Page 55: of Marine News Magazine (November 2020)

Workboat Annual

Read this page in Pdf, Flash or Html5 edition of November 2020 Marine News Magazine

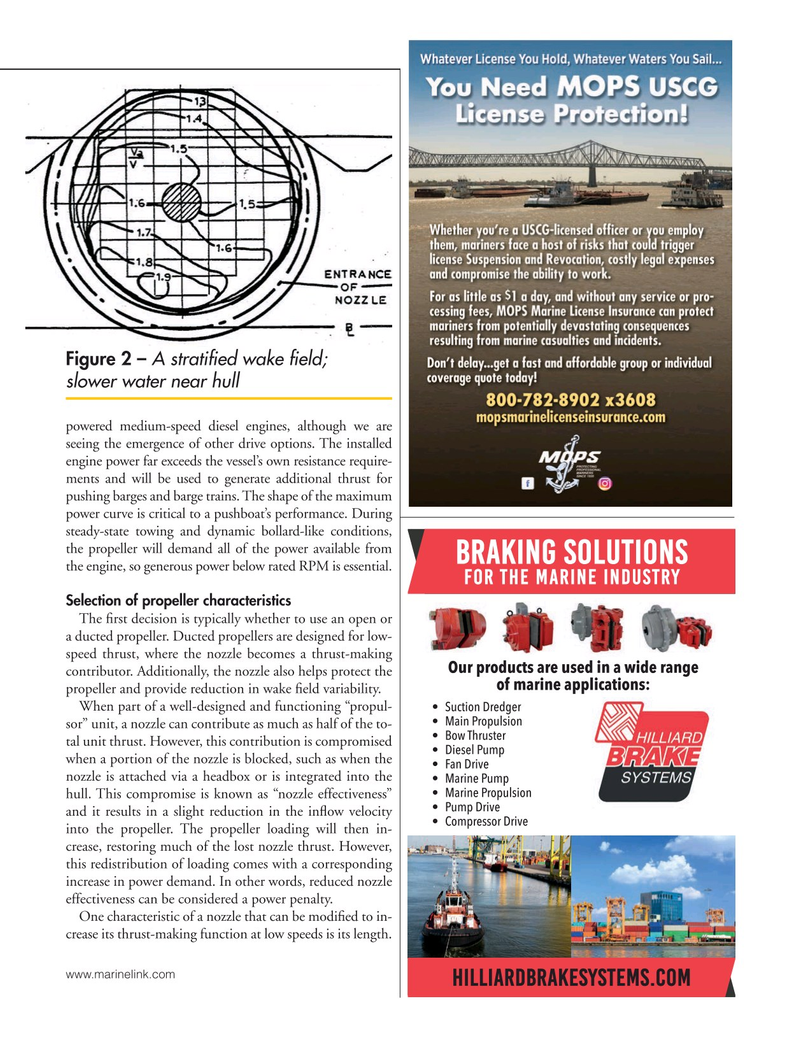

Figure 2 – A strati? ed wake ? eld; slower water near hull powered medium-speed diesel engines, although we are seeing the emergence of other drive options. The installed engine power far exceeds the vessel’s own resistance require- ments and will be used to generate additional thrust for pushing barges and barge trains. The shape of the maximum power curve is critical to a pushboat’s performance. During steady-state towing and dynamic bollard-like conditions, the propeller will demand all of the power available from the engine, so generous power below rated RPM is essential.

Selection of propeller characteristics

The ? rst decision is typically whether to use an open or a ducted propeller. Ducted propellers are designed for low- speed thrust, where the nozzle becomes a thrust-making contributor. Additionally, the nozzle also helps protect the propeller and provide reduction in wake ? eld variability.

When part of a well-designed and functioning “propul- sor” unit, a nozzle can contribute as much as half of the to- tal unit thrust. However, this contribution is compromised when a portion of the nozzle is blocked, such as when the nozzle is attached via a headbox or is integrated into the hull. This compromise is known as “nozzle effectiveness” and it results in a slight reduction in the in? ow velocity into the propeller. The propeller loading will then in- crease, restoring much of the lost nozzle thrust. However, this redistribution of loading comes with a corresponding increase in power demand. In other words, reduced nozzle effectiveness can be considered a power penalty.

One characteristic of a nozzle that can be modi? ed to in- crease its thrust-making function at low speeds is its length. www.marinelink.com

54

54

56

56