Page 13: of Marine News Magazine (April 2020)

Autonomous Workboats

Read this page in Pdf, Flash or Html5 edition of April 2020 Marine News Magazine

building, now known as Fincantieri Bay Shipbuilding. His ex- perience began as a light metal production boilermaker, where he advanced to become Foreman and the head of the light metal and insulating department. He then became Assistant

Manager and Manager of Commercial Ship Repair Services until 2001 when he was named Director of Ship Repair Ser- vices and Major Conversion. In 2012, he was named Vice

President and General Manager, the role he continues to serve in to this day.

Thayse received his initial training at Northeast Wisconsin

Technical Colleague in metals fabrication and layout. He is a state certi?ed trainer and former project manager in asbes- tos abatement. Todd received additional leadership training through the University of Kansas, UW-Madison Extension and Manitowoc Company.

Please give a by-the-numbers rundown of Fincantieri

Bay Shipbuilding today.

We are hovering right around 1,000 employees right now.

Some of that total is seasonal help brought on to complete the annual winter repair work. We have 12 repair vessels in the yard this year with four of those vessels having been cycled through the drydock for surveys.

What portion of your business is new build vs. repair?

Our yearly sales volume (repair vs. new construction) ?uc- tuates year over year depending on where we may be with new build deliveries, and of course, the cyclicality of the Great

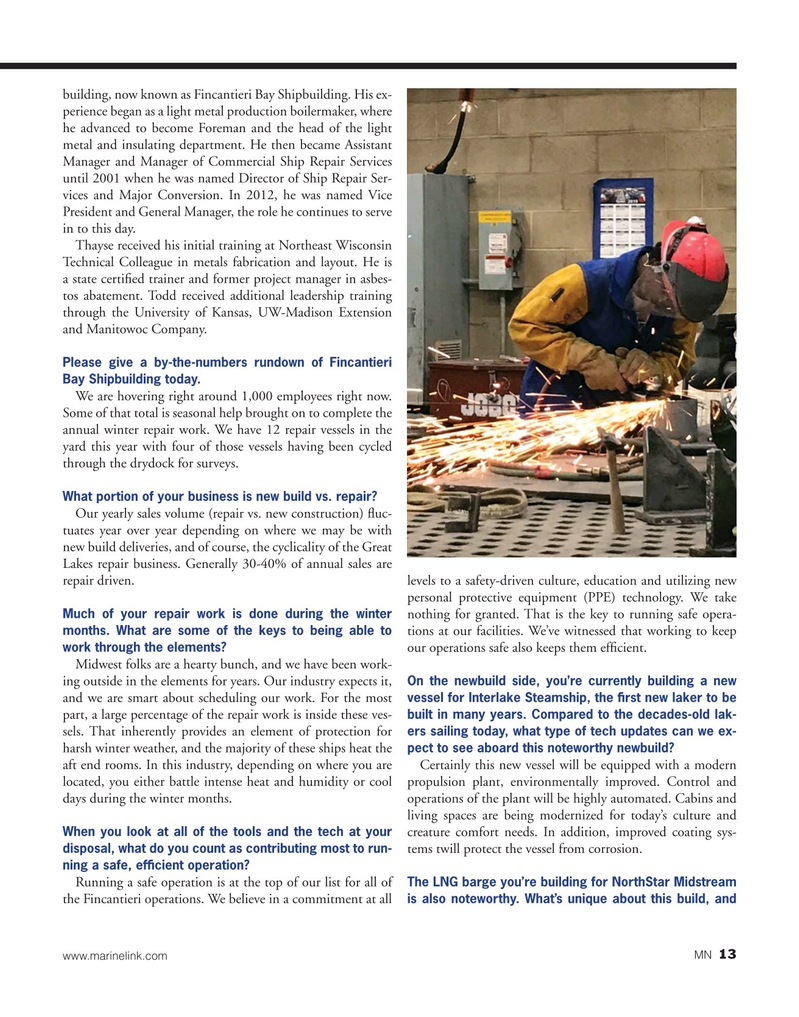

Lakes repair business. Generally 30-40% of annual sales are repair driven. levels to a safety-driven culture, education and utilizing new personal protective equipment (PPE) technology. We take

Much of your repair work is done during the winter nothing for granted. That is the key to running safe opera- months. What are some of the keys to being able to tions at our facilities. We’ve witnessed that working to keep work through the elements?

our operations safe also keeps them ef?cient.

Midwest folks are a hearty bunch, and we have been work- ing outside in the elements for years. Our industry expects it,

On the newbuild side, you’re currently building a new and we are smart about scheduling our work. For the most vessel for Interlake Steamship, the ?rst new laker to be part, a large percentage of the repair work is inside these ves- built in many years. Compared to the decades-old lak- sels. That inherently provides an element of protection for ers sailing today, what type of tech updates can we ex- harsh winter weather, and the majority of these ships heat the pect to see aboard this noteworthy newbuild?

aft end rooms. In this industry, depending on where you are Certainly this new vessel will be equipped with a modern located, you either battle intense heat and humidity or cool propulsion plant, environmentally improved. Control and days during the winter months. operations of the plant will be highly automated. Cabins and living spaces are being modernized for today’s culture and

When you look at all of the tools and the tech at your creature comfort needs. In addition, improved coating sys- disposal, what do you count as contributing most to run- tems twill protect the vessel from corrosion. ning a safe, ef?cient operation?

Running a safe operation is at the top of our list for all of

The LNG barge you’re building for NorthStar Midstream the Fincantieri operations. We believe in a commitment at all is also noteworthy. What’s unique about this build, and 13 www.marinelink.com MN

12

12

14

14