Page 29: of Marine Technology Magazine (January 2012)

Offshore Inspection, Repair & Maintenance

Read this page in Pdf, Flash or Html5 edition of January 2012 Marine Technology Magazine

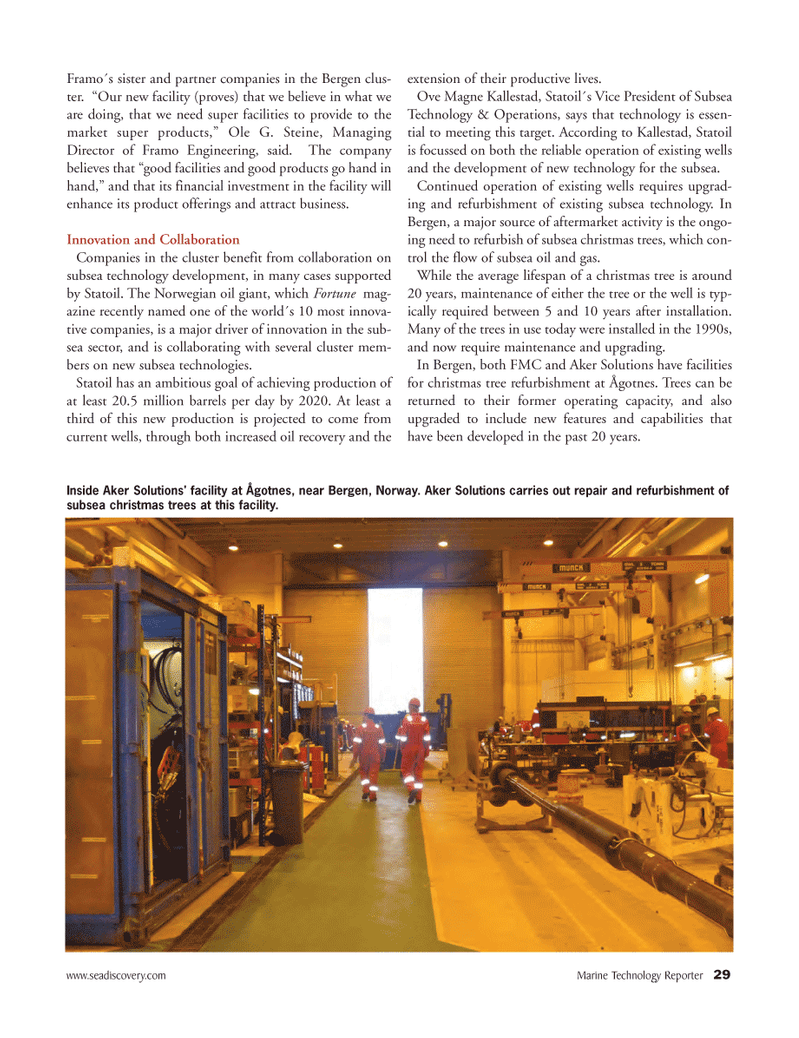

www.seadiscovery.com Marine Technology Reporter 29Framo´s sister and partner companies in the Bergen clus- ter. ?Our new facility (proves) that we believe in what we are doing, that we need super facilities to provide to the market super products,? Ole G. Steine, Managing Director of Framo Engineering, said. The company believes that ?good facilities and good products go hand in hand,? and that its financial investment in the facility will enhance its product offerings and attract business. Innovation and Collaboration Companies in the cluster benefit from collaboration on subsea technology development, in many cases supported by Statoil. The Norwegian oil giant, which Fortune mag-azine recently named one of the world´s 10 most innova- tive companies, is a major driver of innovation in the sub- sea sector, and is collaborating with several cluster mem- bers on new subsea technologies. Statoil has an ambitious goal of achieving production of at least 20.5 million barrels per day by 2020. At least a third of this new production is projected to come from current wells, through both increased oil recovery and the extension of their productive lives. Ove Magne Kallestad, Statoil´s Vice President of Subsea Technology & Operations, says that technology is essen- tial to meeting this target. According to Kallestad, Statoil is focussed on both the reliable operation of existing wells and the development of new technology for the subsea. Continued operation of existing wells requires upgrad- ing and refurbishment of existing subsea technology. In Bergen, a major source of aftermarket activity is the ongo- ing need to refurbish of subsea christmas trees, which con- trol the flow of subsea oil and gas. While the average lifespan of a christmas tree is around 20 years, maintenance of either the tree or the well is typ- ically required between 5 and 10 years after installation. Many of the trees in use today were installed in the 1990s, and now require maintenance and upgrading. In Bergen, both FMC and Aker Solutions have facilities for christmas tree refurbishment at Ågotnes. Trees can be returned to their former operating capacity, and also upgraded to include new features and capabilities that have been developed in the past 20 years. Inside Aker Solutions' facility at Ågotnes, near Bergen, Norway. Aker Solutions carries out repair and refurbishment of subsea christmas trees at this facility. MTR#1 (18-33):MTR Layouts 1/3/2012 10:23 AM Page 29

28

28

30

30