Page 24: of Marine News Magazine (October 2020)

Shipbuilding & Repair

Read this page in Pdf, Flash or Html5 edition of October 2020 Marine News Magazine

DESALINATION SYSTEMS

Durable and reliable high-pressure pumps As McGuire explains, often a Chief Engineer or ship

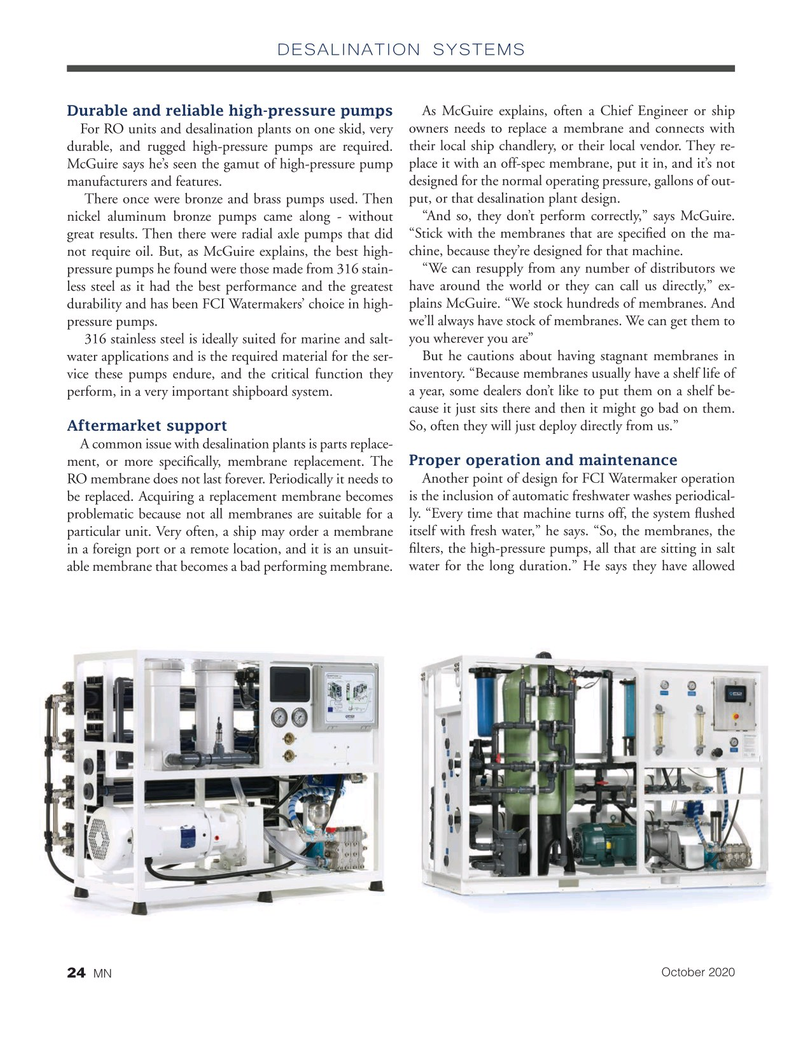

For RO units and desalination plants on one skid, very owners needs to replace a membrane and connects with durable, and rugged high-pressure pumps are required. their local ship chandlery, or their local vendor. They re-

McGuire says he’s seen the gamut of high-pressure pump place it with an off-spec membrane, put it in, and it’s not manufacturers and features. designed for the normal operating pressure, gallons of out- There once were bronze and brass pumps used. Then put, or that desalination plant design. nickel aluminum bronze pumps came along - without “And so, they don’t perform correctly,” says McGuire. great results. Then there were radial axle pumps that did “Stick with the membranes that are speci? ed on the ma- not require oil. But, as McGuire explains, the best high- chine, because they’re designed for that machine.

pressure pumps he found were those made from 316 stain- “We can resupply from any number of distributors we less steel as it had the best performance and the greatest have around the world or they can call us directly,” ex- durability and has been FCI Watermakers’ choice in high- plains McGuire. “We stock hundreds of membranes. And pressure pumps. we’ll always have stock of membranes. We can get them to 316 stainless steel is ideally suited for marine and salt- you wherever you are” water applications and is the required material for the ser- But he cautions about having stagnant membranes in vice these pumps endure, and the critical function they inventory. “Because membranes usually have a shelf life of perform, in a very important shipboard system. a year, some dealers don’t like to put them on a shelf be- cause it just sits there and then it might go bad on them.

Aftermarket support So, often they will just deploy directly from us.”

A common issue with desalination plants is parts replace- ment, or more speci? cally, membrane replacement. The Proper operation and maintenance

RO membrane does not last forever. Periodically it needs to Another point of design for FCI Watermaker operation be replaced. Acquiring a replacement membrane becomes is the inclusion of automatic freshwater washes periodical- problematic because not all membranes are suitable for a ly. “Every time that machine turns off, the system ? ushed particular unit. Very often, a ship may order a membrane itself with fresh water,” he says. “So, the membranes, the in a foreign port or a remote location, and it is an unsuit- ? lters, the high-pressure pumps, all that are sitting in salt able membrane that becomes a bad performing membrane. water for the long duration.” He says they have allowed

October 2020 24 MN

23

23

25

25