Page 8: of Maritime Reporter Magazine (March 15, 1969)

Read this page in Pdf, Flash or Html5 edition of March 15, 1969 Maritime Reporter Magazine

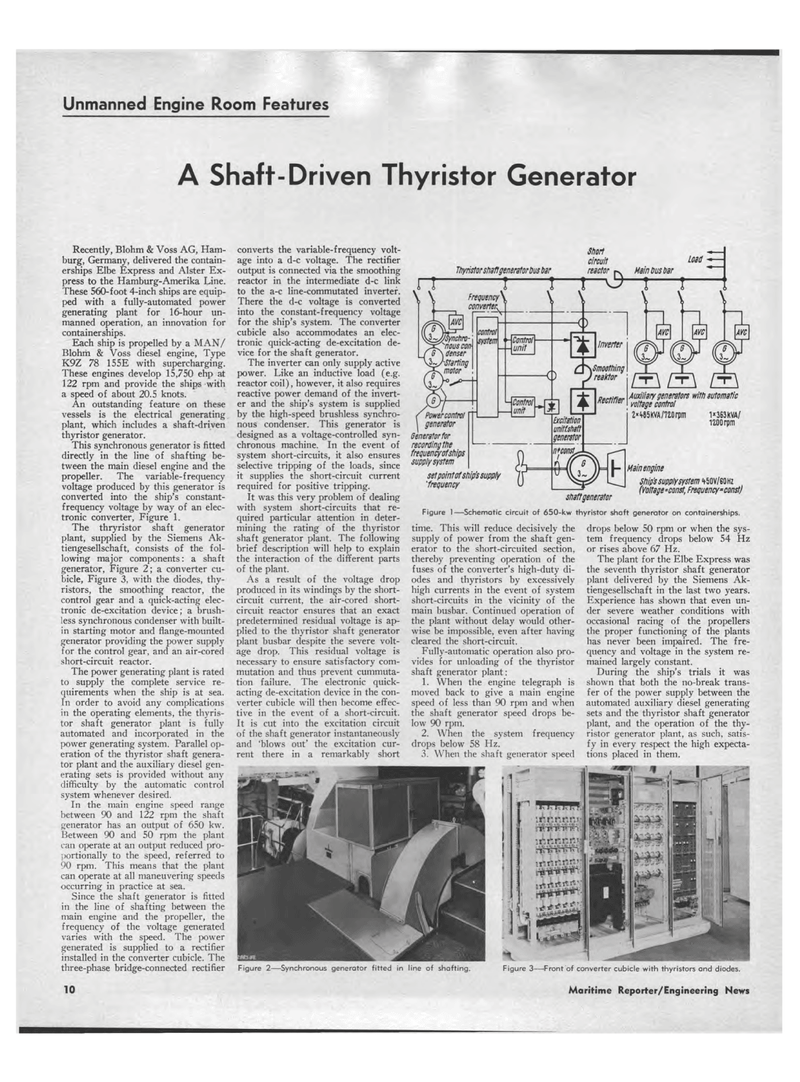

Unmanned Engine Room Features A Shaft-Driven Thyristor Generator Recently, Blohm & Voss AG, Ham-burg, Germany, delivered the contain-erships Elbe Express and Alster Ex-press to the Hamburg-Amerika Line. These 560-foot 4-inch ships are equip-ped with a fully-automated power generating plant for 16-hour un-manned operation, an innovation for containerships. Each ship is propelled by a MAN/ Blohm & Voss diesel engine, Type K9Z 78 155E with supercharging. These engines develop 15,750 ehp at 122 rpm and provide the ships with a speed of about 20.5 knots. An outstanding feature on these vessels is the electrical generating plant, which includes a shaft-driven thyristor generator. This synchronous generator is fitted directly in the line of shafting be-tween the main diesel engine and the propeller. The variable-frequency voltage produced by this generator is converted into the ship's constant-frequency voltage by way of an elec-tronic converter, Figure 1. The thryristor shaft generator plant, supplied by the Siemens Ak-tiengesellschaft, consists of the fol-lowing major components: a shaft generator, Figure 2; a converter cu-bicle, Figure 3, with the diodes, thy-ristors, the smoothing reactor, the control gear and a quick-acting elec-tronic de-excitation device; a brush-less synchronous condenser with built-in starting motor and flange-mounted generator providing the power supply for the control gear, and an air-cored short-circuit reactor. The power generating plant is rated to supply the complete service re-quirements when the ship is at sea. In order to avoid any complications in the operating elements, the thyris-tor shaft generator plant is fully automated and incorporated in the power generating system. Parallel op-eration of the thyristor shaft genera-tor plant and the auxiliary diesel gen-erating sets is provided without any difficulty by the automatic control system whenever desired. In the main engine speed range between 90 and 122 rpm the shaft generator has an output of 650 kw. Between 90 and 50 rpm the plant can operate at an output reduced pro-portionally to the speed, referred to 90 rpm. This means that the plant can operate at all maneuvering speeds occurring in practice at sea. Since the shaft generator is fitted in the line of shafting between the main engine and the propeller, the frequency of the voltage generated varies with the speed. The power generated is supplied to a rectifier installed in the converter cubicle. The three-phase bridge-connected rectifier converts the variable-frequency volt-age into a d-c voltage. The rectifier output is connected via the smoothing reactor in the intermediate d-c link to the a-c line-commutated inverter. There the d-c voltage is converted into the constant-frequency voltage for the ship's system. The converter cubicle also accommodates an elec-tronic quick-acting de-excitation de-vice for the shaft generator. The inverter can only supply active power. Like an inductive load (e.g. reactor coil), however, it also requires reactive power demand of the invert-er and the ship's system is supplied by the high-speed brushless synchro-nous condenser. This generator is designed as a voltage-controlled syn-chronous machine. In the event of system short-circuits, it also ensures selective tripping of the loads, since it supplies the short-circuit current required for positive tripping. It was this very problem of dealing with system short-circuits that re-quired particular attention in deter-mining the rating of the thyristor shaft generator plant. The following brief description will help to explain the interaction of the different parts of the plant. As a result of the voltage drop produced in its windings by the short-circuit current, the air-cored short-circuit reactor ensures that an exact predetermined residual voltage is ap-plied to the thyristor shaft generator plant busbar despite the severe volt-age drop. This residual voltage is necessary to ensure satisfactory com-mutation and thus prevent cummuta-tion failure. The electronic quick-acting de-excitation device in the con-verter cubicle will then become effec-tive in the event of a short-circuit. It is cut into the excitation circuit of the shaft generator instantaneously and 'blows out' the excitation cur-rent there in a remarkably short Thyristor shaft generator bus bar t r \ Short circuit reactor rv Loan Main bus bar "1 t Control unit -v 1 Control unit % inverter Powercontrol generator Generator for recording the frequency of ships supply system set point of ship's supply 'frequency . £_i \ Smoothing -Q) J reaktor D.Mir,** Auxiliary generators with automatic nectmer voltage controi Z»W5KVA/7Z0rpm 1*363kVA/ 1200 rpm Mainengine Ship's supply system

7

7

9

9