Sailbuoy Takes Off

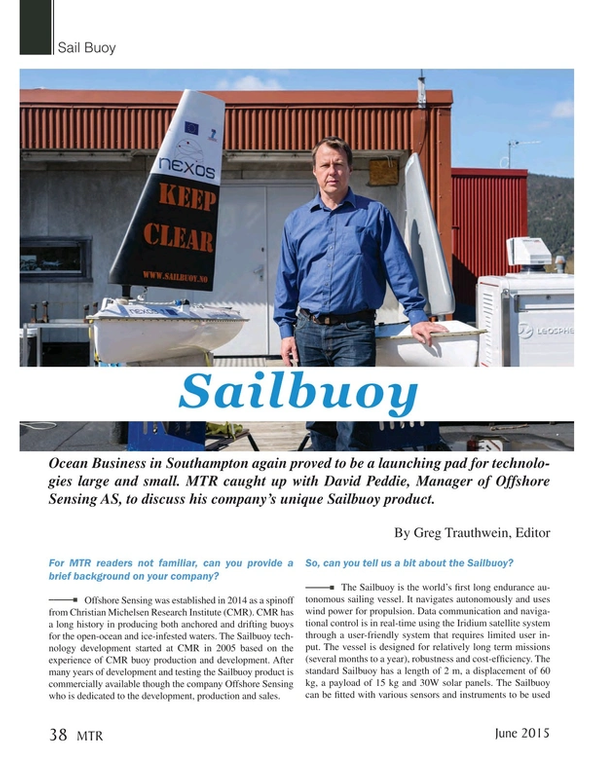

Ocean Business in Southampton again proved to be a launching pad for technologies large and small. MTR caught up with David Peddie, Manager of Offshore Sensing AS, to discuss his company’s unique Sailbuoy product.

For MTR readers not familiar, can you provide a brief background on your company?

Offshore Sensing was established in 2014 as a spinoff from Christian Michelsen Research Institute (CMR). CMR has a long history in producing both anchored and drifting buoys for the open-ocean and ice-infested waters. The Sailbuoy technology development started at CMR in 2005 based on the experience of CMR buoy production and development. After many years of development and testing the Sailbuoy product is commercially available though the company Offshore Sensing who is dedicated to the development, production and sales.

So, can you tell us a bit about the Sailbuoy?

The Sailbuoy is the world’s first long endurance autonomous sailing vessel. It navigates autonomously and uses wind power for propulsion. Data communication and navigational control is in real-time using the Iridium satellite system through a user-friendly system that requires limited user input. The vessel is designed for relatively long term missions (several months to a year), robustness and cost-efficiency. The standard Sailbuoy has a length of 2 m, a displacement of 60 kg, a payload of 15 kg and 30W solar panels. The Sailbuoy can be fitted with various sensors and instruments to be used for a wide variety of ocean applications including near-surface temperature, salinity and oxygen concentration monitoring, wave measurements and acoustic communication. The Sailbuoy is designed to be easily deployed and retrieved by untrained personnel from small to large vessels.

In brief, walk us through the rationale to design this vessel … what problem was it developed to solve?

CMR has a long history in producing drifting buoys. The advantage of drifting surface buoys is that they are relatively cheap, easy to deploy and allow for satellite communication. The rationale for the Sailbuoy came from designing a drifting surface buoy that does not drift out of the area of interest but is able to keep station without a mooring. It was initially designed to fulfil the objective of moored buoys while keeping the simplicity and low deployment costs of drifting buoys. However, we quickly found that, in addition to keeping station, it could travel efficiently along transects.

Specifically, how is the Sailbuoy designed to work?

The Sailbuoy is designed to harvest the wind power to sail, and to collect data from sensors while following a track or while station keeping in the open ocean. Inherent to the design is the high degree of autonomy. It requires little input from the user and is designed to solve most issues automatically. In effect this means that the user input is reduced to just giving it a track to follow. Data is then displayed in real-time through the user interface. Deployment and retrieval is also designed to be straightforward without the need for a crane or a large vessel.

An important aspect is that the Sailbouy was designed in Bergen, Norway for North sea and Norwegian sea conditions. These areas have often severe wind and waves in addition to limited solar power during winter. An autonomous vessel designed for these conditions has to sail well in light to severe conditions, and hardly use any energy doing it. This is the design background for the vehicle. Designing a vessel for light conditions and sunny weather would not be adequate for Norwegian waters. Using this as the backdrop, the Sailbuoy is designed to handle all North Sea conditions for months on end and to sail well in most of them. As for the limited sun energy during the winter, the power consumption of the Sailbuoy is so small that it can navigate without sun energy for months.

What differentiates Sailbuoy from others in the market?

Sailbuoy is a long endurance wind driven vessel, low-cost, user friendly, and modular. It is designed and proven for robustness with the ability to survive and operate in very rough environmental conditions and can navigate for months with little or no solar power, which is a great advantage for use in high latitudes. In reality this means that there is no risk of losing navigational capabilities or communication due to flat batteries. It will always be online and active regardless of energy harvesting. Due to its small draft it is suitable for shallow waters to 1m depth and it can withstand collisions with ice or floating debris without breaking up, getting entangled or pulled under.

Are there any new or innovative use technologies on your vessel that we won’t see on others? Please be specific.

From my background as an electronic/software engineer the Sailbuoy contains state-of-the-art low power electronics. In fact the electronics is not based on standard off the shelf boards but designed from the ground up specifically for use in the Sailbuoy. Every electronic component is chosen specifically for this purpose and all the software code is written to be as efficient and reliable as possible. Power consumption and reliability has been guiding the Sailbuoys design from the beginning.

In looking at your vessel and its capabilities, rank the top markets and/or niches you see it serving best, with short descriptions explaining why.

Acoustic data retrieval from subsea instruments in real time: Acoustic communications enable continuous data collection with a huge potential impact on research (data recovery from conventional moorings) and oil-gas industry (monitoring of leakage, corrosion and pig - logging). Data retrieval provides operators and scientists with valuable and timely information, and further increases security and reduces risk of pollution, emissions and economic loss.

Wave measurements: Wave measurements with spatial and temporal flexibility is a huge advantage for offshore oil and gas operations. From the science perspective measurements are scarce, and near shore regions are particularly important and undersampled.

Oil spill monitoring and detection: In situ mapping and tracking of oil concentration in low visibility and poor weather conditions is a significant asset because present remote sensing operations for monitoring of oil slicks are hindered by poor visibility, high sea state and wind conditions

Environmental monitoring and water quality: Sailbuoy can be fitted with sensors for water quality measurements, including conductivity, temperature sensor, oxygen optode and a fluorometer. Applications include detection of hydrocarbons, algae or chlorophyll-a activity, water turbidity, dissolved organic matter or chemical dyes. High-quality measurements of sea surface temperature and salinity over vast regions can be used to verify satellite remote sensing measurements, and to constrain numerical models.

What did you see in the world … in the autonomous vessel world … that told you that this was a good time to invest in a new system.

The investment of the system has been going on for 10 years, however we now see that AUVs, UAVs and Gilders are becoming widely used and the market now realises that autonomous vehicles can provide cost effective and risk reducing solutions.

When you look at the world – by region or market niche – where do you see opportunity and why?

Basically the Sailbuoy is well adapted for all open ocean areas, including large inland lakes.

However the Sailbuoy is best used in areas with low shipping density, to avoid the risk of collision and theft. It is also well suited for the high latitudes due to its unique features of power consumption and robustness.

What was the greatest challenge in bringing this vehicle from a concept to reality?

The greatest technical challenge was to enable it to navigate in storm and hurricane conditions and to withstand the severe weather in the north sea for months on end. Since the Sailbuoy is a new design for a new market it was a great challenge to get funding for further development. It was difficult to convince people that autonomous vessels is the way of the future. We received great help from The Norwegian Research council and internal funding at CMR to bring this vehicle to market.

What do you envision will be the greatest challenge in bringing this vehicle from reality to market success?

The challenge is to educate people about the advantages of using autonomous vehicles. The market is quite conservative and new technology takes a while to become understood and the advantages apparent to the customers.

Can you discuss how Sailbuoy is currently active in the world?

We have had a number of mission over the years, one in particular would be the Gulf of Mexico mission conducted by Met.no and the Universtity of Talahassey March – May, 2013. This mission lasted for two months and where surface temperature, salinity and dissolved oxygen measurements were made. This was a scientific mission where 1) the validity and usefulness of Sailbuoy measurements and the instrument’s utility in evaluating fields produced by different ocean models and 2) the potential of the Sailbuoy for mapping a large-scale river plume, which would be challenging or costly with conventional ship surveys and/or remote sensing were demonstrated.

(As published in the June 2015 edition of Marine Technology Reporter - http://www.marinetechnologynews.com/Magazine)

Read Sailbuoy Takes Off in Pdf, Flash or Html5 edition of June 2015 Marine Technology

Other stories from June 2015 issue

Content

- Van Oord Develops Deep Excavation System page: 10

- Unmanned Systems Work Together from Single Controller page: 14

- No Well Left Behind page: 16

- ABB Equipment for High-tech Ocean Simulator page: 20

- Retrieving Valuable Cargo from the Seabed page: 22

- AUV Monitors Environment at Underwater Mine page: 23

- A New Age for Underwater Autonomy page: 32

- Sailbuoy Takes Off page: 38

- Meet the Seastick page: 42

- Dredging Mega Projects page: 48

- MakaiLay Suite for Cable Layers page: 56

- BIRNS Millennium Series page: 58

- Linden Photonics Adds Hybrid Cables page: 58

- Geospace Offshore: Cabling, Umbilical Solutions page: 58

- BIRNS Aquamate page: 58

- Seacon’s Micro WET-CON page: 58

- In-situ Subsea Cable Repair page: 59

- Seacon’s Hydralight Connector page: 59

- TE Subcom on the 'Open Cables' Model page: 60

- South Bay Cable page: 60

- CS-MS’ Connector Range for ROVs page: 60

- Hydro Group: Underwater Connectors for Any Application page: 60

- Nexans' Cables page: 61

- Teledyne Cable Solutions page: 61

- Outland Technology page: 61