Page 36: of Marine Technology Magazine (April 2020)

Read this page in Pdf, Flash or Html5 edition of April 2020 Marine Technology Magazine

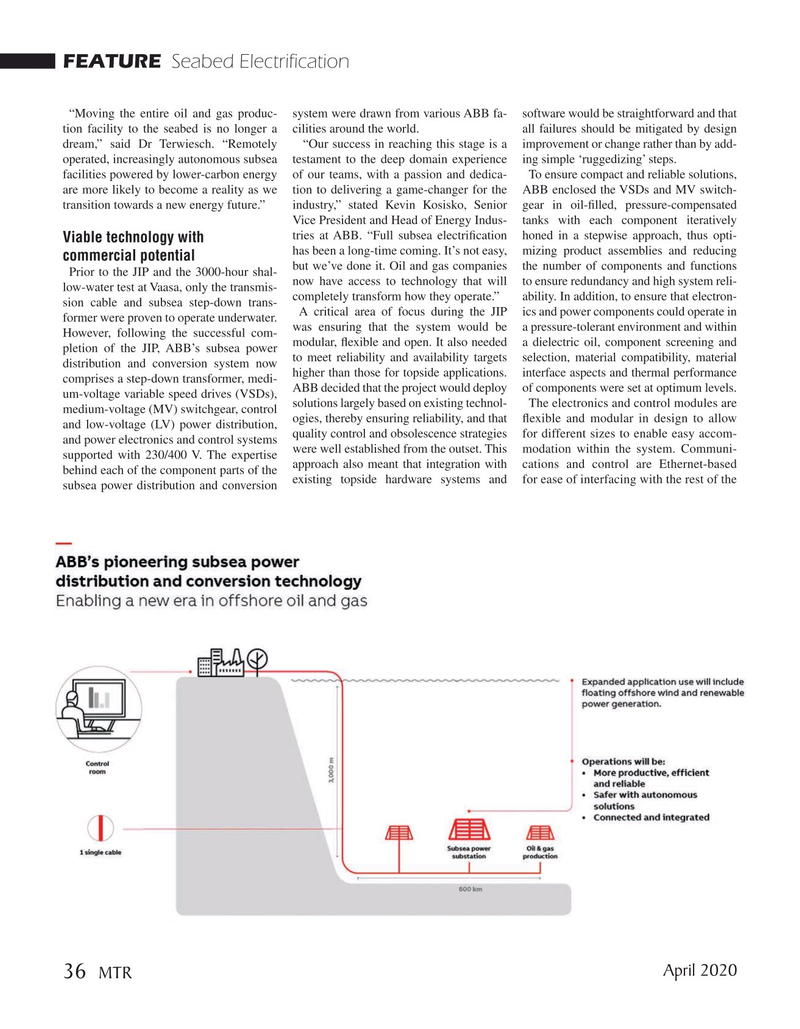

FEATURE Seabed Electrification “Moving the entire oil and gas produc- system were drawn from various ABB fa- software would be straightforward and that tion facility to the seabed is no longer a cilities around the world. all failures should be mitigated by design dream,” said Dr Terwiesch. “Remotely “Our success in reaching this stage is a improvement or change rather than by add- operated, increasingly autonomous subsea testament to the deep domain experience ing simple ‘ruggedizing’ steps.

facilities powered by lower-carbon energy of our teams, with a passion and dedica- To ensure compact and reliable solutions, are more likely to become a reality as we tion to delivering a game-changer for the ABB enclosed the VSDs and MV switch- transition towards a new energy future.” industry,” stated Kevin Kosisko, Senior gear in oil-flled, pressure-compensated

Vice President and Head of Energy Indus- tanks with each component iteratively tries at ABB. “Full subsea electrifcation honed in a stepwise approach, thus opti-

Viable technology with has been a long-time coming. It’s not easy, mizing product assemblies and reducing commercial potential but we’ve done it. Oil and gas companies the number of components and functions

Prior to the JIP and the 3000-hour shal- now have access to technology that will to ensure redundancy and high system reli- low-water test at Vaasa, only the transmis- completely transform how they operate.” ability. In addition, to ensure that electron- sion cable and subsea step-down trans-

A critical area of focus during the JIP ics and power components could operate in former were proven to operate underwater. was ensuring that the system would be a pressure-tolerant environment and within

However, following the successful com- pletion of the JIP, ABB’s subsea power modular, fexible and open. It also needed a dielectric oil, component screening and distribution and conversion system now to meet reliability and availability targets selection, material compatibility, material higher than those for topside applications. interface aspects and thermal performance comprises a step-down transformer, medi-

ABB decided that the project would deploy of components were set at optimum levels.

um-voltage variable speed drives (VSDs), solutions largely based on existing technol- The electronics and control modules are medium-voltage (MV) switchgear, control and low-voltage (LV) power distribution, ogies, thereby ensuring reliability, and that fexible and modular in design to allow quality control and obsolescence strategies for different sizes to enable easy accom- and power electronics and control systems supported with 230/400 V. The expertise were well established from the outset. This modation within the system. Communi- approach also meant that integration with cations and control are Ethernet-based behind each of the component parts of the subsea power distribution and conversion existing topside hardware systems and for ease of interfacing with the rest of the April 2020 36

MTR

35

35

37

37