Page 45: of Marine News Magazine (March 2020)

Workboat Conversion & Repair

Read this page in Pdf, Flash or Html5 edition of March 2020 Marine News Magazine

LUBRICANTS

COMPOSITION OF LUBRICATING OILS AND GREASES phorous-based anti-wear additives that form a protective

A lubricating oil consists of a base oil, additives and – in layer on top of metal surfaces, sulphur-based extreme some cases – solid lubricants. A lubricating grease is cre- pressure additives that prevent spot welding under high ated by adding thickener to the oil. loads and corrosion inhibitors to reduce rust.

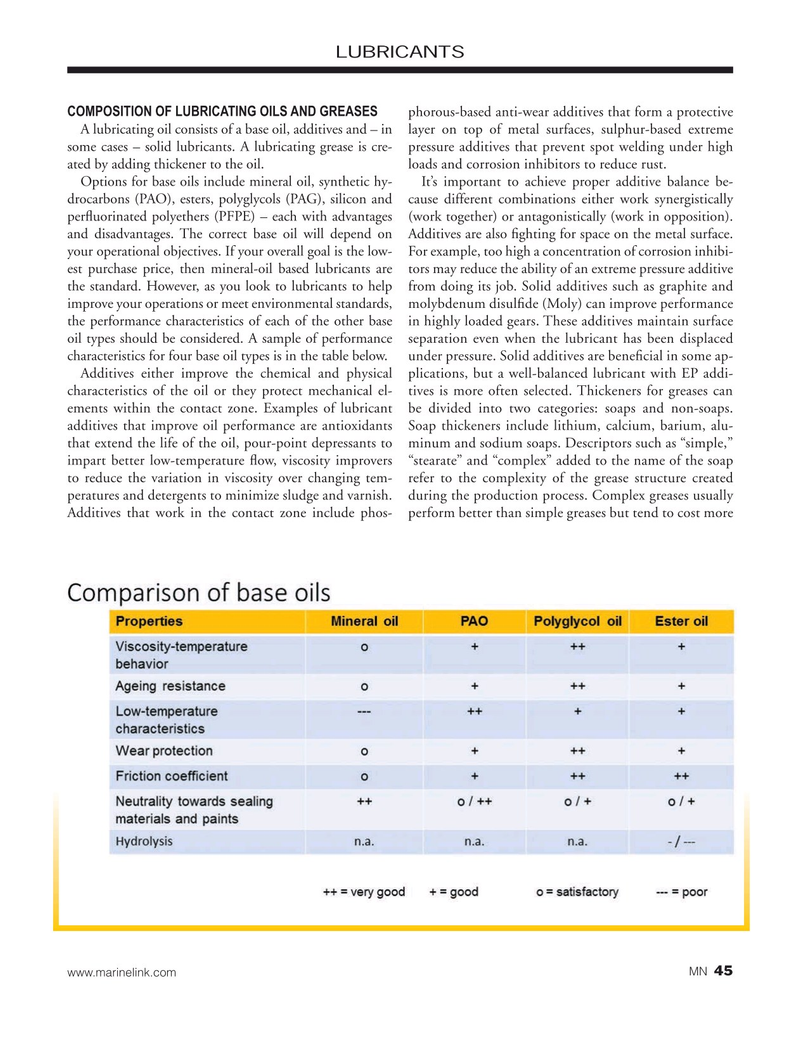

Options for base oils include mineral oil, synthetic hy- It’s important to achieve proper additive balance be- drocarbons (PAO), esters, polyglycols (PAG), silicon and cause different combinations either work synergistically per? uorinated polyethers (PFPE) – each with advantages (work together) or antagonistically (work in opposition). and disadvantages. The correct base oil will depend on Additives are also ? ghting for space on the metal surface. your operational objectives. If your overall goal is the low- For example, too high a concentration of corrosion inhibi- est purchase price, then mineral-oil based lubricants are tors may reduce the ability of an extreme pressure additive the standard. However, as you look to lubricants to help from doing its job. Solid additives such as graphite and improve your operations or meet environmental standards, molybdenum disul? de (Moly) can improve performance the performance characteristics of each of the other base in highly loaded gears. These additives maintain surface oil types should be considered. A sample of performance separation even when the lubricant has been displaced characteristics for four base oil types is in the table below. under pressure. Solid additives are bene? cial in some ap-

Additives either improve the chemical and physical plications, but a well-balanced lubricant with EP addi- characteristics of the oil or they protect mechanical el- tives is more often selected. Thickeners for greases can ements within the contact zone. Examples of lubricant be divided into two categories: soaps and non-soaps. additives that improve oil performance are antioxidants Soap thickeners include lithium, calcium, barium, alu- that extend the life of the oil, pour-point depressants to minum and sodium soaps. Descriptors such as “simple,” impart better low-temperature ? ow, viscosity improvers “stearate” and “complex” added to the name of the soap to reduce the variation in viscosity over changing tem- refer to the complexity of the grease structure created peratures and detergents to minimize sludge and varnish. during the production process. Complex greases usually

Additives that work in the contact zone include phos- perform better than simple greases but tend to cost more 45 www.marinelink.com MN

44

44

46

46