Page 28: of Marine News Magazine (October 2024)

Read this page in Pdf, Flash or Html5 edition of October 2024 Marine News Magazine

Feature

Offshore reduce overall ef? ciency. In addition, feeder vessels are it allows WTIVs to remain on-site, maximizing their time more prone to weather disruptions, present additional risk spent installing components and reducing the idle time wait- in terms of stability and collisions, and increase the han- ing for parts to be delivered. In addition, under certain cir- dling (and exposure to damage) of delicate components. cumstances, it can serve as a workaround for port restrictions

In the U.S. context, where no U.S.-built WTIVs are or the challenge of transporting unique foundation designs.

presently available, the added costs and challenges associ- As such, the U.S. offshore wind industry, although it faces ated with feedering are unavoidable—for now. Once op- many ongoing challenges ahead, has a business-critical path erational, likely in 2025, the U.S.-built WTIV Charybdis available for implementation: the feedering model. Although will be able to both transport and install turbine compo- this model is more complex, typically more expensive, and has nents. But there will be challenges, including port infra- a higher risk than the traditional energy supply model used structure limitations that prevent access for large WTIVs. for decades in many other areas of the world, it is necessary.

In addition, a sole Jones Act installation vessel cannot meet the needs of an entire industry that sees its project pipeline Advancements in technology growing. Feedering will still be a necessity. One of the biggest bottlenecks in the U.S. offshore wind

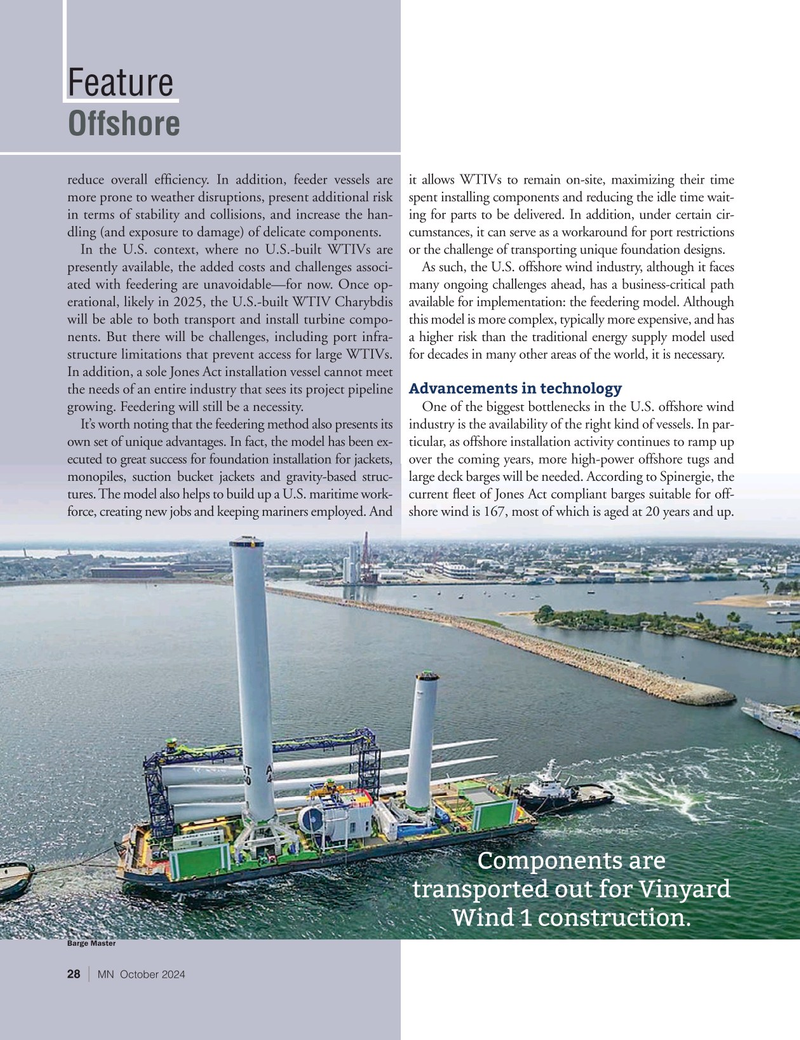

It’s worth noting that the feedering method also presents its industry is the availability of the right kind of vessels. In par- own set of unique advantages. In fact, the model has been ex- ticular, as offshore installation activity continues to ramp up ecuted to great success for foundation installation for jackets, over the coming years, more high-power offshore tugs and monopiles, suction bucket jackets and gravity-based struc- large deck barges will be needed. According to Spinergie, the tures. The model also helps to build up a U.S. maritime work- current ? eet of Jones Act compliant barges suitable for off- force, creating new jobs and keeping mariners employed. And shore wind is 167, most of which is aged at 20 years and up.

Components are transported out for Vinyard

Wind 1 construction.

Barge Master 28 | MN October 2024

27

27

29

29