Page 30: of Marine Technology Magazine (January 2012)

Offshore Inspection, Repair & Maintenance

Read this page in Pdf, Flash or Html5 edition of January 2012 Marine Technology Magazine

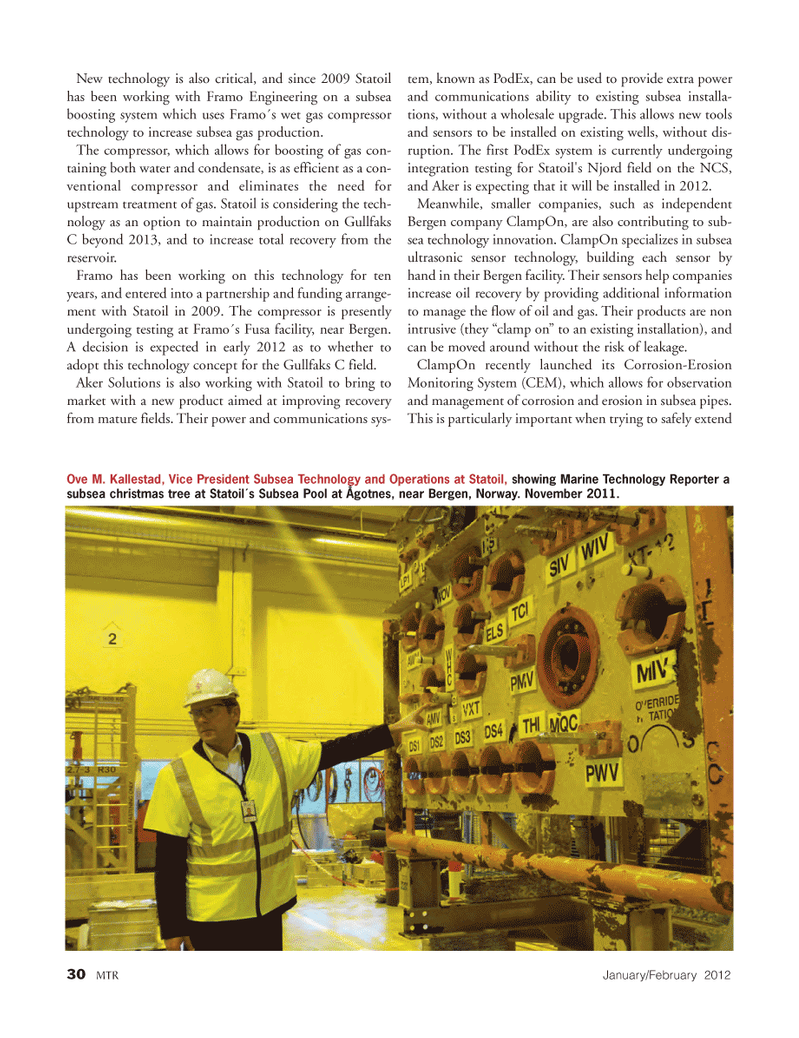

30MTRJanuary/February 2012 New technology is also critical, and since 2009 Statoil has been working with Framo Engineering on a subsea boosting system which uses Framo´s wet gas compressor technology to increase subsea gas production. The compressor, which allows for boosting of gas con- taining both water and condensate, is as efficient as a con-ventional compressor and eliminates the need for upstream treatment of gas. Statoil is considering the tech- nology as an option to maintain production on Gullfaks C beyond 2013, and to increase total recovery from the reservoir. Framo has been working on this technology for ten years, and entered into a partnership and funding arrange- ment with Statoil in 2009. The compressor is presently undergoing testing at Framo´s Fusa facility, near Bergen. A decision is expected in early 2012 as to whether toadopt this technology concept for the Gullfaks C field. Aker Solutions is also working with Statoil to bring to market with a new product aimed at improving recovery from mature fields. Their power and communications sys- tem, known as PodEx, can be used to provide extra power and communications ability to existing subsea installa-tions, without a wholesale upgrade. This allows new tools and sensors to be installed on existing wells, without dis- ruption. The first PodEx system is currently undergoing integration testing for Statoil's Njord field on the NCS, and Aker is expecting that it will be installed in 2012. Meanwhile, smaller companies, such as independent Bergen company ClampOn, are also contributing to sub- sea technology innovation. ClampOn specializes in subsea ultrasonic sensor technology, building each sensor by hand in their Bergen facility. Their sensors help companies increase oil recovery by providing additional information to manage the flow of oil and gas. Their products are non intrusive (they ?clamp on? to an existing installation), and can be moved around without the risk of leakage. ClampOn recently launched its Corrosion-Erosion Monitoring System (CEM), which allows for observation and management of corrosion and erosion in subsea pipes. This is particularly important when trying to safely extend Ove M. Kallestad, Vice President Subsea Technology and Operations at Statoil, showing Marine Technology Reporter a subsea christmas tree at Statoil´s Subsea Pool at Ågotnes, near Bergen, Norway. November 2011. MTR#1 (18-33):MTR Layouts 1/3/2012 10:24 AM Page 30

29

29

31

31