Page 42: of Marine News Magazine (August 2023)

Boatbuilding & Repair

Read this page in Pdf, Flash or Html5 edition of August 2023 Marine News Magazine

Tech File

Shipyard Tools jects of rust, paint and contaminants to bare metal. lando, Fla.-based Laser Photonics, a provider of patented

However, for operators, exposure to corrosive acids and industrial grade CleanTech laser systems for cleaning and noxious chemical fumes is inherently dangerous. The surface conditioning. The American-made systems func- process can also be time-consuming to prepare the prop- tion either as mobile standalone units or can be integrat- er chemical bath, achieve the required level of cleaning, ed into production lines. and dispose of the waste. In addition, disposing of toxic The laser systems are available in portable and stationary chemicals is costly and closely regulated by agencies like models ranging from 50 to 3,000 watts (a 4,000-watt ver-

OSHA and the EPA. sion is in development) with chamber sizes from 3’ x 3’ in size to 6’ x 12’. The systems can also be installed in manu-

Safe, effective laser cleaning facturing lines in cabinets or operated by a robotic arm.

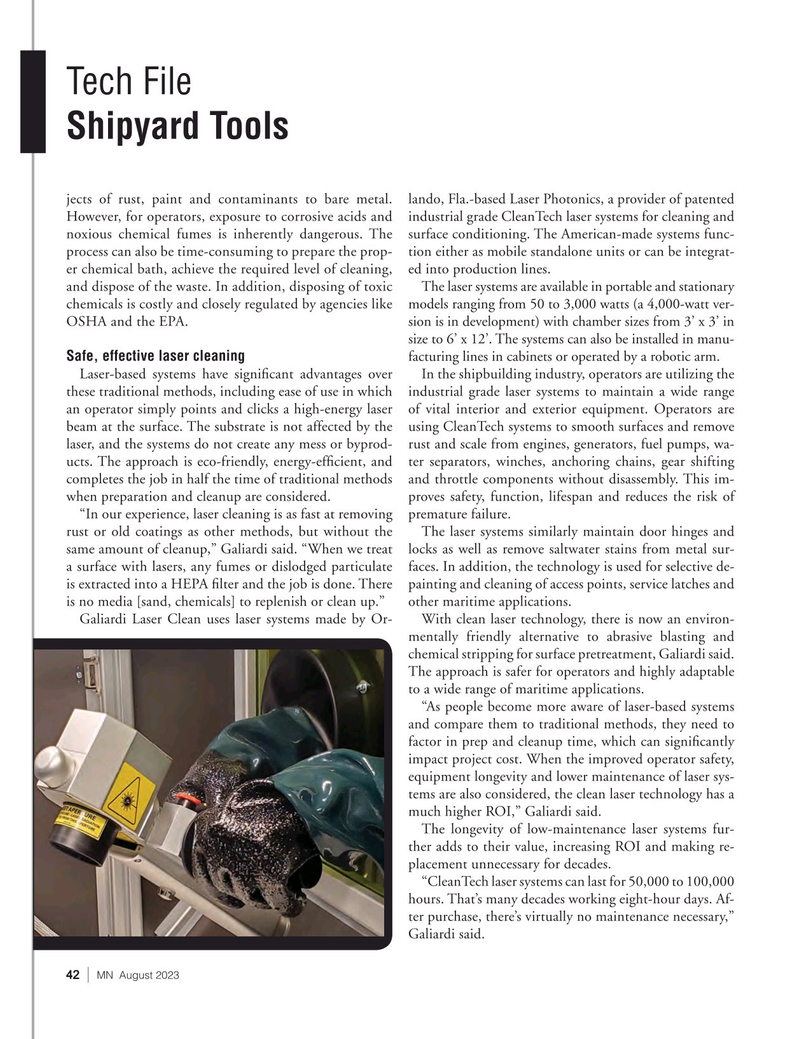

Laser-based systems have signi? cant advantages over In the shipbuilding industry, operators are utilizing the these traditional methods, including ease of use in which industrial grade laser systems to maintain a wide range an operator simply points and clicks a high-energy laser of vital interior and exterior equipment. Operators are beam at the surface. The substrate is not affected by the using CleanTech systems to smooth surfaces and remove laser, and the systems do not create any mess or byprod- rust and scale from engines, generators, fuel pumps, wa- ucts. The approach is eco-friendly, energy-ef? cient, and ter separators, winches, anchoring chains, gear shifting completes the job in half the time of traditional methods and throttle components without disassembly. This im- when preparation and cleanup are considered. proves safety, function, lifespan and reduces the risk of “In our experience, laser cleaning is as fast at removing premature failure.

rust or old coatings as other methods, but without the The laser systems similarly maintain door hinges and same amount of cleanup,” Galiardi said. “When we treat locks as well as remove saltwater stains from metal sur- a surface with lasers, any fumes or dislodged particulate faces. In addition, the technology is used for selective de- is extracted into a HEPA ? lter and the job is done. There painting and cleaning of access points, service latches and is no media [sand, chemicals] to replenish or clean up.” other maritime applications.

Galiardi Laser Clean uses laser systems made by Or- With clean laser technology, there is now an environ- mentally friendly alternative to abrasive blasting and chemical stripping for surface pretreatment, Galiardi said.

The approach is safer for operators and highly adaptable to a wide range of maritime applications.

“As people become more aware of laser-based systems and compare them to traditional methods, they need to factor in prep and cleanup time, which can signi? cantly impact project cost. When the improved operator safety, equipment longevity and lower maintenance of laser sys- tems are also considered, the clean laser technology has a much higher ROI,” Galiardi said.

The longevity of low-maintenance laser systems fur- ther adds to their value, increasing ROI and making re- placement unnecessary for decades.

“CleanTech laser systems can last for 50,000 to 100,000 hours. That’s many decades working eight-hour days. Af- ter purchase, there’s virtually no maintenance necessary,”

Galiardi said.

42 | MN August 2023

41

41

43

43