Page 42: of Marine News Magazine (March 2020)

Workboat Conversion & Repair

Read this page in Pdf, Flash or Html5 edition of March 2020 Marine News Magazine

REPAIR & CONVERSION 1,000-foot freighters. 100-year-old tugs

American ? ag vessels have been ordered to operate since Such long and unwieldy lakers on the often-narrow

January 1, 2015, in compliance within the North Ameri- pathways of the Great Lakes waterways demand a ? eet of can Emissions Control Area (essentially all U.S. and Ca- skilled tugs. nadian fresh and saltwater coasts). The sulfur content of Marine News spoke to Kirsten Buccigrossi, Director, vessel fuel must be no more than 0.1% by weight, a sub- Marketing & Communications for The Great Lakes Tow- stantial reduction from the 1% allowed in 2010. So, this ing Company and Great Lakes Shipyard. Great Lakes Tow- is a pressing need. ing’s ? eet of tugs is the largest on the Great Lakes.

“We can install closed-loop, open-loop and hybrid sys- “Many of our tugs are around a hundred years old,” she tems. We transform ships to make them scrubber-ready by said with remarkable calm. “We change out the engines at providing extensive structural, piping and electrical modi- about every 40 years. The last one was back in the ’70s.” ? cations and can minimize downtime by accomplishing “It is pretty wild,” Buccigrossi said. “But operating in this during the winter layup,” Koch said. fresh water, we have no issue with salt corrosion on the “FBS has also completed 14 engine repowerings which steel. And they are all good U.S. steel.” are more energy and emission ef? cient, ranging from She said federal regulations ? nally made it cheaper to 1,000-foot vessels to passenger ferries and tugs. Both of build new tugs and retire the 100-year-olds. “We are build- these services have been trends over the last several years,” ing about one new tug a year at our Great Lakes Shipyard.”

Koch said. “For the last 10 years, we’ve also provided elec- Last winter, the company’s shipyard worked the Ameri- trical retro? ts of original deck winches to new, user-friend- can Steamship Company’s 635-foot Sam Laud, but hosted ly operations.” no lakers this year, Buccigrossi said.

“Installing waste heat boilers has been a common part “For winter work on lakers, typical service/mainte- of conversions we’ve done. We have also gained experience nance includes routine inspections, steel reinforcement, in installing and operating various ballast water treatment etc. In addition, we provide a wide variety of services systems,” Koch said. on other vessels that are not lakers (i.e., research vessels, ferries, ? reboats, tugs, barges, etc). These services in-

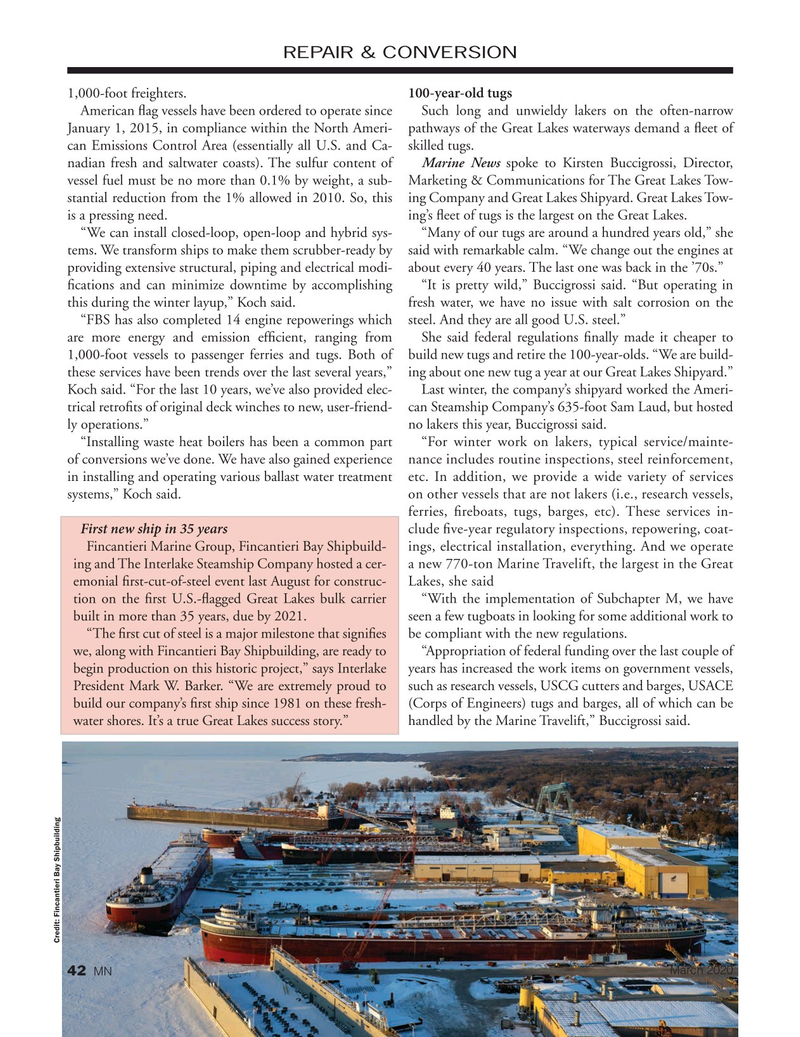

First new ship in 35 years clude ? ve-year regulatory inspections, repowering, coat-

Fincantieri Marine Group, Fincantieri Bay Shipbuild- ings, electrical installation, everything. And we operate ing and The Interlake Steamship Company hosted a cer- a new 770-ton Marine Travelift, the largest in the Great emonial ? rst-cut-of-steel event last August for construc- Lakes, she said tion on the ? rst U.S.-? agged Great Lakes bulk carrier “With the implementation of Subchapter M, we have built in more than 35 years, due by 2021. seen a few tugboats in looking for some additional work to “The ? rst cut of steel is a major milestone that signi? es be compliant with the new regulations.

we, along with Fincantieri Bay Shipbuilding, are ready to “Appropriation of federal funding over the last couple of begin production on this historic project,” says Interlake years has increased the work items on government vessels,

President Mark W. Barker. “We are extremely proud to such as research vessels, USCG cutters and barges, USACE build our company’s ? rst ship since 1981 on these fresh- (Corps of Engineers) tugs and barges, all of which can be water shores. It’s a true Great Lakes success story.” handled by the Marine Travelift,” Buccigrossi said.

Credit: Fincantieri Bay Shipbuilding

March 2020 42 MN

41

41

43

43