Page 20: of Offshore Engineer Magazine (Mar/Apr 2014)

Read this page in Pdf, Flash or Html5 edition of Mar/Apr 2014 Offshore Engineer Magazine

Digital Oilfield

Real-time data collection & analysis the need for multiple wells to drill and major safety concern. In fact, the leading

Kepware Technologies’ Stephen hydraulically fracture to tap into the gas cause of death among onshore rig work-

Sponseller discusses how trapped in the shale rock. Companies ers happens while en route to a rig site. automation can improve remote are performing advanced analytics on To satisfy these ef? ciency, reporting, their drilling operations, allowing them and safety requirements, companies are drilling operations.

to predict conditions and events before now remotely collecting data and moni- they happen, based on the outcomes of toring drilling operations 24x7. Corporate ost of the public is unaware previous operations. Improvements in drilling centers are emerging in which that there is an automation rev- ef? ciency have allowed companies to experienced staff can keep a careful eye

M olution in the exploration and reduce drill time to two weeks for some on each of the many concurrent opera- drilling segment of the oil and gas indus- wells, and set drill time goals closer to tions that are going on at different sites try. Like most automation endeavors, this seven to 10 days. in the ? eld to ensure proper operations revolution is driven by the demand for The need for accurate reporting ranges from a safety standpoint and to provide improved ef? ciency, accurate reporting, from demands for corporate and industry instant expert input when needed. These and more stringent safety requirements. analyses to requirements established by drilling centers allow experts to remain

The fast pace of drilling in shale gas government regulations. “on the beach” and not have to travel exploration and production requires Finally, the Deepwater Horizon to remote sites every time their experi- improved process ef? ciency. Improved incident in 2010 has escalated safety ence is needed or an issue arises. Data is ef? ciency demands are partly due to the concerns in both offshore and onshore continually being collected and stored to wide geographic spread of the plays and drilling operations where several differ- empirically develop analytical models ent drilling contractors and service com- that can be compared to the real-time panies may be working simultaneously scenarios of a current drilling operation.

Expert AccessExpert Access on a platform or rigsite. Automation

Real-time data collection Real-time data collection

Importance of data collection can provide means to improve safety in & analysis& analysis these situations. Also, according to an The underlining key for these initiatives with Stephen Sponsellerwith Stephen Sponseller

ARC Insights report issued in 2013 titled is proper data collection from the sites 10 April 2014, 10:00am CT10 April 2014, 10:00am CT “Wireless Strategies for Unconventional and communication with the corpo-

See p. 7 for details.See p. 7 for details.

Reservoirs,” transportation to rigs is a rate drilling centers. There are many

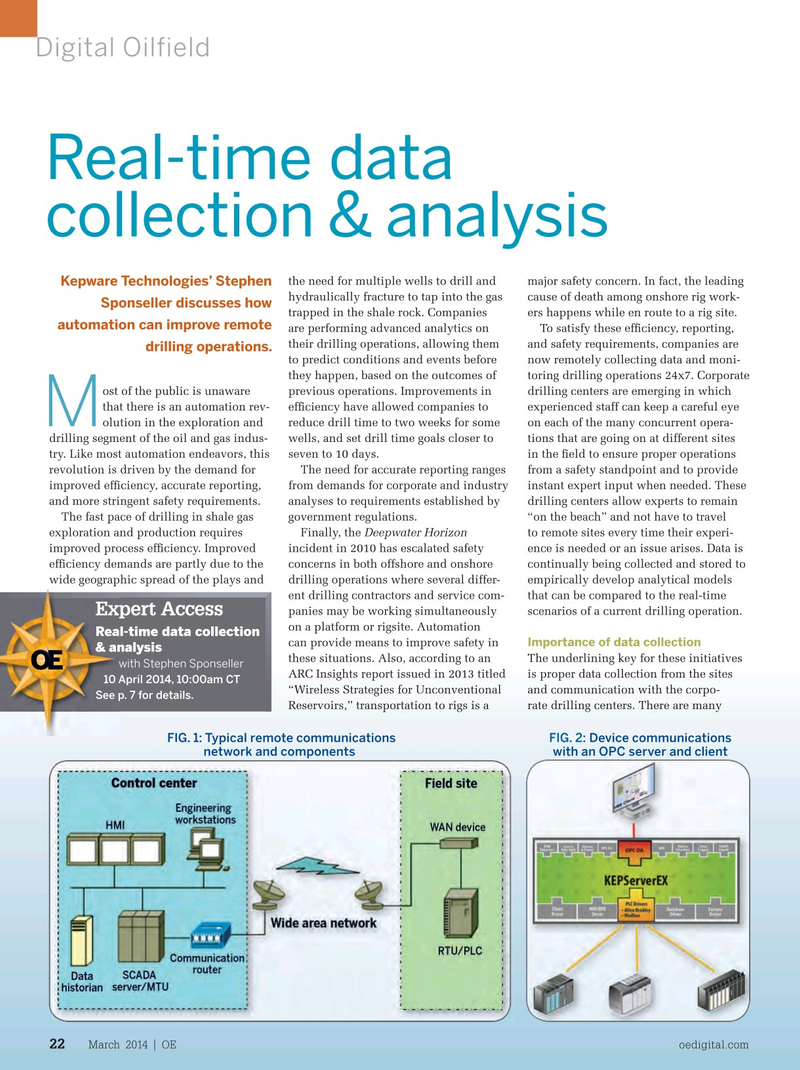

FIG. 1: Typical remote communications FIG. 2: Device communications network and components with an OPC server and client

March 2014 | OE oedigital.com 22 022_OE0314_coverstory_Kepware_B.indd 22 2/21/14 11:39 AM

19

19

21

21