Page 28: of Marine News Magazine (July 2018)

Propulsion Technology

Read this page in Pdf, Flash or Html5 edition of July 2018 Marine News Magazine

COLUMN LUBRICANTS ever, a brief de? nition is: An EAL is a lubricant that meets de- • Closed Systems on deck could include sealed bearings, cyl- ? ned standards for toxicity, bioaccumulation and biodegradability. inder oils, compressors, heat transfer ? uids and enclosed gear-

Products on the market that promote achieving some boxes or chain drives. For these applications, the traditional environmental advantage compared to traditional mineral lubricant can and likely should continue to be employed. oil based products, but do not meet the EPA standards, • Open Systems are where the lubricant is lost in use. These are of limited environmental bene? t and will not satisfy would include winch girth and pinion gears, re-lubricated the requirements of the Vessel General Permit. A statement bearings, pins, bushings and sheaves on davits, wires or cable, from the lubricant supplier on the product data sheet or in level winders on wire drums, chains on open drive systems, doors a separate letter of certi? cation should be included in the and hatches, guide rails, slewing gears on cranes and stern rollers vessel documentation to ensure you are using a product and fairleads. These systems should be the ? rst to be converted that meets the criteria. because the lubricant can easily ? nd its way into the environ-

Which applications to convert to EALs can be deter- ment through rain, waves and deck washes. mined by taking an inventory of applications on deck that • At-Risk Systems would include hydraulic cranes, winches require lubrication and separating them into three catego- and hatch covers and enclosed gearboxes where a leaking sys- ries: closed systems, open systems and at-risk systems: tem or blown hose cannot be contained effectively. For these

Choosing a Specialty lubricant … at a glance:

Cost: What is the total cost for the system not just the price of the product? Will overall costs be reduced through reduced consumption, extended lubrication intervals or improved protection of the equipment?

Compatibility: Lubricants work in combination with metals, hoses, seals, previous lubricants used and possible future lubricants and paints. Does the lubricant work with each of these other components?

Chemistry: A basic understanding of different base oils, thickeners, additives and modi? ers can be invaluable in narrowing down the list of potential products available.

Conditions: What are the conditions the lubricant will be exposed to, such as: temperature, speed, pressure, size of mechanical element, frequency of use and past failures?

Performance: What are the stated and/or expected results from the lubricant? What test data, trials or experience support the product claims?

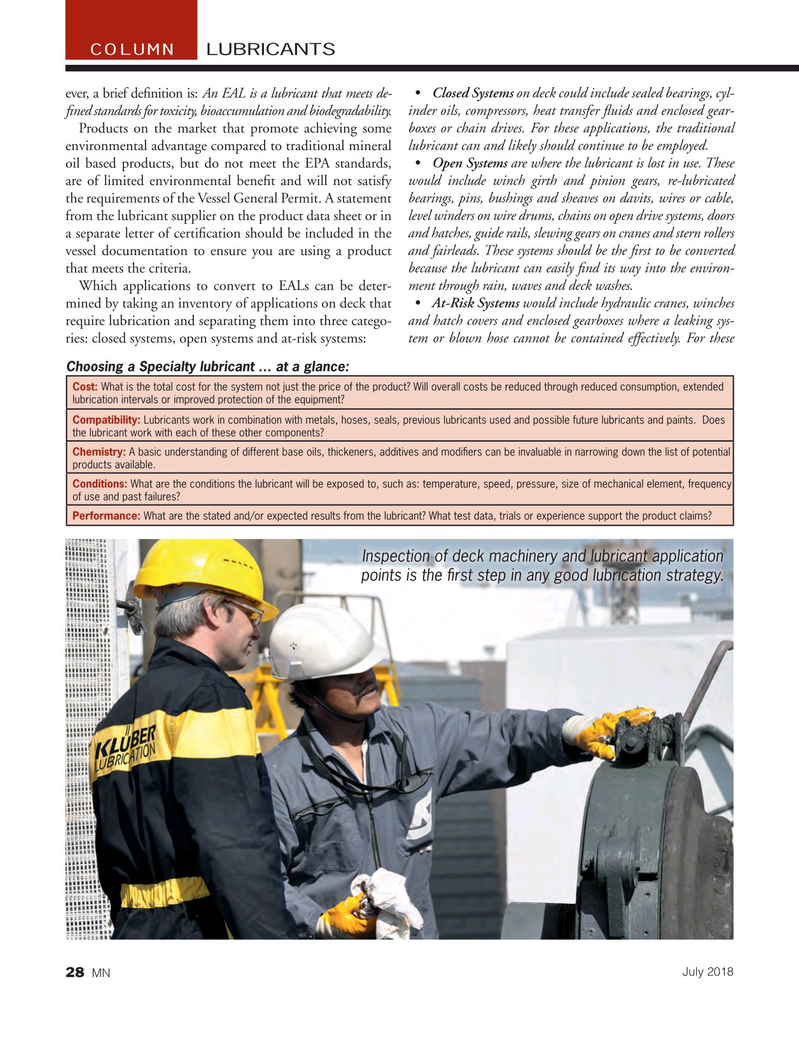

Inspection of deck machinery and lubricant application points is the ? rst step in any good lubrication strategy.

July 2018

MN 28

MN July18 Layout 18-31.indd 28 MN July18 Layout 18-31.indd 28 6/19/2018 4:14:58 PM6/19/2018 4:14:58 PM

27

27

29

29