Klein's Side Scan Sonar, Then and Now

By Eric Haun

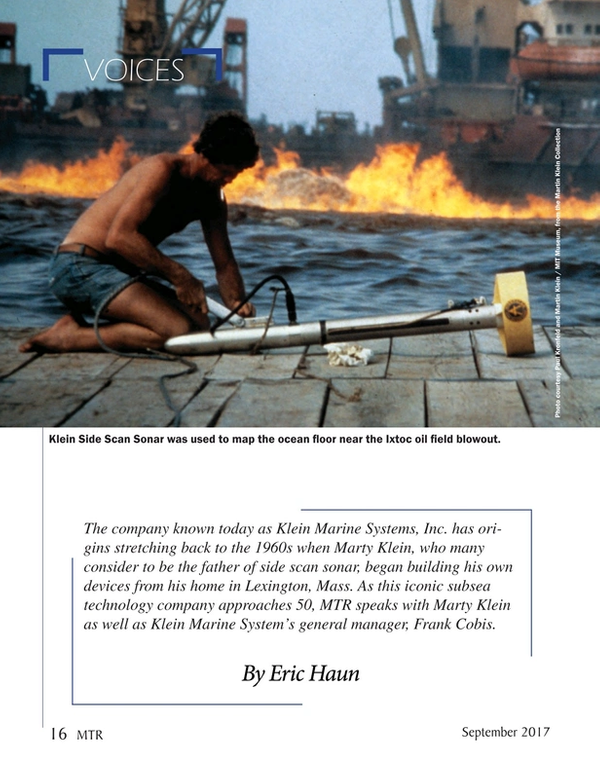

The company known today as Klein Marine Systems, Inc. has origins stretching back to the 1960s when Marty Klein, who many consider to be the father of side scan sonar, began building his own devices from his home in Lexington, Mass. As this iconic subsea technology company approaches 50, MTR speaks with Marty Klein as well as Klein Marine System’s general manager, Frank Cobis.

When did you realize you were destined for a career in the subsea world?

Marty Klein: Wow. It started back in 1961 when I was a senior at MIT and I had to do a thesis. I like to build things, but I seemed destined to work on some very theoretical project. I knew of Harold Edgerton, the famous professor, and I went into his lab and asked if he had anything interesting that I might work on. He introduced me to his world and partly to the ocean world, and I think I was hooked right from the beginning.

What kind of projects was [Edgerton] working on at the time?

MK: Edgerton was famous for the development of strobe light – he’s known as “Papa Flash” – but back in the late ’50s he was introduced to Jacques Cousteau by the National Geographic Society. Cousteau wanted to take pictures in the deepest part of the ocean. Edgerton wound up making him a deepwater camera and strobe light, and together they took the first pictures in the deep ocean. Edgerton’s device used a precision timed pinger that helped him to get these first deepwater pictures. Edgerton noticed that his pinger was penetrating the bottom of the seafloor a little bit. He began a fascination himself with underwater things – underwater cameras, strobes, sonar, boomers and other devices – and was working on a device he called a “mud penetrator”. It was just a converted navy echosounder that he was pulsing to look through the sediment of the Charles River in Boston and Boston Harbor, and sort of by coincidence I came onto this scene.

As a teenager I had been an electronics hobbyist. I had some experience working on these new devices called transistors, and I was able to improve the signals on Edgerton’s devices. At some point Edgerton turned his pinger, and instead of pointing it down he pointed it sideways and he made kind of a crude side scan sonar. I was working with him – first I worked in his lab and then he had had a company Edgerton, Germeshausen and Grier, which later became EG&G, Inc. The Oceanographic Department at E.G.& G. evolved and nowadays it has transformed into EdgeTech. And this sonar did pick up things on the seabed, but it made very crude pictures. We used the technology when the submarine Thresher sank in April of 1963, searching from the Bathyscaph Trieste. We worked very hard on that sonar device, and to make a long story short, it failed. The resolution was not good, and it had some other problems. So I was determined to make a real side scan sonar that would make pictures so that a shipwreck looked like a shipwreck and airplane looked like an airplane and a pipeline looked like a pipeline. I was obsessed with making that happen.

How did you take the crude sonar and turn it into something more useful?

MK: Some of the technology existed in various places, [such as] in the military and in research institutions. But the idea was to go to a much higher frequency and to go to a very different beam shape. Whereas the original device was just used in a 30 degree cone shape and a low frequency of 12 kilocycles, as we called them in those days, I went to high frequencies. The first one I built was 260 kilohertz, with a beam that was narrow in the horizontal plane and wide in the vertical plane. And also beams that look out to both sides of the ship rather than just pointing in one direction. So it involves going to higher frequency using a very short pulse length and using a specially shaped beam in a towed vehicle that was towed near the seafloor to make much better pictures.

From there, what was your vision?

MK: I made the side scan sonar at EG&G and introduced it to the world 50 years ago at a Marine Technology Society meeting in San Diego. EG&G started making a product that was very successful. There were some problems working at a big company. I never quite received the support that I wanted . . . and I had ideas to make better equipment, to improve it, to make other kinds of equipment, and I took the lead. I had no background at all in business, no education in business. I took a tremendous leap and started my little business when I was living in a tiny rented home in Lexington, Mass., and I literally started my company in the basement of this little home. In 1969 I moved the company to an old lumberyard in Salem, N.H. where there was room to expand. The rest is history. They are still there. Although I’ve been gone for a long time, the company is still there and they’re doing really good things. The company is now called Klein Marine Systems, Inc., a division of Mitcham Industries.

What were some of the earlier projects you were involved in when you started your company?

MK: The projects involved both equipment and expeditions. I went on all sorts of expeditions, both before and after I started the company. A lot of them I didn’t go; my customers went. All kinds of shipwrecks were found, for example the Hamilton and Scourge, the War of 1812 ships in Lake Ontario; the space shuttle Challenger; a lot of airplane wrecks were found. One of our biggest projects: I went Loch Ness a number of times and had some interesting projects there. Among other things, I found a Wellington bomber from World War II that was since raised and put in a museum in Brooklands in England. We were involved with Bob Ballard in the search for Titanic. We were involved with the search for the Edinburgh that held gold bars from Russia. We were involved with the De Braak. We were involved with the Atocha, the famous treasure ship.

In the last 50 years surely a lot has changed in marine technology. What are some of the most important technological advancements at your company and for your products in particular?

MK: There have been many changes over the years. In some ways the basic sonar – the basic technique – is not that different than it was years ago. There are fancier versions being made. One of the things we did over the years is make ones with dual frequency. We combined the side scan sonar with a sub-bottom profiler and also a device we called the micro profiler that could get the tops of little pipelines on the seabed. We patented a scheme to combine a side scan and sub-botton profiler with a magenetometer. But one of the biggest changes is the change to digital. The old machines used to use a mechanical graphic recorder with analog signal processing. It worked, but it had all sorts of problems, it was expensive to make, it was difficult to operate. And the transition progressed where the machines went from those mechanical recorders to thermal graphic recorders and eventually to computer displays. The display used to be on a color television, but nowadays you can put it on a laptop so you don’t have this big clunky mechanical recorder and you can easily record the data digitally so you can go back replay it and do other processing.

Another huge change is the area of navigation. Navigation has changed drastically since I started. When I started in the field we used to position the ship with transits, theodolights and hand-bearing compasses. I was involved in some of the first electronic positioning systems. I participated in a survey of the English Channel back 1964 where we used something called Decca HiFix to navigate the ship electronically. But then eventually global positioning came along so for very little money you can get a very precise navigation system, put it on a ship, and you can get the navigation data and combine it onto the sonar records. You can record, you can do survey lines, you can have the recorder plot the survey lines, where have you been, you can go back to a spot if you found something. So there’s huge changes in the use of combination of computers and navigation with the side scan.

There has also been a lot of work on the image processing. You improve the sonar data to expand and enhance the data, and also make the equipment easier to operate.

Outside of your own technology, what one technology do you believe has had the greatest impact on allowing humans to study the oceans?

MK: Whoa. It’s such a broad subject and I was involved with so many, and I feel proud that my own devices helped to open up the world of the ocean. We use the term ‘Make the Ocean Transparent.’ I think we made a difference. Nowadays many devices use our technology - the underwater vehicles – the human occupied submersibles and then the remote operated vehicles – and now there’s a transition going on to autonomous vehicles that you can send out without humans in them that have all sorts of advantages.

I’ve been involved for many years with Sea Grant. The Sea Grant program is also 50 years old this year. And I’ve been involved with it in various ways since it began in 1967, especially at MIT and the University of New Hampshire. A lot of the autonomous vehicle technology was developed at MIT. The company Bluefin [Robotics] got its start as spinoff from MIT Sea Grant, and so I think that is making a big difference in our abilities to do ocean exploration.

Are there any technologies in development now that you’re keeping an eye on or see as particularly exciting?

MK: I keep an eye out all the time. I’m retired, but I’m still fascinated by the ocean, the subject of exploring the ocean. The equipment we have, although I’m very proud of it and proud to have gotten a lot of things started. If you look at a magazine like yours, it seems every few pages there’s a side scan sonar image of a ship wreck or picture of something on the bottom. I’m proud of it, but I feel like there’s going to be breakthroughs where we can have more coverage, have better pictures, have pictures that you can take at high speed and that look more like aerial photographs and so I’m still waiting for breakthroughs in technology.

I’m involved in a lot of things where students are involved. I just came back from the MATE Program. I’m involved with the MATE ROV competition. We just had an international competition in Long Beach, Calif. The students come from all over the world, and they’re working on these vehicles – these underwater vehicles – I always have my eye out for kids who might be the next Jacques Cousteau or Bob Ballard or Ed Link or George Bass or Elisha Linder. I still think there are breakthroughs to be made that will improve this technology dramatically.

What do you consider to be your biggest success?

MK: In the ocean field: I did not invent side scan sonar. People often say that my old professor Edgerton invented side scan sonar or I invented side scan sonar. He did not, and I did not. But what I did was introduce to the world 50 years ago a commercial version that was affordable, that was rugged, that was reliable, that produced good results. And I really feel proud that it did change the world of ocean exploration.

In your career, what was the biggest challenge you faced, and how did you overcome it?

MK: There were so many. Working in the ocean isn’t easy! People often take it for granted, but making high technology equipment that works in the ocean, that can run 24 hours a day, and work in boats and remote parts of the world, and work in very deep water is very challenging. There are many challenges with electronics, with circuitry, with mechanical things, with cables, with connectors, with transducers, with encapsulation, and so many, many challenges. Still to this day, you don’t go to the library and pick up a book on how to build a sonar. There’s no such thing. So we had to develop a lot of these technologies. I certainly didn’t do it on my own. I had a lot of help. A lot of things, you can go to the library and get a book on how to make a garden – whatever – how to cook a meal. But there’s still a lot of technology to learn and develop, and a lot of it is still challenging.

I still love this field. I’m still very excited about it. I appreciated what folks like you do: keeping people informed about what’s new. It’s still a relatively specialized field, and to some extent it’s a small family, and so I feel very excited about it. I still feel that there’s tremendous potential to create, and find things of cultural importance, finding ancient things, finding bottom geology, finding things that create jobs, improving the environment, improving our abilities to look at sea life, to find fish and to study them and other environmental aspects. I still really like the field. So many fields are very mature, and I still feel in many ways work in the ocean is in its infancy. There’s stuff to be found, and I feel honored to be a part of that.

Frank Cobis has had a long and vibrant career in the subsea technology industry. Today he leads Klein Marine Systems as vice president and general manager. Here he delivers an update on the company, its offering and the technologies driving change.

Please tell me a bit about yourself, your career and how you came to Klein Marine Systems?

Frank Cobis: I’ve been in the marine technology industry basically my entire career; more than 30 years. I started in the early ’80s with a company that manufactures deep-water multibeam sonar systems, SeaBeam Instruments. I worked for SeaBeam through the early 2000s under several different ownerships. In this timeframe, both SeaBeam and Klein were acquired by L-3 Communications, and the two companies were merged based on their complementary technology and close proximity – we’re in New Hampshire and SeaBeam was in Massachusetts. So, officially I joined Klein in 2004 as the vice president of programs.

What is the size and scope to Klein Marine Systems today?

FC: Klein was acquired by Mitcham Industries January 1, 2016. Mitcham is a small, nimble, international company with deep commercial roots in the marine technology industry, and it was a welcome acquisition on the part of Klein as it allowed us to get back to our core values and refocus on the commercial side of the business. At that point in time, we also reengaged with Marty Klein, and we consider Marty to be an ambassador for our company.

What’s changed since January 2016?

FC: Like I said, the new ownership has allowed us to refocus on the core values of our business. These core values are the same values that Marty had when he started the business. It was all about delivering a high performance product, quality and providing excellent customer support. Our tagline, as you might have seen, is, “The difference is in the image,” and for us that resonates in everything we do. We’re not satisfied with our product performance until we have a side scan image that looks photographic.

What’s changed externally to our business is that the marketplace has become more complex and more competitive. This change has repositioned our product development toward common platforms and more modularity in our system design. This building block approach allows us to be more nimble and allows us to better perform in the current competitive environment.

For example?

FC: We recently released two new single beam products that we’re real excited about. The Klein 4900 and 4000 systems are based upon our very successful UUV-3500 sonar engine. Both products use our high performance data acquisition front-end and our new telemetry design. There’s modularity in the power interface and transmitter designs which we already have plans to use in our next product currently under development. From a software perspective, we have a single code base that allows us to build multiple versions of software for this family of products.

We can also build custom solutions using these modular components, and that’s another piece of the business we find very challenging. We have our standard product line, but we’ve also developed many custom designs to meet customer specific needs. We look forward to customers bringing their inquiries to us where they have a unique project with challenging requirements where they just can’t buy something off the shelf. Our goal is to work closely with these customers to develop custom configurations to satisfy their needs.

What market demands will drive the technology ahead in the next few years?

FC: The market expects continuous improvement. Our customers are constantly requiring us to produce products that provide better area coverage, better resolution and better system accuracy. We’re constantly taking advantage of technology advances that allow us to provide these kind of performance discriminators. Ease of use is a big thing, especially for entry level products where a customer wants to be able to pull it out of the box and connect the cables, flip the switch and immediately start using the system.

We just recently finished a SMART telemetry design, and I think we’re the first in the industry to offer this capability. The tow cable is typically a customer supplied piece of the overall system. You bring a side scan onto a ship, there’s already a winch on board, it’s got a cable on it. You want to run that sonar with that cable. So with this SMART telemetry design the system measures the electrical parameters of the interconnect between the topside equipment and tow fish – deck cables, slip ring and tow cable – and selects data rate and filter settings that minimize telemetry errors while maximizing data throughput. This results in continuous, high quality imaging over a broad variety of cable types and cable lengths. In the case of standard fixed rate telemetry systems, they simply stop transferring data when the cabling will not support their required data rate. This could be caused by excessive length, aged or degraded cable or poor electrical connections. With our SMART telemetry design, if the automated test of the system cabling results in an available data rate lower than that required for the higher bandwidth pulse types of the side scan system, the software readily adapts the user settings to those supported by the available data bandwidth, keeping the system available for use across a broad set of cable configurations. The bottom line is you always come back to shore with data.

We also have several new products under development which will provide game changing performance when released. It’s too early to talk about these developments, but we are very focused on bringing them to the market.

You mentioned earlier the focus on producing photo-quality imaging. Will you discuss some of the evolutions that have recently taken place in this area?

FC: Most of our new products are based on broadband technology which allows the image to have a much deeper, richer, tonal quality. Complementing this architecture is a number of signal and display processing improvements which further enhance the imagery.

Where do you see the greatest opportunities for growth?

FC: From our perspective, we recently developed a new high-end sonar, the Klein 5900. We’re seeing a lot of potential growth in the military market for this product. We still consider this a commercial system solution, but it fits well within a lot of military MCM applications. The interesting thing about the 5900 system as compared to some of the full-up true military systems is you can get 90 percent of the performance for less than 30 percent of the cost. So there’s a value proposition there and we’re finding that there are a lot of military customers that are very interested in this system and its performance.

Another area of growth is the vehicle market: ROVs, AUVs, USVs and special purpose platforms. This market is growing in leaps and bounds, and in this market our products are more a sensor payload than a system. These payloads need to be tightly integrated into the vehicle to achieve the desired performance. This is an area we’re really focused on because it’s a bit different; again, you’re a sensor versus a system. So you have to work very closely with the system integrator – typically the vehicle manufacturer – giving close attention to power, cooling, electrical/mechanical/acoustic interference and the software interface to insure optimal performance. This is a growing market and a market that we’re paying very, very close attention to.

(As published in the September 2017 edition of Marine Technology Reporter)

Read Klein's Side Scan Sonar, Then and Now in Pdf, Flash or Html5 edition of September 2017 Marine Technology

Other stories from September 2017 issue

Content

- Preview: GEO Week 2017 page: 10

- Digital Transformation of Port Operations page: 12

- New C-DRONE for Undisturbed Wave Spectrum Measurements page: 12

- Klein's Side Scan Sonar, Then and Now page: 16

- Interview: Woodson Ferreira, Aker Solutions, Brazil page: 18

- Smarter Ocean Robotics page: 30

- Machines Infused with AI that Fly, Swarm and Dive page: 34

- GeoSphere: Mapping-while-drilling Evolution page: 40

- Wind Energy: The Good News in Offshore page: 40

- Meet the CARTHE Drifter page: 44

- Research Vessels: The Fleet is In page: 50