Page 40: of Marine News Magazine (August 2023)

Boatbuilding & Repair

Read this page in Pdf, Flash or Html5 edition of August 2023 Marine News Magazine

Tech File

Shipyard Tools

Clean Technology Lasers: A New

Tool to Remove Corrosion and Scale

Laser systems quickly remove corrosion and scale from metal surfaces with less preparation and mess than traditional techniques.

By Del Williams

In the maritime industry, corrosion and scale (where but also prevent further corrosion and deterioration in- rust penetrates a metal surface) can quickly become an cluding possible premature failure.

issue in an outdoor, salt sea spray laden environment. Unfortunately, traditional techniques used for this pur-

When sea spray evaporates, it leaves salt behind, leading pose such as sandblasting and chemical stripping are of- to saltwater staining and accelerated corrosion. ten messy and require expensive consumables as well as

So, most shipbuilders as well as those responsible for substantial time for preparation and cleanup. Additionally, maintenance and repair understand the value of treating sandblasting and chemical stripping may not be feasible to metal surfaces to remove corrosion, scale and saltwater clean, maintain or recondition many of the ship’s interior staining, which is vital to maintain essential interior and and exterior spaces. These methods are also drawing scru- exterior components such as engines, generators, fuel tiny from regulators like the EPA and OSHA since they pumps, winches, anchoring chains, latches, door hinges can pose risks to applicators and the environment.

and locks. This is necessary to preserve not only function Although manual methods of cleaning and removal are available, such as chipping and using wire brushes and grinders, these are very labor intensive and time consuming.

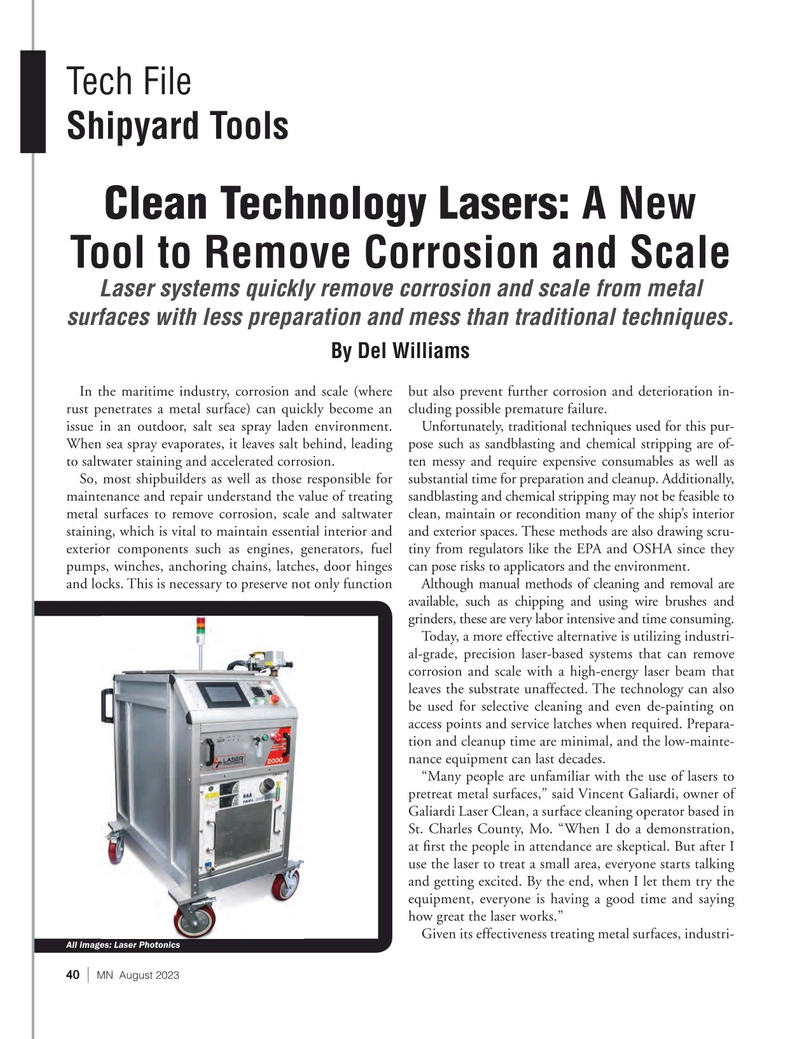

Today, a more effective alternative is utilizing industri- al-grade, precision laser-based systems that can remove corrosion and scale with a high-energy laser beam that leaves the substrate unaffected. The technology can also be used for selective cleaning and even de-painting on access points and service latches when required. Prepara- tion and cleanup time are minimal, and the low-mainte- nance equipment can last decades. “Many people are unfamiliar with the use of lasers to pretreat metal surfaces,” said Vincent Galiardi, owner of

Galiardi Laser Clean, a surface cleaning operator based in

St. Charles County, Mo. “When I do a demonstration, at ? rst the people in attendance are skeptical. But after I use the laser to treat a small area, everyone starts talking and getting excited. By the end, when I let them try the equipment, everyone is having a good time and saying how great the laser works.”

Given its effectiveness treating metal surfaces, industri-

All images: Laser Photonics 40 | MN August 2023

39

39

41

41