantages for corrosion protection. Vessels built in one piece often have Towing Ahead dif

48

48

50

50