Marystown Shipyard Building 225-Foot Deutz-Powered Tug/Supply Vessel

During the past year, Marystown Shipyard Limited in Newfoundland, Canada, has been developing an all-purpose anchor-handling/ tug/supply vessel design designated the M68 (LOA is 68.48 meters), capable of being fitted out with a number of options to suit almost any requirements for the various charter requirements worldwide.

The Marystown board of directors recently decided, after investigating worldwide supply ship requirements, to build one of these vessels for its own account, with the view to obtaining an owner before completion. Designated Hull 37, the vessel will be built to Lloyd's Register of Shipping classification + 100A1, Offshore Tug/Supply Ship, Ice Class 3, Deck Cargo (5 tons per square meter), +LMS, UMS, Unrestricted Service, Oil Recovery.

Hull 37 will have an overall length of 224.67 feet, beam of 49.21 feet, depth to main deck of 23.79 feet, and design draft of 18 feet. The vessel will be capable of discharging potable water, drill water, fuel oil, liquid mud, and two types of bulk cargo simultaneously to the highest existing drilling platform, and will also be capable of transhipping reclaimed oil in emergency spill conditions.

The vessel will be powered entirely by four Deutz diesel engines in a unique "father and son" installation with a total of 12,860 bhp at 900 rpm. The propulsion plant comprises two Deutz SBV 16M 628 engines, each with an output of 4,150 bhp at 900 rpm, and two SBV 9M 628 engines, each producing 2,280 bhp at 900 rpm. These will drive two lips controllable-pitch propellers in fixed nozzles at 180 rpm, via two twin-input, single-output reduction gearboxes, each rated for 6,430 bhp. Each gearbox will be provided with two power take-offs, one to drive the 1,400-kva alternator and one to serve future installation of a 2,400-hp fire-fighting pump.

The entire Deutz propulsion package is arranged to provide maximum fuel efficiency, with ideal top-end power potential. One Ulstein 800-hp bow thruster and one 600-hp stern thruster will be installed.

Deck machinery will include one heavy-duty, fully enclosed, hydraulic anchor-handling/towing winch with a maximum pull of 300 tons and static rating of 350 tons. Other deck gear comprises twin cable lifters, two 12-ton tugger winches, two 10-ton capstans, two double-drum wire storage reels, one set of towing pins, and one set of anchor-handling tongs.

Navigation and communications systems will include: Simrad 100 automatic direction finder and ED161 navigation sounder; JRC speed log type JLN203, and JMA 510 and -JMA 630 radars; two Sailor RT 144C VHF radiotelephone; two CMC DN15 portable VHF radios; one MCS 9000 satellite communications system; and a Skanti watch receiver. Other equipment will include gyrocompass with autopilot, portable joystick, emergency locator/ transmitter, and crewcall/talkback system.

Accommodations will be provided for six officers and six crew, all in single cabins, along with space for 12 supernumeraries. The accommodations will be fully air conditioned and designed for electric heating.

Marystown Shipyard management is very excited about the potential for this new vessel of its own design, and is confident that a buyer will be found before the vessel is completed in the fall of 1985.

Read Marystown Shipyard Building 225-Foot Deutz-Powered Tug/Supply Vessel in Pdf, Flash or Html5 edition of January 1985 Maritime Reporter

Other stories from January 1985 issue

Content

- Call For Papers Issued By SNAME New England For Computer Symposium page: 4

- Newman's Revises Catalog On NEWCO Cast Steel/ Pressure Seal Valves page: 5

- Couch Named President Of Matson Navigation— Wasacz President Of A&B page: 5

- SecNav Lehman Announces Contract Awards Totaling Almost $2 Billion page: 5

- Perkins Joins Seaward International As Senior Sales Engineer page: 6

- Hyde Names Two New Vice Presidents page: 6

- Another Fast Delaware Pilots Boat Delivered By Gladding-Hearn Yard page: 6

- Shaft Coupling Saves Time And Money For Northwest Boatbuilder page: 7

- Hyundai To Build Four Rigs For ODECO At Total Cost Of $260 Million page: 7

- RDI Announces $15-Million Agreement With China For Electronic Shipping Safety Systems page: 7

- 1985 A YEAR OF CHANGE AND CHALLENGE page: 8

- Newport News Shipbuilding Delivers Attack Submarine 'Olympia' page: 8

- Fifth Generation Of Family Named To Executive Posts At Hughes Companies page: 8

- Butterworth Announces A New SCAMP Underwater Hull Cleaning Station page: 8

- New Chief Seattle Fireboat Provides High-Speed Response page: 10

- New York Port Engineers' Society Tours MarineSafety Simulators page: 11

- Todd Awarded $30 Million By Navy To Modify First Aviation Support Vessel page: 11

- Armco Offers Brochure On Bigger And Better Aquamet Boat Shafting page: 12

- Recent Order For Two Schottel Thruster Units A First In U.S. Market page: 13

- Weld Fittings Available From Cajon Company page: 13

- Marystown Shipyard Building 225-Foot Deutz-Powered Tug/Supply Vessel page: 14

- COMPUTERIZED VESSEL MANAGEMENT SYSTEMS page: 14

- BIW Will Get $383.6-Million Navy Contract To Build Two Aegis CG-47 Cruisers page: 15

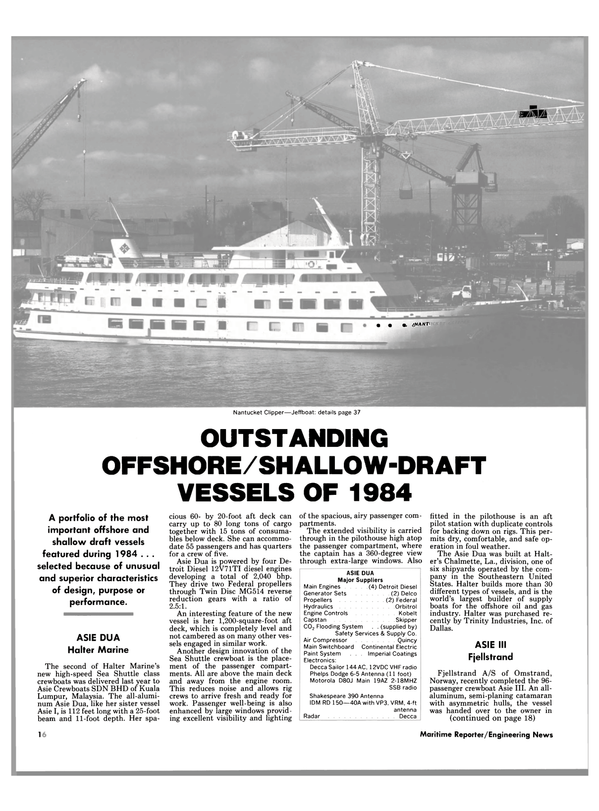

- OUTSTANDING OFFSHORE/SHALLOW-DRAFT VESSELS OF 1984 page: 16

- Marconi Introduces The New Oceanray SAT-COM page: 22

- Ingram Purchases Assets Of Ohio Barge Line And Mon-Valley Transportation page: 22

- Bay-Houston Towing Offers 'Port Reference Handbook' For Six Gulf Ports page: 23

- Eisert Named To Head General Electric's New Navy Programs Section page: 26

- Daewoo To Build Tanker For Norwegian Company For $40 Million page: 26

- Tracor Marine Awarded $2.5-Million MSC Contract To Operate Research Ship page: 28

- Navy Awards Bell Aerospace Textron $27.3-Million Contract For New Minesweeper Hunter page: 28

- Gerard M. McAllister 1910-1984 page: 29

- Diesel Engine Manufacturers Continue To Improve The Fuel Efficiency Of Their Engines page: 30

- KHD Introduces Two Systems For Worldwide Engine Monitoring Via Satellite Communications page: 45

- Sea Data Corporation Introduces Deep Sea Instrumentation Cable page: 46

- Kastalon Offers New Brochure On Polyurethane Crane Bumpers page: 47

- Goodway Offers New Catalog On Tube Cleaning Systems And Pressure Washers page: 47

- Armco And Oerlikon Sign Joint Manufacturing/ Marketing Agreement page: 48

- Carroll And Tomlin Named Vice Presidents At National Marine's Shipyard Division page: 49

- Puroflow Marine Introduces New Integrated Power-Line Protection System page: 53

- Navy's New Double-Deck Pier To Be Fitted With Sea Guard Fenders page: 53

- Rockwell Offers Brochure On Autonetics Division's Products And Capabilities page: 59

- New Quick-Connects Introduced By Crawford Fitting Co. page: 59