Page 13: of Marine News Magazine (January 2022)

Workboat Propulsion

Read this page in Pdf, Flash or Html5 edition of January 2022 Marine News Magazine

Column

Glosten ? cation

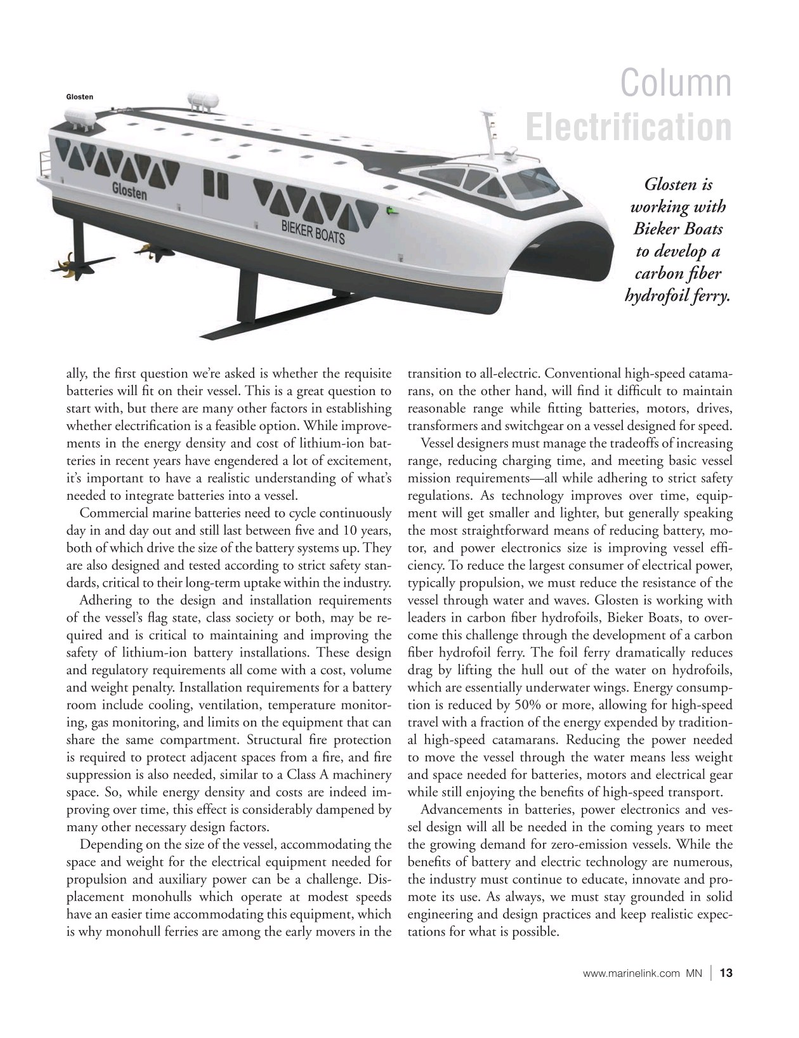

Glosten is working with

Bieker Boats to develop a carbon ? ber hydrofoil ferry. ally, the ? rst question we’re asked is whether the requisite transition to all-electric. Conventional high-speed catama- batteries will ? t on their vessel. This is a great question to rans, on the other hand, will ? nd it dif? cult to maintain start with, but there are many other factors in establishing reasonable range while ? tting batteries, motors, drives, whether electri? cation is a feasible option. While improve- transformers and switchgear on a vessel designed for speed.

ments in the energy density and cost of lithium-ion bat- Vessel designers must manage the tradeoffs of increasing teries in recent years have engendered a lot of excitement, range, reducing charging time, and meeting basic vessel it’s important to have a realistic understanding of what’s mission requirements—all while adhering to strict safety needed to integrate batteries into a vessel. regulations. As technology improves over time, equip-

Commercial marine batteries need to cycle continuously ment will get smaller and lighter, but generally speaking day in and day out and still last between ? ve and 10 years, the most straightforward means of reducing battery, mo- both of which drive the size of the battery systems up. They tor, and power electronics size is improving vessel ef? - are also designed and tested according to strict safety stan- ciency. To reduce the largest consumer of electrical power, dards, critical to their long-term uptake within the industry. typically propulsion, we must reduce the resistance of the

Adhering to the design and installation requirements vessel through water and waves. Glosten is working with of the vessel’s ? ag state, class society or both, may be re- leaders in carbon ? ber hydrofoils, Bieker Boats, to over- quired and is critical to maintaining and improving the come this challenge through the development of a carbon safety of lithium-ion battery installations. These design ? ber hydrofoil ferry. The foil ferry dramatically reduces and regulatory requirements all come with a cost, volume drag by lifting the hull out of the water on hydrofoils, and weight penalty. Installation requirements for a battery which are essentially underwater wings. Energy consump- room include cooling, ventilation, temperature monitor- tion is reduced by 50% or more, allowing for high-speed ing, gas monitoring, and limits on the equipment that can travel with a fraction of the energy expended by tradition- share the same compartment. Structural ? re protection al high-speed catamarans. Reducing the power needed is required to protect adjacent spaces from a ? re, and ? re to move the vessel through the water means less weight suppression is also needed, similar to a Class A machinery and space needed for batteries, motors and electrical gear space. So, while energy density and costs are indeed im- while still enjoying the bene? ts of high-speed transport. proving over time, this effect is considerably dampened by Advancements in batteries, power electronics and ves- many other necessary design factors. sel design will all be needed in the coming years to meet

Depending on the size of the vessel, accommodating the the growing demand for zero-emission vessels. While the space and weight for the electrical equipment needed for bene? ts of battery and electric technology are numerous, propulsion and auxiliary power can be a challenge. Dis- the industry must continue to educate, innovate and pro- placement monohulls which operate at modest speeds mote its use. As always, we must stay grounded in solid have an easier time accommodating this equipment, which engineering and design practices and keep realistic expec- is why monohull ferries are among the early movers in the tations for what is possible. www.marinelink.com MN 13|

12

12

14

14