Page 21: of Offshore Engineer Magazine (Mar/Apr 2014)

Read this page in Pdf, Flash or Html5 edition of Mar/Apr 2014 Offshore Engineer Magazine

components in the data collection chain, especially when compared to an Ethernet enterprise directly to an assortment of starting with the equipment, sensors, and network. devices and data sources on a rig can be programmable logic controllers (PLCs) on Communication outages can result troublesome. Serial communications and the rigs; the systems and data collector from weather conditions or physical retries due to unresponsive devices can hosts that are communicating with these obstructions, such as a crane swinging in tie up a network and slow down com- devices; the communication methods the way of a transmitter. The result of an munications. This issue is compounded and networks used to transport the data outage is less data than what is desired, when different applications across an from work sites to shore and the of? ce; often with pockets of missing data. For enterprise are asking for the same data and ? nally, the data storage, analytical industry safety and ef? ciency initiatives, from the devices, causing redundant tools, and human-machine interface this is unacceptable. requests over the network. An OPC server applications that are used to view the located on each rig (acting as a data

How OPC can help data. Each of these components is equally aggregator) would help mitigate these important. OPC, or Open Connectivity via Open challenges and improve data collection

Standards, is a set of communication by the enterprise. The OPC server can

Challenge of collecting major safety concern. In fact, the leading standards for industrial automation communicate directly with the devices remote drilling data cause of death among onshore rig work- devices, applications, and systems. The using their native protocols across the ers happens while en route to a rig site. When someone outside of the oil & gas OPC Foundation (www.opcfoundation. rig’s local network. Once data is col-

To satisfy these ef? ciency, reporting, industry thinks of automation, they most org) owns the standards and works with lected by the server, it can serve it up and safety requirements, companies are likely think of a robot in a factory. When the automation industry to keep stan- to all applications in the enterprise that now remotely collecting data and moni- it comes to communicating with that dards up to date by revising existing require data in real-time. In this scenario, toring drilling operations 24x7. Corporate robot, Ethernet networks in factories are standards and creating new standards there are no device retries or redundant drilling centers are emerging in which relatively easy to set up and they provide when required. The value of OPC lies in requests across the WAN. This alone experienced staff can keep a careful eye very reliable, constant connectivity its interoperability. OPC enables indus- can improve data collection capabilities on each of the many concurrent opera- between the robot and any plant or enter- trial control devices to communicate between an enterprise and the equipment tions that are going on at different sites prise application that needs to communi- with applications that need to send and and systems on a drilling rig.

in the ? eld to ensure proper operations cate with that robot. This is not the case receive data to and from these devices. The OPC speci? cation for histori- from a safety standpoint and to provide in a typical drilling environment, which An OPC server with a robust platform of cal data access, OPC HDA, can further instant expert input when needed. These is often in a remote location and some- device drivers and client connectivity improve the remote data collection drilling centers allow experts to remain times in harsh operating conditions. can communicate directly with a wide capabilities described in the previous “on the beach” and not have to travel Most drill sites today have local area variety of PLCs and other data sources in paragraph. In the scenarios presented to remote sites every time their experi- networks which allow data to ? ow a facility, and then serve up the data via above where connections back to the ence is needed or an issue arises. Data is between equipment and control applica- OPC. In the general automation industry, enterprise can be dropped for a variety of continually being collected and stored to tions on the rig. The challenge is getting this is helpful because it allows applica- reasons, data would be lost during those empirically develop analytical models that data off the rig and back to the enter- tions that need data from various sources drops if real-time OPC communications that can be compared to the real-time prise where the 24x7 remote monitoring to only have to support the OPC stan- were being used. An OPC server on the scenarios of a current drilling operation. and advanced analytics applications are dard—as opposed to supporting all the rig that supports HDA can locally store hosted. Because the rigs are remote, land- different native device protocols associ- the real-time data it acquires from the rig

Importance of data collection line communications are typically not an ated with a wide range of vendors. These devices and play it back to an OPC client

The underlining key for these initiatives option and companies are left with radio, applications are referred to as “OPC application via OPC HDA when adequate is proper data collection from the sites cellular, satellite or some other form of clients.” communications are available. When and communication with the corpo- wireless communication that have low Remote communications through communications are not available, the rate drilling centers. There are many bandwidth and high latency (time delay), a wide-area network (WAN) from the server will continue to store the real-time

FIG. 2: Device communications

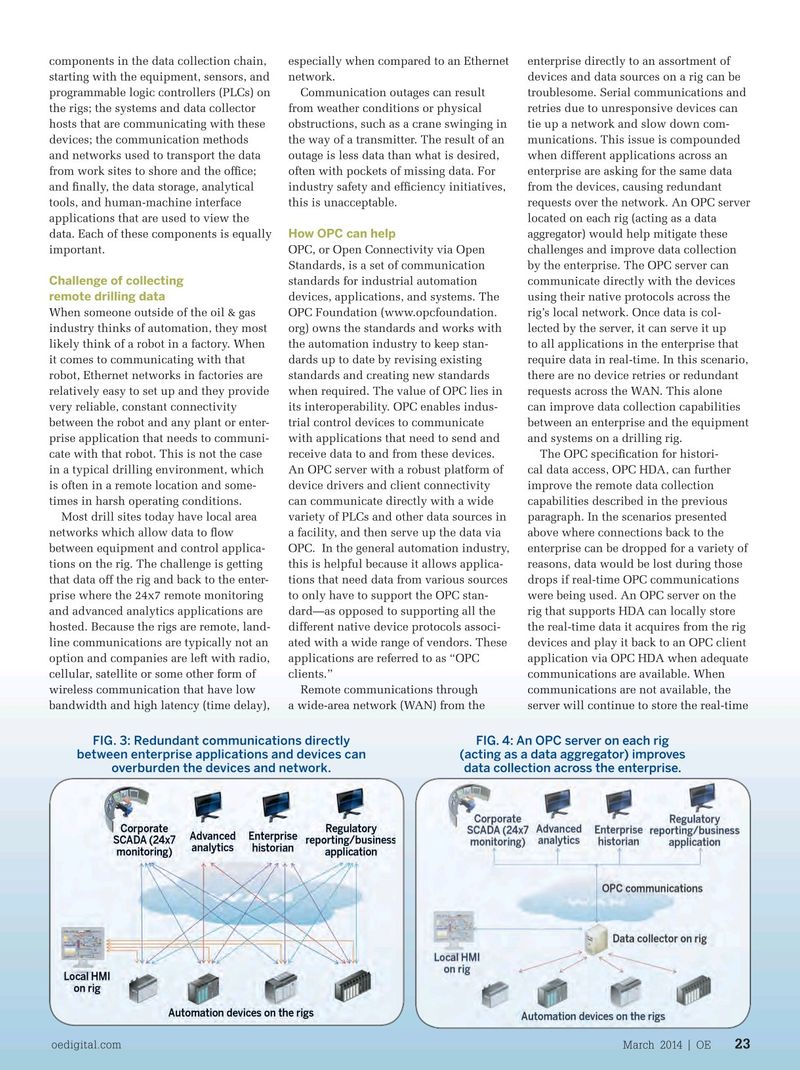

FIG. 3: Redundant communications directly FIG. 4: An OPC server on each rig with an OPC server and client between enterprise applications and devices can (acting as a data aggregator) improves overburden the devices and network. data collection across the enterprise.

oedigital.com March 2014 | OE 23 022_OE0314_coverstory_Kepware_B.indd 23 2/21/14 11:39 AM

20

20

22

22