Page 48: of Marine Technology Magazine (January 2020)

Read this page in Pdf, Flash or Html5 edition of January 2020 Marine Technology Magazine

Autonomous Navigation & Vehicle Tooling

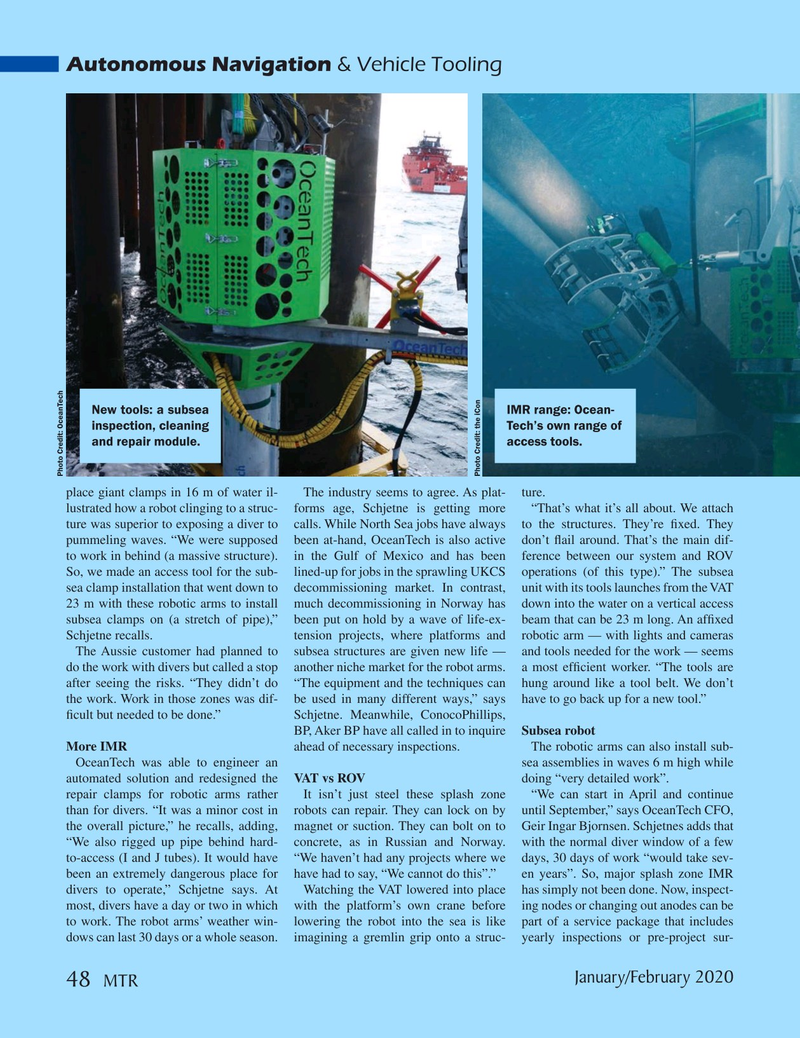

New tools: a subsea IMR range: Ocean- inspection, cleaning Tech’s own range of and repair module. access tools.

Photo Credit: OceanTech

Photo Credit: the iCon place giant clamps in 16 m of water il- The industry seems to agree. As plat- ture. lustrated how a robot clinging to a struc- forms age, Schjetne is getting more “That’s what it’s all about. We attach ture was superior to exposing a diver to calls. While North Sea jobs have always to the structures. They’re ? xed. They pummeling waves. “We were supposed been at-hand, OceanTech is also active don’t ? ail around. That’s the main dif- to work in behind (a massive structure). in the Gulf of Mexico and has been ference between our system and ROV

So, we made an access tool for the sub- lined-up for jobs in the sprawling UKCS operations (of this type).” The subsea sea clamp installation that went down to decommissioning market. In contrast, unit with its tools launches from the VAT 23 m with these robotic arms to install much decommissioning in Norway has down into the water on a vertical access subsea clamps on (a stretch of pipe),” been put on hold by a wave of life-ex- beam that can be 23 m long. An af? xed

Schjetne recalls. tension projects, where platforms and robotic arm — with lights and cameras

The Aussie customer had planned to subsea structures are given new life — and tools needed for the work — seems do the work with divers but called a stop another niche market for the robot arms. a most ef? cient worker. “The tools are after seeing the risks. “They didn’t do “The equipment and the techniques can hung around like a tool belt. We don’t the work. Work in those zones was dif- be used in many different ways,” says have to go back up for a new tool.” ? cult but needed to be done.” Schjetne. Meanwhile, ConocoPhillips,

BP, Aker BP have all called in to inquire Subsea robot

More IMR ahead of necessary inspections. The robotic arms can also install sub-

OceanTech was able to engineer an sea assemblies in waves 6 m high while automated solution and redesigned the VAT vs ROV doing “very detailed work”. repair clamps for robotic arms rather It isn’t just steel these splash zone “We can start in April and continue than for divers. “It was a minor cost in robots can repair. They can lock on by until September,” says OceanTech CFO, the overall picture,” he recalls, adding, magnet or suction. They can bolt on to Geir Ingar Bjornsen. Schjetnes adds that “We also rigged up pipe behind hard- concrete, as in Russian and Norway. with the normal diver window of a few to-access (I and J tubes). It would have “We haven’t had any projects where we days, 30 days of work “would take sev- been an extremely dangerous place for have had to say, “We cannot do this”.” en years”. So, major splash zone IMR divers to operate,” Schjetne says. At Watching the VAT lowered into place has simply not been done. Now, inspect- most, divers have a day or two in which with the platform’s own crane before ing nodes or changing out anodes can be to work. The robot arms’ weather win- lowering the robot into the sea is like part of a service package that includes dows can last 30 days or a whole season. imagining a gremlin grip onto a struc- yearly inspections or pre-project sur-

January/February 2020 48

MTR

MTR #1 (34-49).indd 48 1/21/2020 4:49:59 PM

47

47

49

49