Page 42: of Marine News Magazine (April 2019)

Boatbuilding, Construction & Repair

Read this page in Pdf, Flash or Html5 edition of April 2019 Marine News Magazine

COATINGS/CORROSION CONTROL “Being able to do the work in a controlled environment that is weather proof means more than just cost-savings for us. It allows us to deliver work of enhanced quality to our customers, which is really why this in- vestment is so critical to us. For example, we no longer experience f ash rusting from a sudden rain shower or from high humidity, and the paint is applied under proper humidity conditions, day and night. In the past, the dif erence in humidity and temperature levels had prevented us from doing paint work at night, but with this facility, we now can.” – Timothy Pryor, PE, VT Halter Marine Facilities and Structural Engineer ? ash rust and not delaying painting times while waiting for better using less paint, with less chances of re-work due to the humidity to improve is a huge time advantage. weather or environmental related factors. This results in

With 65 blasters and painters working on a two-shift better schedule conformance and lower man-hours.” basis, the yard is certainly getting its money’s worth out of the new shop. But, that’s only half the story. VT Halter Environmentally Friendly: two kinds of green

CEO Baczkowski reports manning and labor curves that Even as ef? ciency improvements drive the bottom line produce close to 40 percent ef? ciencies as a function of for most shipyards, for VT Halter, one of the most im- using the facility. We asked Pryor to substantiate those portant reasons to building this state-of-the art facility claims. “When you stop losing 30% of your paint to the involved the protection of the environment and the sur- wind you are naturally using less man-hours. When you rounding communities. As the facility collects that blast stop re-blasting because it rained, you reduce that re-work material as it is used, it is also ? ltered and eventually re- time by 100%. It becomes very easy to do better.” cycled. Actually, the planned safeguards go much deeper.

When we suggested that 40% ef? ciency improvements The air that is supplied to the workers is ? ltered and in paint and coatings for a large hull would translate into heated or cooled as required, promoting better productivi- a competitive advantage, Pryor agreed but insisted that the ty as the environment becomes more comfortable. Beyond real advantage – at least in the eyes of the customer – rests the air supply to the blast hall and paint booths, all work- elsewhere. “The customers that I have talked to certainly ers are supplied with 4-stage ? ltered breathing air to their can see the natural advantage of lower costs, but what in- hoods that is monitored for carbon monoxide and which terests them most is the increase in quality from painting come with visual and audible alarms. This air supply can on a cleanly blasted unit. The facility enables us to paint also be used to provide cooling under their hoods.

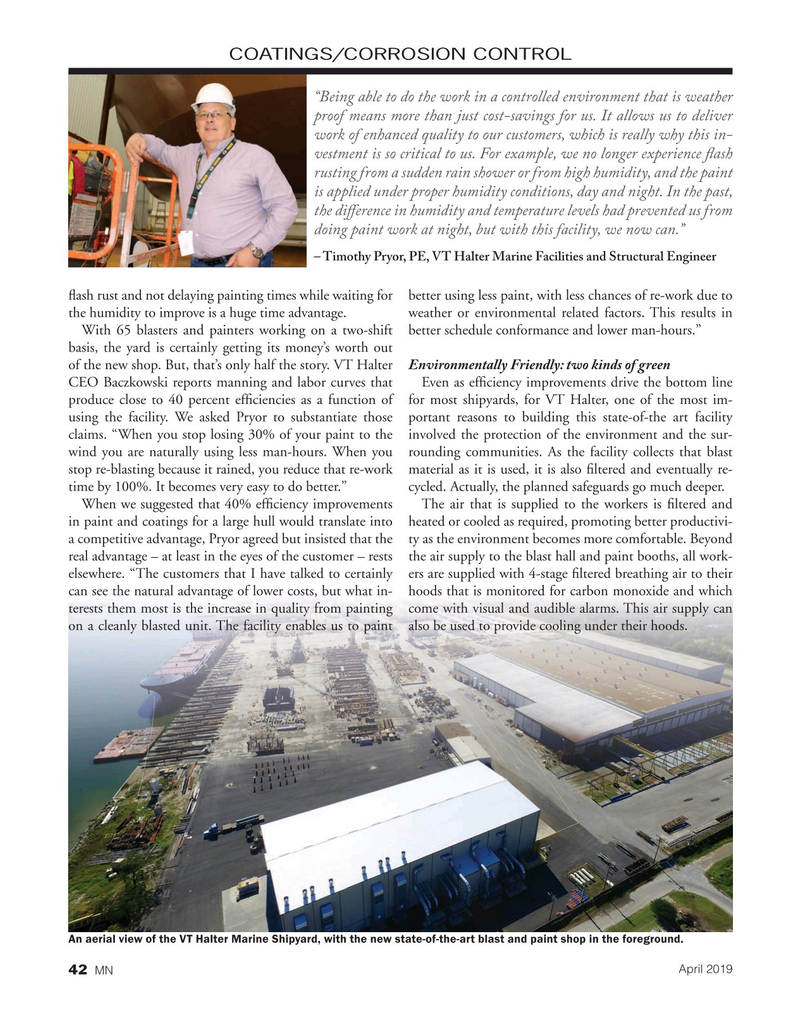

An aerial view of the VT Halter Marine Shipyard, with the new state-of-the-art blast and paint shop in the foreground.

April 2019 42 MN

41

41

43

43