ROV Roundup: Recent Tech Innovations

MTR highlights recent technological advances in the world of remotely operated underwater vehicles (ROV).

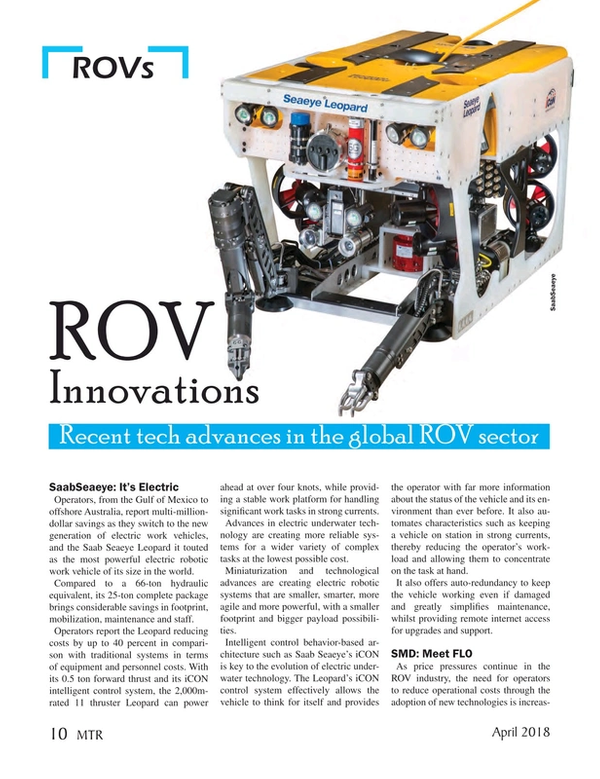

SaabSeaeye: It’s Electric

Operators, from the Gulf of Mexico to offshore Australia, report multi-million-dollar savings as they switch to the new generation of electric work vehicles, and the Saab Seaeye Leopard it touted as the most powerful electric robotic work vehicle of its size in the world.

Compared to a 66-ton hydraulic equivalent, its 25-ton complete package brings considerable savings in footprint, mobilization, maintenance and staff.

Operators report the Leopard reducing costs by up to 40 percent in comparison with traditional systems in terms of equipment and personnel costs. With its 0.5 ton forward thrust and its iCON intelligent control system, the 2,000m-rated 11 thruster Leopard can power ahead at over four knots, while providing a stable work platform for handling significant work tasks in strong currents.

Advances in electric underwater technology are creating more reliable systems for a wider variety of complex tasks at the lowest possible cost.

Miniaturization and technological advances are creating electric robotic systems that are smaller, smarter, more agile and more powerful, with a smaller footprint and bigger payload possibilities.

Intelligent control behavior-based architecture such as Saab Seaeye’s iCON is key to the evolution of electric underwater technology. The Leopard’s iCON control system effectively allows the vehicle to think for itself and provides the operator with far more information about the status of the vehicle and its environment than ever before. It also automates characteristics such as keeping a vehicle on station in strong currents, thereby reducing the operator’s workload and allowing them to concentrate on the task at hand.

It also offers auto-redundancy to keep the vehicle working even if damaged and greatly simplifies maintenance, whilst providing remote internet access for upgrades and support.

SMD: Meet FLO

As price pressures continue in the ROV industry, the need for operators to reduce operational costs through the adoption of new technologies is increasingly apparent. For areas such as seabed mapping and pipeline inspection, where traditional work class ROV systems remain the preferred choice, SMD has recognized the limitations of the current technology available and developed FLO, a new high-speed survey and inspection ROV system. Traditionally, standard work class ROVs have speed limitations due to their size, weight and hydrodynamics. They can also be unsteady operating at higher speeds.

SMD engineered FLO, a high-speed variant based on proven SMD ROV fleet technology, to perform tasks faster and more efficiently. The new system has a top speed of 6 knots and the ability to hold position in currents up to 4 knots from any direction. FLO also boasts 50% faster survey times compared to conventional work class ROVs and is capable of significantly extending the operational window in areas where high currents are prevalent, especially within the renewables sector.

From concept to manufacture, the new high-speed ROV by SMD, has been designed around the latest sensor payloads it would be tasked to carry in order to perform offshore, while also providing the most stable and acoustically quiet platform possible to gather quality survey data.

In order to provide this level of performance, FLO uses SMD’s advanced ROV drivetrain technology in a low profile hydrodynamic package less than half the height and half the weight of a typical Work Class ROV. Coupled with eight open water vectored thrusters and SMD’s advanced ROV control automation, FLO is able to accurately navigate and remain stable at high speeds while close to the seabed.

FLO can also be operated in free swimming mode for shallow water and uses a tether management system (TMS) in deeper water. Although travelling at high speed creates drag on the ROV umbilical, in water depths of 500m in free swimming mode, FLO has the power to achieve speeds greater than 4 knots.

When using a TMS for deep water operation, the umbilical drag is transferred to the surface vessel allowing the high speed ROV a high degree of maneuverability on a short 50m tether. This mode allows a calculated maximum speed of 5.6 Knots in depths over 2,000m.

FLO Specs

Length: 3.5m

Width: 1.9m

Height: 1m

Weight: 2.5te

Depth: 2,000msw

Power: 150kW

Max speed (no tether): 6.1 knots

Payload: 200kg

FET’s New XLe Spirit

Forum Energy Technologies launched a new electric remotely operated vehicle (EROV) range. Designed and manufactured in-house at Forum’s Kirkbymoorside Yorkshire facility, the XLe Spirit is the company’s first of a new generation of electric ROVs.

The vehicle is the smallest in the new range but is powerful enough to perform subsea maintenance and repair work with the use of its optional electric or hydraulic five function manipulator arm. The vehicle’s self-regulating power feature compensates for tether losses ensuring a constant and stable power delivery to the vehicle regardless of tether length.

It uses the same advanced Forum Integrated Control Engine (ICE++) found in larger work-class and trencher vehicles in the Forum product range. This provides a wide range of auto-pilot and pilot assist modes when appropriate sensors are fitted.

The control electronics pod fitted to all Forum XLe electric vehicles is designed to enable superior connectivity and expansion capabilities when compared with other ROVs on the market. Ethernet interfacing allows for seamless integration with other industry sensors using common IP architecture and ease of remote data transfer.

Blue Robotics: Retrofit Kit

Blue Robotics released a retrofit kit which provides the components needed to upgrade to the BlueROV2 Heavy Configuration. The upgrade allows the ROV to have four vertical thrusters, external thruster guards, and additional buoyancy. The additions enable the vehicle to gain 6 degree-of-freedom control and active stabilization in roll and pitch, making the BlueROV2 Heavy the most stable but maneuverable mini ROV on the market. Since this kit has been in the works since before the BlueROV2 was launched, every ROV in the wild already has the necessary mounting holes for the upgrade. Kits are $599 and are shipping with a two week lead time.

(As published in the April 2018 edition of Marine Technology Reporter)

Read ROV Roundup: Recent Tech Innovations in Pdf, Flash or Html5 edition of April 2018 Marine Technology

Other stories from April 2018 issue

Content

- Shell Ocean Discovery XPrize Field Pared to 9 page: 6

- ROV Roundup: Recent Tech Innovations page: 10

- Top Five Trends in Offshore Wind page: 14

- Interview: David Millar, Fugro page: 16

- MG3 & Satellite Derived Bathymetry page: 20

- Ocean Autonomy: Norway to the Fore page: 24

- A Record-setting Journey to the Atacama Trench page: 34