Page 139: of Maritime Reporter Magazine (September 1993)

Read this page in Pdf, Flash or Html5 edition of September 1993 Maritime Reporter Magazine

Cruise Ship And Ferry Costs In The 90s

The Economic Impact Of Increased Safety Demand

The cruise industry, and all vessels carrying fare paying passengers, faced with unprec- edented rising costs and slimmer margins, is entering a very radical and expensive phase in its development as it faces up to new safety and pollution control measures, higher insurance premiums, increasingly costly unilateral U.S. legislation and other cost pressures.

As in all other sectors of the shipping indus- try, the cruise/ferry operator must effectively control costs to survive.

Despite the recent profitability of most cruise operators, many markets are currently near saturation point with substantial discounting becoming the norm. The escalation of costs is inevitable and, therefore, an accurate under- standing of the current and future cost struc- ture of the industry is essential, with targeting, costing and pricing policy crucial to success.

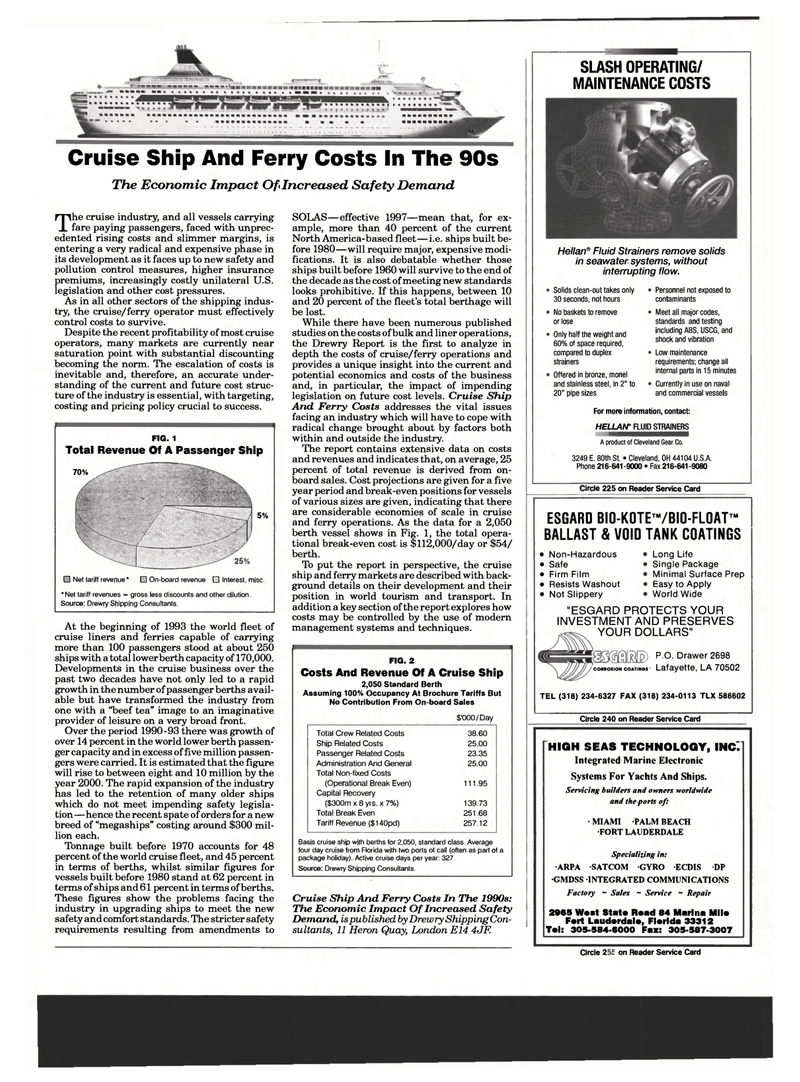

FIG. 1

Total Revenue Of A Passenger Ship 70% 5%

B Net tariff revenue * E3 On-board revenue E3 Interest, misc. *Net tariff revenues = gross less discounts and other dilution.

Source: Drewry Shipping Consultants.

At the beginning of 1993 the world fleet of cruise liners and ferries capable of carrying more than 100 passengers stood at about 250 ships with a total lower berth capacity of 170,000.

Developments in the cruise business over the past two decades have not only led to a rapid growth in the number of passenger berths avail- able but have transformed the industry from one with a "beef tea" image to an imaginative provider of leisure on a very broad front.

Over the period 1990-93 there was growth of over 14 percent in the world lower berth passen- ger capacity and in excess of five million passen- gers were carried. It is estimated that the figure will rise to between eight and 10 million by the year 2000. The rapid expansion of the industry has led to the retention of many older ships which do not meet impending safety legisla- tion—hence the recent spate of orders for a new breed of "megaships" costing around $300 mil- lion each.

Tonnage built before 1970 accounts for 48 percent of the world cruise fleet, and 45 percent in terms of berths, whilst similar figures for vessels built before 1980 stand at 62 percent in terms of ships and61 percent in terms of berths.

These figures show the problems facing the industry in upgrading ships to meet the new safety and comfort standards. The stricter safety requirements resulting from amendments to

SOLAS—effective 1997—mean that, for ex- ample, more than 40 percent of the current

North America-based fleet—i.e. ships built be- fore 1980—will require major, expensive modi- fications. It is also debatable whether those ships built before 1960 will survive to the end of the decade as the cost of meeting new standards looks prohibitive. If this happens, between 10 and 20 percent of the fleet's total berthage will be lost.

While there have been numerous published studies on the costs of bulk and liner operations, the Drewry Report is the first to analyze in depth the costs of cruise/ferry operations and provides a unique insight into the current and potential economics and costs of the business and, in particular, the impact of impending legislation on future cost levels. Cruise Ship

And Ferry Costs addresses the vital issues facing an industry which will have to cope with radical change brought about by factors both within and outside the industry.

The report contains extensive data on costs and revenues and indicates that, on average, 25 percent of total revenue is derived from on- board sales. Cost projections are given for a five year period and break-even positions for vessels of various sizes are given, indicating that there are considerable economies of scale in cruise and ferry operations. As the data for a 2,050 berth vessel shows in Fig. 1, the total opera- tional break-even cost is $112,000/day or $54/ berth.

To put the report in perspective, the cruise ship and ferry markets are described with back- ground details on their development and their position in world tourism and transport. In addition a key section of the report explores how costs may be controlled by the use of modern management systems and techniques.

FIG. 2

Costs And Revenue Of A Cruise Ship 2,050 Standard Berth

Assuming 100% Occupancy At Brochure Tariffs But

No Contribution From On-board Sales $'000/Day

Total Crew Related Costs 38.60

Ship Related Costs 25.00

Passenger Related Costs 23.35

Administration And General 25.00

Total Non-fixed Costs (Operational Break Even) 111.95

Capital Recovery ($300m x 8 yrs. x 7%) 139.73

Total Break Even 251.68

Tariff Revenue ($140pd) 257.12

Basis cruise ship with berths for 2,050, standard class. Average four day cruise from Florida with two ports of call (often as part of a package holiday). Active cruise days per year: 327

Source: Drewry Shipping Consultants.

Cruise Ship And Ferry Costs In The 1990s:

The Economic Impact Of Increased Safety

Demand, is published by Drewry Shipping Con- sultants, 11 Heron Quay, London E14 4JF.

SLASH OPERATING/

MAINTENANCE COSTS

Hellan® Fluid Strainers remove solids in seawater systems, without interrupting flow.

Solids clean-out takes only 30 seconds, not hours

No baskets to remove or lose

Only half the weight and 60% of space required, compared to duplex strainers

Offered in bronze, monel and stainless steel, in 2" to 20" pipe sizes

Personnel not exposed to contaminants

Meet all major codes, standards and testing including ABS, USCG, and shock and vibration

Low maintenance requirements: change all internal parts in 15 minutes

Currently in use on naval and commercial vessels

For more information, contact:

HELUWnmDSTRAINERS

A product of Cleveland Gear Co. 3249 E. 80th St. • Cleveland, OH 44104 U.S.A.

Phone 216-641-9000 • Fax 216-641-9080

Circle 225 on Reader Service Card

ESGARD BI0-K0TE™/BI0-FL0AT™

BALLAST & VOID TANK COATINGS • Non-Hazardous • Safe • Firm Film • Resists Washout • Not Slippery

Long Life

Single Package

Minimal Surface Prep

Easy to Apply

World Wide "ESGARD PROTECTS YOUR

INVESTMENT AND PRESERVES

YOUR DOLLARS"

P.O. Drawer 2698 cobbosion coatings Lafayette, LA 70502

TEL (318) 234-6327 FAX (318) 234-0113 TLX 586602

Circle 240 on Reader Service Card

HIGH SEAS TECHNOLOGY, INC:

Integrated Marine Electronic

Systems For Yachts And Ships.

Servicing builders and owners worldwide and the ports of: • MIAMI PALM BEACH •FORT LAUDERDALE

Specializing in: •ARPA SATCOM GYRO ECDIS DP •GMDSS INTEGRATED COMMUNICATIONS

Factory ~ Sales - Service ~ Repair 2965 Wo»t Stat* Road 84 Marina Mils

Fort Laudordale, Florida 33312

Tol: 305-584-6000 Fax: 305-587-3007

Circle 291 on Reader Service Card

138

138

140

140