Page 34: of Marine Technology Magazine (January 2023)

Read this page in Pdf, Flash or Html5 edition of January 2023 Marine Technology Magazine

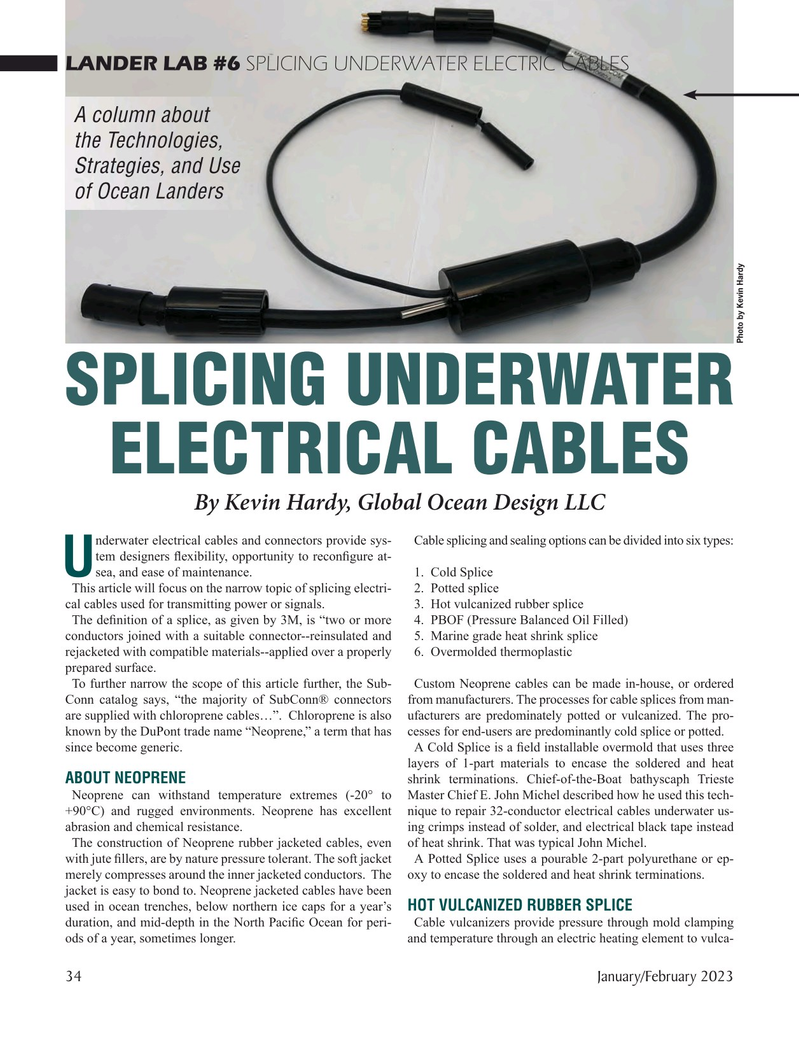

LANDER LAB #6 SPLICING UNDERWATER ELECTRIC CABLES

A column about the Technologies,

Strategies, and Use of Ocean Landers

Photo by Kevin Hardy

SPLICING UNDERWATER

ELECTRICAL CABLES

By Kevin Hardy, Global Ocean Design LLC nderwater electrical cables and connectors provide sys- Cable splicing and sealing options can be divided into six types: tem designers ? exibility, opportunity to recon? gure at-

Usea, and ease of maintenance. 1. Cold Splice

This article will focus on the narrow topic of splicing electri- 2. Potted splice cal cables used for transmitting power or signals. 3. Hot vulcanized rubber splice

The de? nition of a splice, as given by 3M, is “two or more 4. PBOF (Pressure Balanced Oil Filled) conductors joined with a suitable connector--reinsulated and 5. Marine grade heat shrink splice rejacketed with compatible materials--applied over a properly 6. Overmolded thermoplastic prepared surface.

To further narrow the scope of this article further, the Sub- Custom Neoprene cables can be made in-house, or ordered

Conn catalog says, “the majority of SubConn® connectors from manufacturers. The processes for cable splices from man- are supplied with chloroprene cables…”. Chloroprene is also ufacturers are predominately potted or vulcanized. The pro- known by the DuPont trade name “Neoprene,” a term that has cesses for end-users are predominantly cold splice or potted.

since become generic. A Cold Splice is a ? eld installable overmold that uses three layers of 1-part materials to encase the soldered and heat

ABOUT NEOPRENE shrink terminations. Chief-of-the-Boat bathyscaph Trieste

Neoprene can withstand temperature extremes (-20° to Master Chief E. John Michel described how he used this tech- +90°C) and rugged environments. Neoprene has excellent nique to repair 32-conductor electrical cables underwater us- abrasion and chemical resistance. ing crimps instead of solder, and electrical black tape instead

The construction of Neoprene rubber jacketed cables, even of heat shrink. That was typical John Michel.

with jute ? llers, are by nature pressure tolerant. The soft jacket A Potted Splice uses a pourable 2-part polyurethane or ep- merely compresses around the inner jacketed conductors. The oxy to encase the soldered and heat shrink terminations.

jacket is easy to bond to. Neoprene jacketed cables have been used in ocean trenches, below northern ice caps for a year’s HOT VULCANIZED RUBBER SPLICE duration, and mid-depth in the North Paci? c Ocean for peri- Cable vulcanizers provide pressure through mold clamping ods of a year, sometimes longer. and temperature through an electric heating element to vulca- 34 January/February 2023

MTR #1 (34-47).indd 34 1/23/2023 3:15:29 PM

33

33

35

35