Page 58: of Marine News Magazine (May 2020)

Inland Waterways

Read this page in Pdf, Flash or Html5 edition of May 2020 Marine News Magazine

PRODUCTS

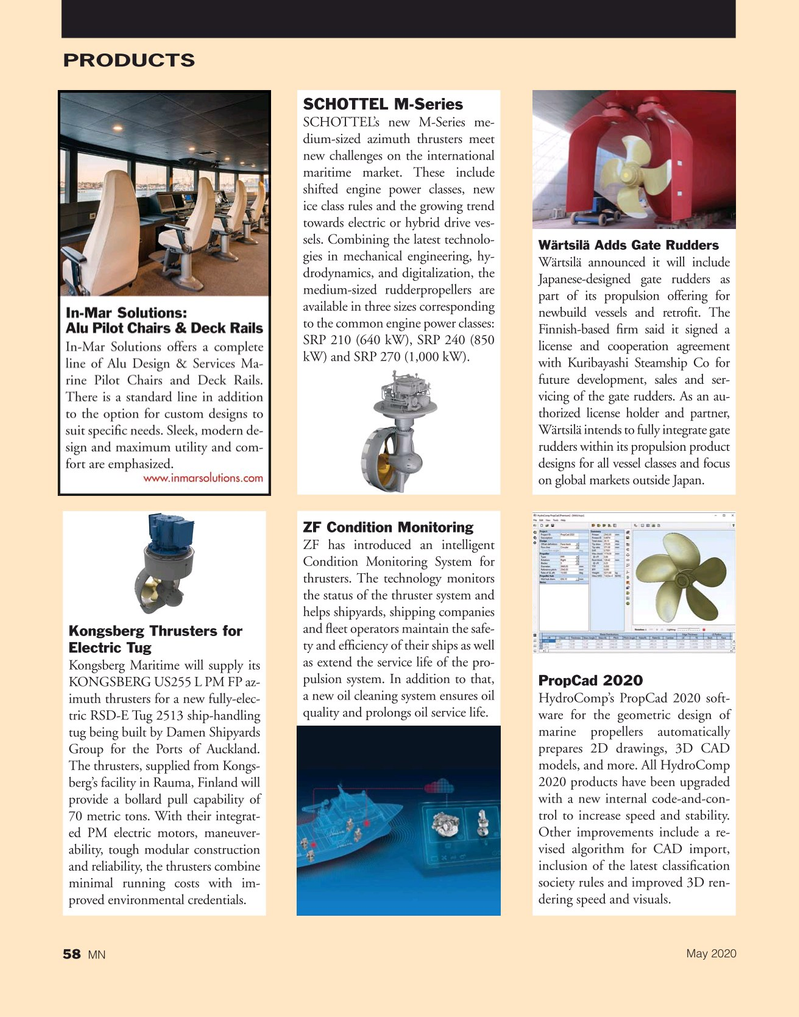

SCHOTTEL M-Series

SCHOTTEL’s new M-Series me- dium-sized azimuth thrusters meet new challenges on the international maritime market. These include shifted engine power classes, new ice class rules and the growing trend towards electric or hybrid drive ves- sels. Combining the latest technolo-

Wärtsilä Adds Gate Rudders gies in mechanical engineering, hy-

Wärtsilä announced it will include drodynamics, and digitalization, the

Japanese-designed gate rudders as medium-sized rudderpropellers are part of its propulsion offering for available in three sizes corresponding newbuild vessels and retro?t. The to the common engine power classes:

Finnish-based ?rm said it signed a

SRP 210 (640 kW), SRP 240 (850 license and cooperation agreement kW) and SRP 270 (1,000 kW).

with Kuribayashi Steamship Co for future development, sales and ser- vicing of the gate rudders. As an au- thorized license holder and partner,

Wärtsilä intends to fully integrate gate rudders within its propulsion product designs for all vessel classes and focus on global markets outside Japan.

ZF Condition Monitoring

ZF has introduced an intelligent

Condition Monitoring System for thrusters. The technology monitors the status of the thruster system and helps shipyards, shipping companies and ?eet operators maintain the safe-

Kongsberg Thrusters for ty and ef?ciency of their ships as well

Electric Tug as extend the service life of the pro-

Kongsberg Maritime will supply its pulsion system. In addition to that,

KONGSBERG US255 L PM FP az- PropCad 2020 a new oil cleaning system ensures oil imuth thrusters for a new fully-elec- HydroComp’s PropCad 2020 soft- quality and prolongs oil service life.

tric RSD-E Tug 2513 ship-handling ware for the geometric design of tug being built by Damen Shipyards marine propellers automatically

Group for the Ports of Auckland. prepares 2D drawings, 3D CAD

The thrusters, supplied from Kongs- models, and more. All HydroComp berg’s facility in Rauma, Finland will 2020 products have been upgraded provide a bollard pull capability of with a new internal code-and-con- 70 metric tons. With their integrat- trol to increase speed and stability. ed PM electric motors, maneuver- Other improvements include a re- ability, tough modular construction vised algorithm for CAD import, and reliability, the thrusters combine inclusion of the latest classi?cation minimal running costs with im- society rules and improved 3D ren- proved environmental credentials. dering speed and visuals.

May 2020 58

MN

57

57

59

59