Page 42: of Maritime Reporter Magazine (March 1999)

Read this page in Pdf, Flash or Html5 edition of March 1999 Maritime Reporter Magazine

SHIP REPAIR

FAST® MARINE SEWAGE SYSTEMS

After 20 years of development, today's FAST units have more than twice the rated capacity of the original units. Also, nearly all of the 1,500 FAST units ever installed are still in everyday service.

FAST units are in full accordance with the most recent USCG draft policy which prohibits dilution as a substitute for treatment.

PACE® OIL/WATER SEPARATORS

PACE is the only certified bilge separator that breaks chemical emulsions.

We provide long-term engineering assistance to our customers from this office at no charge. Call or fax us at:

FAST® SYSTEMS 3240 North Broadway, St. Louis, MO 63147-3515, U.S.A.

Tel: 314-621-2536 Fax:314-621-1952 Email: [email protected]

Alan Fleisher, President - Al Spaete, Sales & Service Manager

Circle 228 on Reader Service Card ations ... with a High

Resilient Coupling from the Haley

Clutch and Coupling Company's diverse line of couplings. • over 30 different configurations • ratings from 36,000 lb. in. to 780, • designed for ease of maintenance- • easily replaceable elastomers • unsurpassed service support

Clutch and Coupling Company Inc. 1820 Highway 1 North

Greenville, MS 38701

PH: 601 -332-8716 FAX: 601 -335-0065 42 Circle 235 on Reader Service Card

A Stitch In Time...

Metal Stitching Technology Helps To Cut Costs,

Keeps Vessels Sailing

Up in the bridge the first mate is in charge as the container ship Archangel is setting a course towards Seattle. The gauges indicate that the engine is losing pressure. A call goes down to the cap- tain who is catching up on sleep and the drill begins. The inspection confirms the fears of the ship's engineer - the

Archangel has thrown a conrod in one of its engines.

After the captain radios the owners, they conclude the ship will be in for hundreds of thousands of dollars of repairs and months in dry dock as the

Archangel limps towards port at half speed. An hour later, the office radios in they have contacted an outside vendor and have possible good news, "from what we know about the damage, we think we can get the casting stitched."

Metal surgery, not a widely known repair approach, is practiced by just a few companies across the country. It is intended to save time and money, as a part that may need to be replaced with weeks or months of down time can be repaired in just hours to days.

The process allows broken cast iron or dissimilar metals to be repaired either on-site or in-house.

For example, if the conrod housing on the Archangel had been remedied with a replacement part, the ship would have faced many months in the repair berth.

Instead, a technician was flown in to meet the ship at its home port in

Vladivostok to engineer the repair process.

Repaired at a Fraction of the Cost

The ship took on a load and headed back across the Pacific under half speed to its destination. An insert was machined at the Metal Surgery facility in Milwaukee for the lower bore liner and the cracks in the housing were stitched back to the original surface alignment. The repair took place in a very difficult to access portion of the engine. In 76 days the housing was back in shape with the engine providing full power to the Archangel. Cost of the repair was roughly $120,000 - signifi- cantly less than the estimated six mil- lion dollars to disassemble and totally repair the engine. Upon inspection,

ABS concluded that the operation was an excellent repair.

For castings that suffer cracks or breaks, stitching can restore part casting strength to equal or better than their original shock load capabilities by cre- ating an even stronger structure along the course of the pattern. High-strength locks in the stitched and repaired areas absorb shock loads up to or greater than the original design is able to sustain.

Adding Vital Years

Metal stitching recently was able to

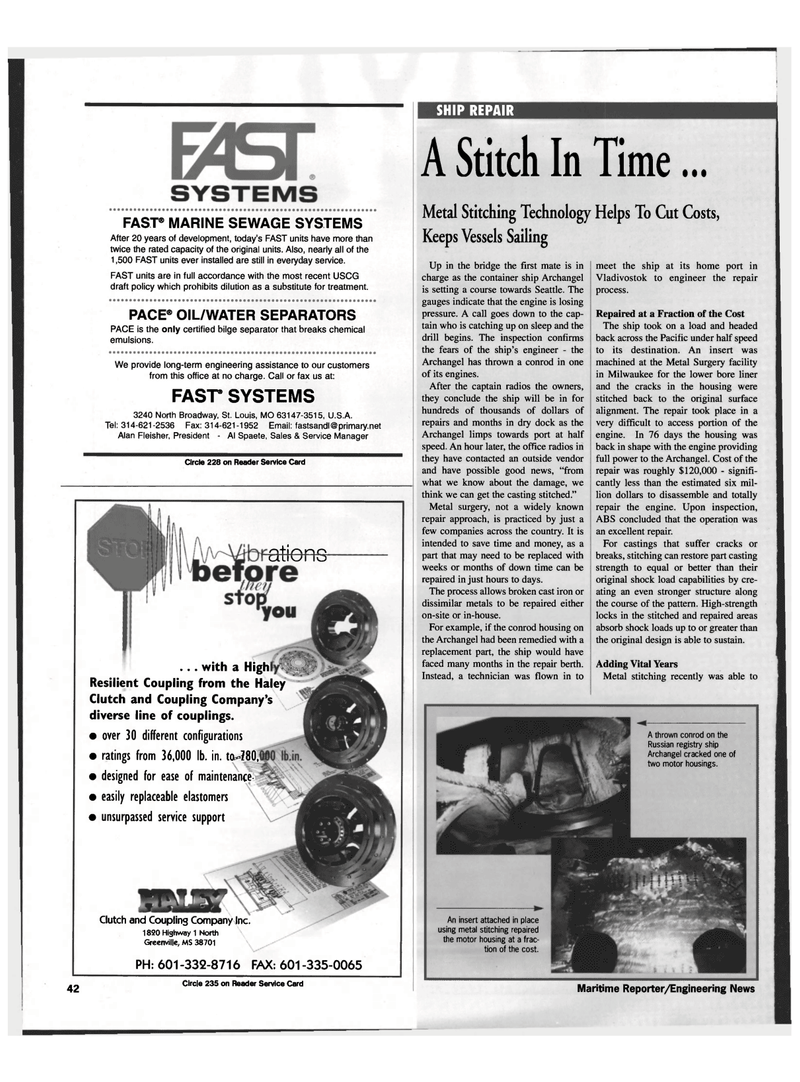

A thrown conrod on the

Russian registry ship

Archangel cracked one of two motor housings.

An insert attached in place using metal stitching repaired the motor housing at a frac- tion of the cost.

Maritime Reporter/Engineering News

41

41

43

43