Page 47: of Marine Technology Magazine (January 2020)

Read this page in Pdf, Flash or Html5 edition of January 2020 Marine Technology Magazine

tools may be key, for some operators, to are structurally similar. perfect IMR Swiss Army Knife. “We’ve securing inspections and then certi? ca- “We made climbing our trade,” Sch- never used it. It was too good. Too big. tions of platform integrity. jetne says. “We saw that there was a Too perfect. Too heavy to install. We need for working just below the surface. learned a lot. We made smaller tools.”

Splash zone climber Divers couldn’t work there. No one So, a two-meter-long arm for inspec-

Judging by a DNV GL study, the surf could work in the splash zone.” Work tion and cleaning was devised. It can is a neglected area of safety: “In areas between 2007 to 2019 created a line of inspect grout work on wind installations with harsh environments, such as in the ready-to-go access tools, with ? ve or six or clear marine fouling on aquaculture

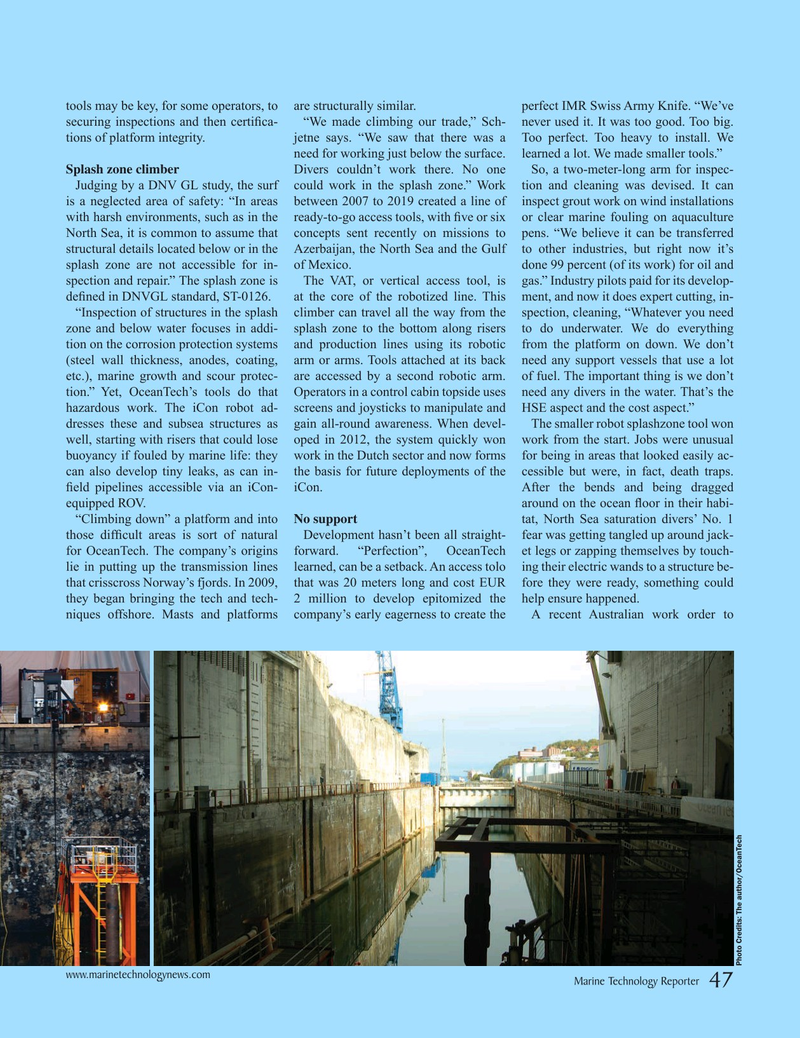

North Sea, it is common to assume that concepts sent recently on missions to pens. “We believe it can be transferred structural details located below or in the Azerbaijan, the North Sea and the Gulf to other industries, but right now it’s splash zone are not accessible for in- of Mexico. done 99 percent (of its work) for oil and spection and repair.” The splash zone is The VAT, or vertical access tool, is gas.” Industry pilots paid for its develop- de? ned in DNVGL standard, ST-0126. at the core of the robotized line. This ment, and now it does expert cutting, in- “Inspection of structures in the splash climber can travel all the way from the spection, cleaning, “Whatever you need zone and below water focuses in addi- splash zone to the bottom along risers to do underwater. We do everything tion on the corrosion protection systems and production lines using its robotic from the platform on down. We don’t (steel wall thickness, anodes, coating, arm or arms. Tools attached at its back need any support vessels that use a lot etc.), marine growth and scour protec- are accessed by a second robotic arm. of fuel. The important thing is we don’t tion.” Yet, OceanTech’s tools do that Operators in a control cabin topside uses need any divers in the water. That’s the hazardous work. The iCon robot ad- screens and joysticks to manipulate and HSE aspect and the cost aspect.” dresses these and subsea structures as gain all-round awareness. When devel- The smaller robot splashzone tool won well, starting with risers that could lose oped in 2012, the system quickly won work from the start. Jobs were unusual buoyancy if fouled by marine life: they work in the Dutch sector and now forms for being in areas that looked easily ac- can also develop tiny leaks, as can in- the basis for future deployments of the cessible but were, in fact, death traps. ? eld pipelines accessible via an iCon- iCon. After the bends and being dragged equipped ROV. around on the ocean ? oor in their habi- “Climbing down” a platform and into No support tat, North Sea saturation divers’ No. 1 those dif? cult areas is sort of natural Development hasn’t been all straight- fear was getting tangled up around jack- for OceanTech. The company’s origins forward. “Perfection”, OceanTech et legs or zapping themselves by touch- lie in putting up the transmission lines learned, can be a setback. An access tolo ing their electric wands to a structure be- that crisscross Norway’s fjords. In 2009, that was 20 meters long and cost EUR fore they were ready, something could they began bringing the tech and tech- 2 million to develop epitomized the help ensure happened. niques offshore. Masts and platforms company’s early eagerness to create the A recent Australian work order to

Photo Credits: The author/OceanTech www.marinetechnologynews.com

Marine Technology Reporter 47

MTR #1 (34-49).indd 47 1/16/2020 11:47:51 AM

46

46

48

48