Page 40: of Marine Technology Magazine (June 2020)

Read this page in Pdf, Flash or Html5 edition of June 2020 Marine Technology Magazine

FEATURE Hydrographic Survey

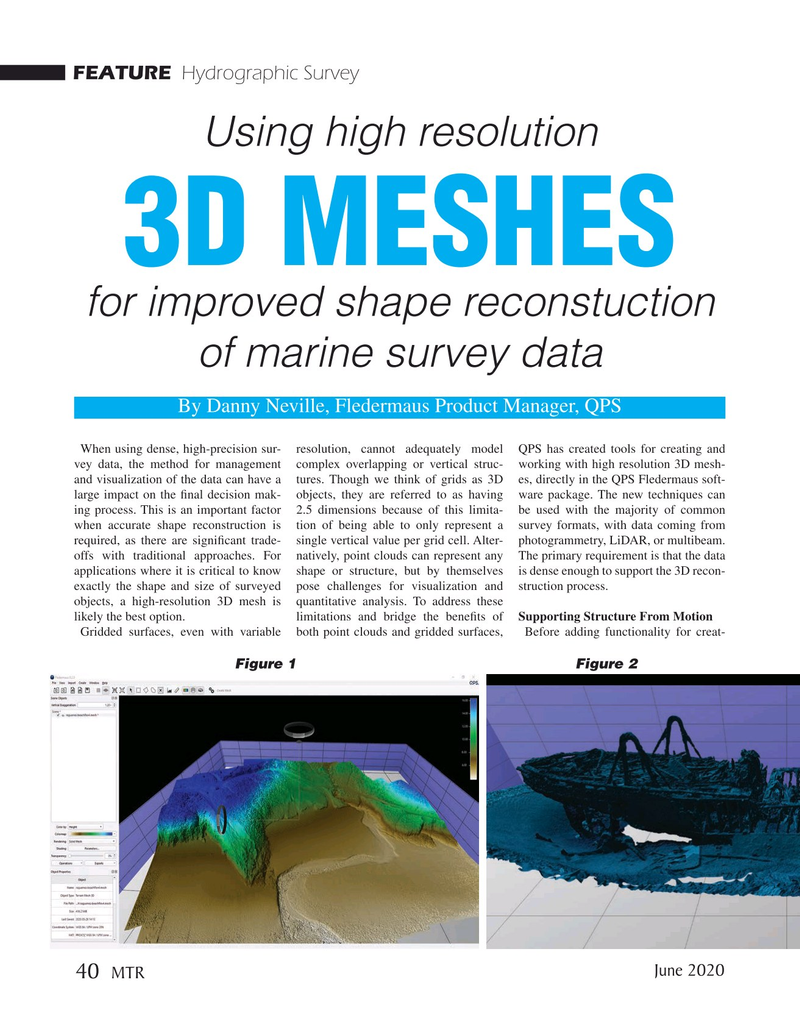

Using high resolution 3D Meshes for improved shape reconstuction of marine survey data

By Danny Neville, Fledermaus Product Manager, QPS

When using dense, high-precision sur- resolution, cannot adequately model QPS has created tools for creating and vey data, the method for management complex overlapping or vertical struc- working with high resolution 3D mesh- and visualization of the data can have a tures. Though we think of grids as 3D es, directly in the QPS Fledermaus soft- large impact on the fnal decision mak- objects, they are referred to as having ware package. The new techniques can ing process. This is an important factor 2.5 dimensions because of this limita- be used with the majority of common when accurate shape reconstruction is tion of being able to only represent a survey formats, with data coming from required, as there are signifcant trade- single vertical value per grid cell. Alter- photogrammetry, LiDAR, or multibeam. offs with traditional approaches. For natively, point clouds can represent any The primary requirement is that the data applications where it is critical to know shape or structure, but by themselves is dense enough to support the 3D recon- exactly the shape and size of surveyed pose challenges for visualization and struction process. objects, a high-resolution 3D mesh is quantitative analysis. To address these likely the best option. limitations and bridge the benefts of Supporting Structure From Motion

Gridded surfaces, even with variable both point clouds and gridded surfaces, Before adding functionality for creat-

Figure 1 Figure 2

June 2020 40

MTR

39

39

41

41