Page 50: of Marine News Magazine (May 2019)

Inland Waterways

Read this page in Pdf, Flash or Html5 edition of May 2019 Marine News Magazine

ech file

T leaving the usual puddles of fuel trapped by the numerous con? ned tank space. This also results in a more environ- internal structures within the tank. The wing tank on one mentally friendly solution, as no additional hazardous side was then degassed using NanoVapor, while the tank waste is created in this gas freeing process.

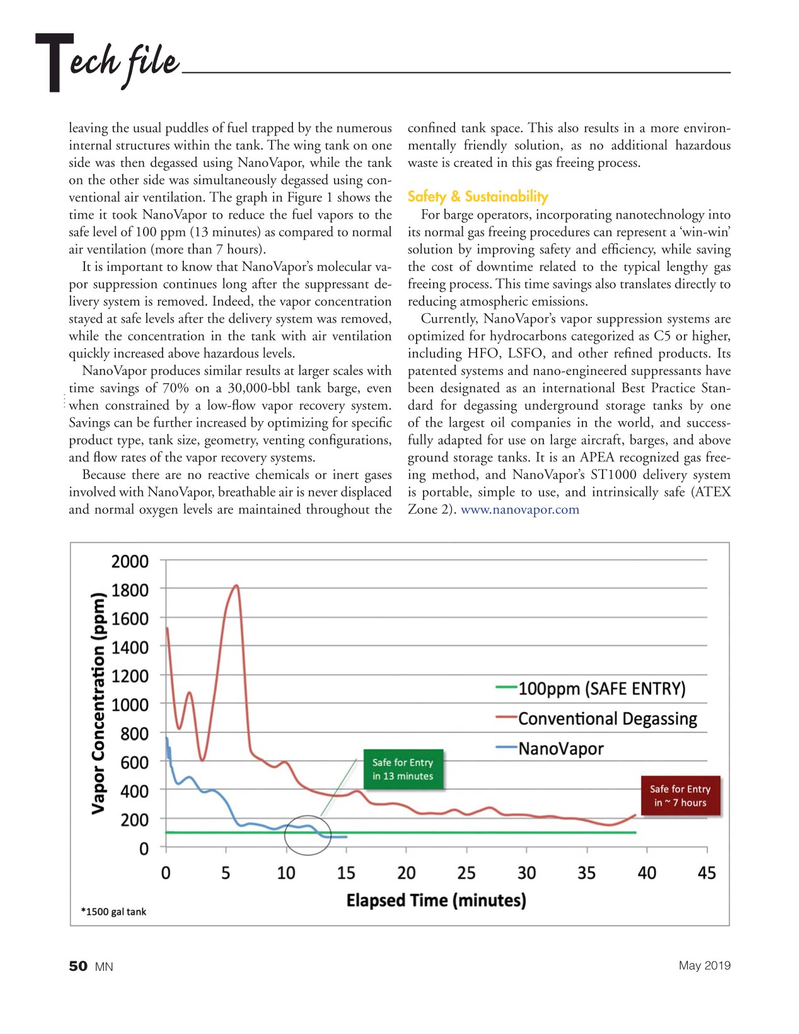

on the other side was simultaneously degassed using con- ventional air ventilation. The graph in Figure 1 shows the Safety & Sustainability time it took NanoVapor to reduce the fuel vapors to the For barge operators, incorporating nanotechnology into safe level of 100 ppm (13 minutes) as compared to normal its normal gas freeing procedures can represent a ‘win-win’ air ventilation (more than 7 hours). solution by improving safety and ef? ciency, while saving

It is important to know that NanoVapor’s molecular va- the cost of downtime related to the typical lengthy gas por suppression continues long after the suppressant de- freeing process. This time savings also translates directly to livery system is removed. Indeed, the vapor concentration reducing atmospheric emissions.

stayed at safe levels after the delivery system was removed, Currently, NanoVapor’s vapor suppression systems are while the concentration in the tank with air ventilation optimized for hydrocarbons categorized as C5 or higher, quickly increased above hazardous levels. including HFO, LSFO, and other re? ned products. Its

NanoVapor produces similar results at larger scales with patented systems and nano-engineered suppressants have time savings of 70% on a 30,000-bbl tank barge, even been designated as an international Best Practice Stan- when constrained by a low-? ow vapor recovery system. dard for degassing underground storage tanks by one

Savings can be further increased by optimizing for speci? c of the largest oil companies in the world, and success- product type, tank size, geometry, venting con? gurations, fully adapted for use on large aircraft, barges, and above and ? ow rates of the vapor recovery systems. ground storage tanks. It is an APEA recognized gas free-

Because there are no reactive chemicals or inert gases ing method, and NanoVapor’s ST1000 delivery system involved with NanoVapor, breathable air is never displaced is portable, simple to use, and intrinsically safe (ATEX and normal oxygen levels are maintained throughout the Zone 2). www.nanovapor.com

May 2019 50

MN

49

49

51

51