Subsea: Standardization is the New Innovation

As one of the world’s most technologically innovative industries, the highly specialized subsea sector is not typically known for standardized operations. But that is changing.

Companies like Statoil, the world’s second largest subsea operator, have traditionally achieved success by pushing the boundaries to what is possible under water, frequently going “longer, deeper and colder.”

But as the complexity of global subsea projects grows, so too does the bill for contractors, suppliers, operators, engineers, researchers and just about everyone involved in subsea projects. Many believe that this doesn’t have to be the case. According to some of the leading companies in Norway’s vibrant subsea cluster, including Statoil, standardization is an effective way to generate cost savings in even the most complex projects.

Standardization does not necessarily mean innovation is stifled. Rather, instead of spending costly engineering hours working toward the next grand, over-over-the-top subsea solution, industry leaders are striving for smart, simple answers to some of the sector’s largest challenges. This means innovation comes in the form of quick and effective, yet less costly, solutions that do not sacrifice quality.

Statoil’s Fast Track work process, for example, adds “simple, standard and cheaper” to “longer, deeper and colder,” said Torger Rød, Statoil’s SVP for Subsea, Pipelines and Cessation. The program essentially fuses tailored innovations with standardized solutions to develop and begin subsea production within a 30-month timeframe.

Under this accelerated method, product specifications are simplified, existing designs are reused when possible and concepts are chosen from a preexisting catalog, eliminating the concept selection phase, Rød explained. With Fast Track, the company reports a 40% shorter execution time, a low breakeven level of $40/boe and average IRR (nom) greater than 25%.

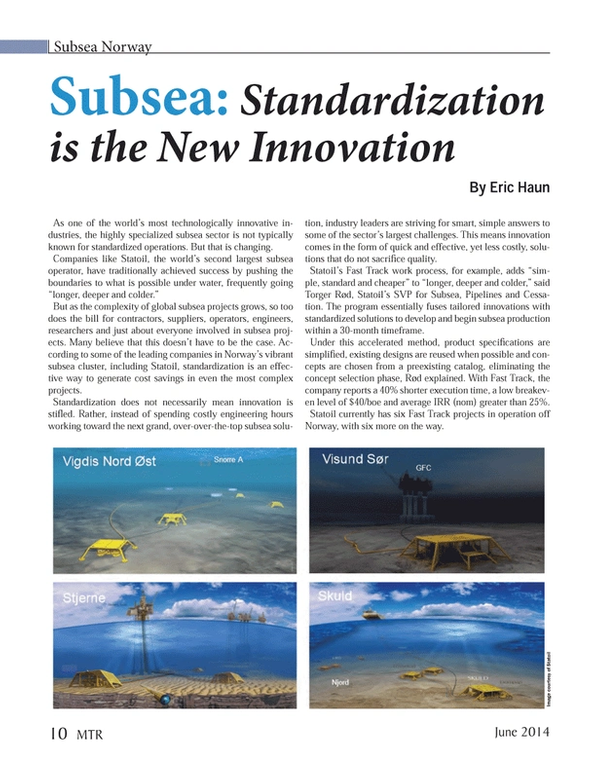

Statoil currently has six Fast Track projects in operation off Norway, with six more on the way.

(As published in the June 2014 edition of Marine Technology Reporter - http://www.marinetechnologynews.com/Magazine)

Read Subsea: Standardization is the New Innovation in Pdf, Flash or Html5 edition of June 2014 Marine Technology

Other stories from June 2014 issue

Content

- Editor's Note: MTR June 2014 page: 6

- Several Contracts for DOF Subsea page: 8

- Subsea: Standardization is the New Innovation page: 10

- Subsea Risk Management in Real Time page: 12

- Maersk Computer Game to Spark Students' Interest in Science page: 14

- FORCE: Tidal Project Begins Construction on Subsea Platform page: 18

- AUVs are Central to Lisbon Security Program page: 18

- Study: Rising Sea Level Puts 150 Million at Risk page: 22

- Insights into Inertial Sensor Technology page: 26

- ONR and the Culture of Innovation and Invention page: 30

- Preparing Engineers for Lucrative Ocean Related Careers page: 38

- C-MAR DP Training in Brazil page: 40

- Exceptional Imagery via Bluefin Robotics AUV & Sonardyne Solstice page: 42

- Oil Majors Increasingly Employ eLearning Tools page: 44

- VectorNav Launches VN-300 page: 53

- Trelleborg Debuts Thermal Insulation Portfolio page: 54

- Subsea Camera from Battelle page: 55

- MacArtney Launches LUXUS Dropplate page: 55

- WFS: Improved Subsea Video Camera page: 56

- GPRS Enabled Security Camera from OSIL page: 56

- Sonar Image Stabilization – A Powerful Tool page: 57

- Bowtech Releases New Tooling Camera Range page: 57

- Imenco and High Resolution Subsea Digital Imaging page: 57

- Axis: New Security Cameras page: 58

- New Submersible Pressure Sensor from AST page: 59

- Sonardyne System to Monitor North Sea CO2 Leaks page: 59