Page 32: of Marine News Magazine (July 2020)

Propulsion Technology

Read this page in Pdf, Flash or Html5 edition of July 2020 Marine News Magazine

OFFSHORE WIND ing players and new entrants alike. We’ve already seen a num- ber of traditional offshore oil and gas players—from operators such as Shell, Total, Equinor and Repsol, all the way down the supply chain—transfer their skillset into the offshore wind market over the years. For these ?rms and others, including traditional offshore oil and gas players such as yards for jacket and HVDC substation fabrication, as well as for construction and assembly of ?oating foundations, opportunities abound as projects get larger, deeper and further from shore.

Offshore wind farms need servicing, creating even more work for a wide range of support providers—from boatbuild- ers to turbine technicians. In Europe, for example, onshore operation support bases are having associated positive impacts (long-term direct jobs, and bolstered local supply chains) in port regions that had been historically active but have strug- gled more recently due depressed oil and gas and shipping markets. Using the current UK $94,000/MW/year opera- tional expenditure (opex) cost, the current pipeline of projects could require up to $46.6 billion of annual opex spend within the next decade, says WER.

Ørsted

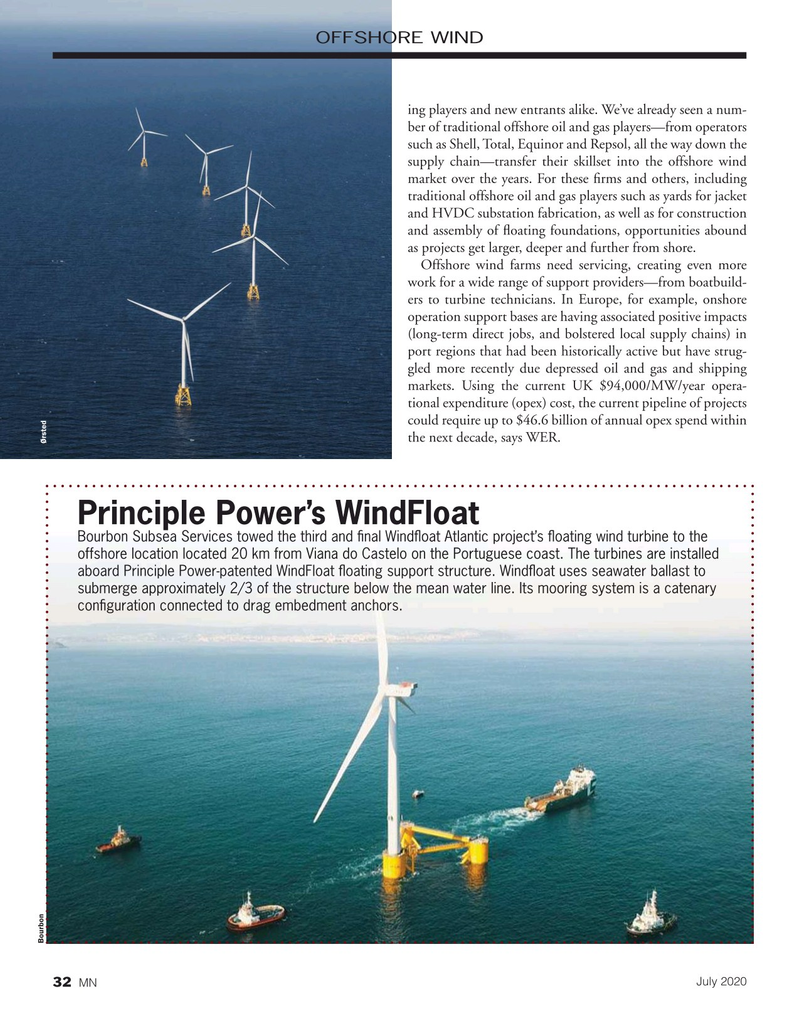

Principle Power’s WindFloat

Bourbon Subsea Services towed the third and ?nal Wind?oat Atlantic project’s ?oating wind turbine to the offshore location located 20 km from Viana do Castelo on the Portuguese coast. The turbines are installed aboard Principle Power-patented WindFloat ?oating support structure. Wind?oat uses seawater ballast to submerge approximately 2/3 of the structure below the mean water line. Its mooring system is a catenary con?guration connected to drag embedment anchors.

Bourbon

July 2020 32 MN

31

31

33

33