Page 49: of Marine News Magazine (July 2020)

Propulsion Technology

Read this page in Pdf, Flash or Html5 edition of July 2020 Marine News Magazine

Its applications are evident in numerous marine vessels, including in ships used in the offshore wind industry, as well as double-ended ferries, river vessels, tugs and mine- countermeasure vessels that require high maneuverability.

The VSP is an optimal solution for use in these applica- tions. Apart from the fact that the VSP gives a ship high maneuverability in any water conditions, it also offers high ef?ciency, robustness against ?oating debris and the good underwater acoustics.

The design and engineering of the VSP

A modern Carousel RAVE tug equipped with two Voith

Schneider Propellers, for example, creates very large forces at high and low speeds to perform its regular ship-assistance du- ties. Fuel consumption is minimal because mainly the hull is used to generate steering and breaking forces, and the VSPs are only on task, aligning the tug through high-precision con- trol functions.

As a cycloidal drive, the VSP is quite different from classic azimuth thrusters. Because of its unique positioning and the required design structures in the hull, Voith is highly involved in the design process for each VSP order. The process includes optimizing ship hulls through CFD testing and modeling. “Our goal is to fully integrate these propellers and support designers as they craft the hull to make the most of the VSP’s capabilities,” said Michael Palm, Head of Shiphydrodynamics at Voith Turbo Marine. “As a ?nal check before production, Bene?ts of the VSP the Voith team administers and analyzes a CFD propulsion

The maneuvering performance of cycloidal drives truly performance model, which then allows for additional updates stands out thanks to accurate dynamic positioning (DP). if needed. In addition to CFD calculations, Voith provides Even under rough environmental conditions, the VSP offers model propellers with a diameter of 200 mm, and these can amazing aquatic agility, especially during fast approaches and be used in international ship model basins.” departures from wind turbines and allowing for a safe and quick transfer of goods and personnel from offshore wind

Inside the VSP assembly farms. Comparative calculations by DNV GL (Marine Cy-

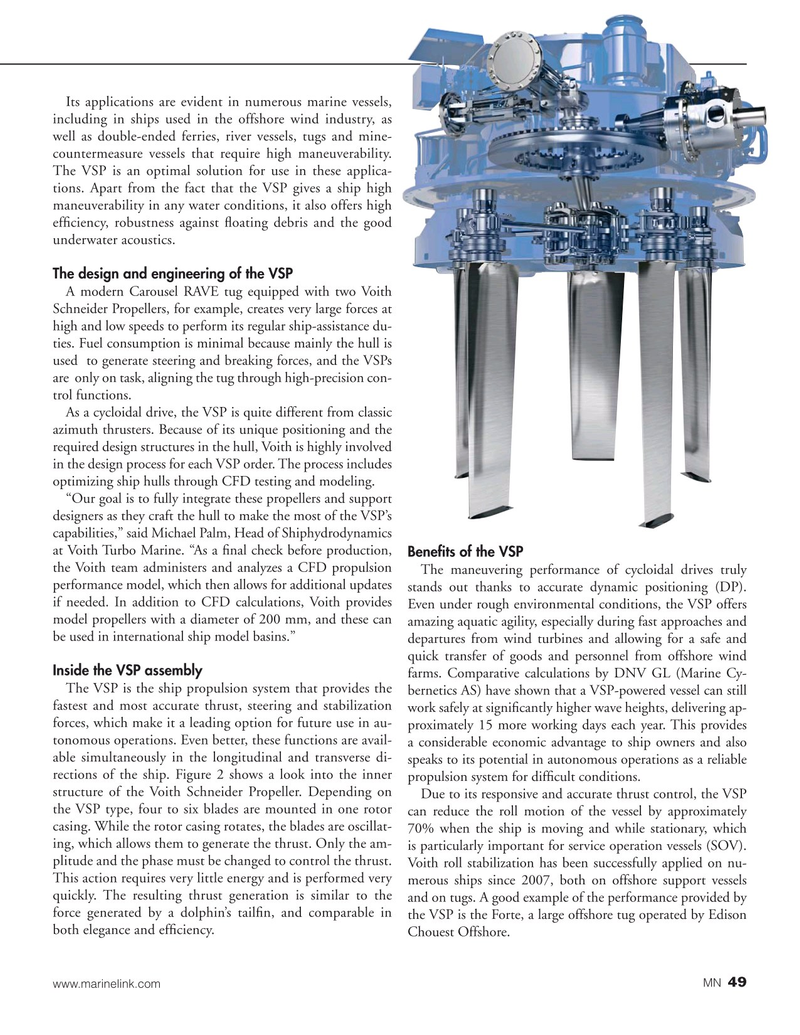

The VSP is the ship propulsion system that provides the bernetics AS) have shown that a VSP-powered vessel can still fastest and most accurate thrust, steering and stabilization work safely at signi?cantly higher wave heights, delivering ap- forces, which make it a leading option for future use in au- proximately 15 more working days each year. This provides tonomous operations. Even better, these functions are avail- a considerable economic advantage to ship owners and also able simultaneously in the longitudinal and transverse di- speaks to its potential in autonomous operations as a reliable rections of the ship. Figure 2 shows a look into the inner propulsion system for dif?cult conditions.

structure of the Voith Schneider Propeller. Depending on

Due to its responsive and accurate thrust control, the VSP the VSP type, four to six blades are mounted in one rotor can reduce the roll motion of the vessel by approximately casing. While the rotor casing rotates, the blades are oscillat- 70% when the ship is moving and while stationary, which ing, which allows them to generate the thrust. Only the am- is particularly important for service operation vessels (SOV). plitude and the phase must be changed to control the thrust. Voith roll stabilization has been successfully applied on nu-

This action requires very little energy and is performed very merous ships since 2007, both on offshore support vessels quickly. The resulting thrust generation is similar to the and on tugs. A good example of the performance provided by force generated by a dolphin’s tail?n, and comparable in the VSP is the Forte, a large offshore tug operated by Edison both elegance and ef?ciency.

Chouest Offshore.

49 www.marinelink.com MN

48

48

50

50