Page 50: of Offshore Engineer Magazine (Apr/May 2014)

Read this page in Pdf, Flash or Html5 edition of Apr/May 2014 Offshore Engineer Magazine

EPIC

Testing subsea

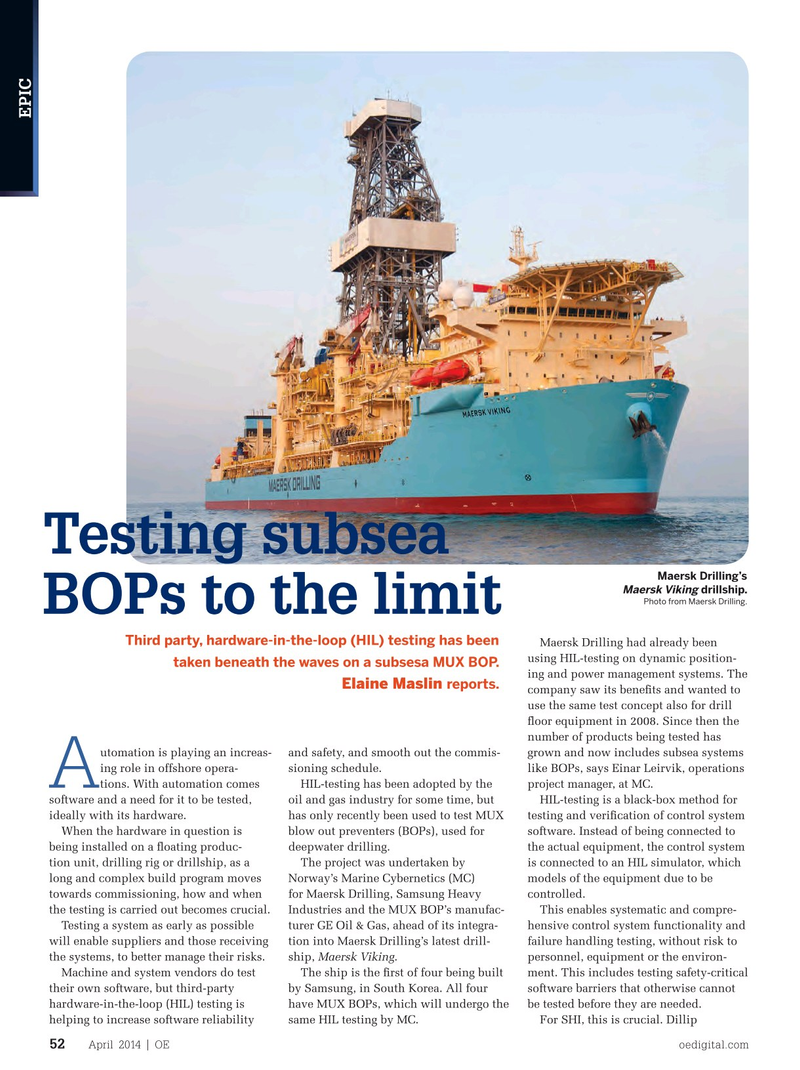

Maersk Drilling’s

Maersk Viking drillship.

Photo from Maersk Drilling.

BOPs to the limit

Third party, hardware-in-the-loop (HIL) testing has been

Maersk Drilling had already been using HIL-testing on dynamic position- taken beneath the waves on a subsesa MUX BOP. ing and power management systems. The

Elaine Maslin reports. company saw its bene? ts and wanted to use the same test concept also for drill ? oor equipment in 2008. Since then the number of products being tested has utomation is playing an increas- and safety, and smooth out the commis- grown and now includes subsea systems ing role in offshore opera- sioning schedule. like BOPs, says Einar Leirvik, operations

A tions. With automation comes HIL-testing has been adopted by the project manager, at MC.

software and a need for it to be tested, oil and gas industry for some time, but HIL-testing is a black-box method for ideally with its hardware. has only recently been used to test MUX testing and veri? cation of control system

When the hardware in question is blow out preventers (BOPs), used for software. Instead of being connected to being installed on a ? oating produc- deepwater drilling. the actual equipment, the control system tion unit, drilling rig or drillship, as a The project was undertaken by is connected to an HIL simulator, which long and complex build program moves Norway’s Marine Cybernetics (MC) models of the equipment due to be towards commissioning, how and when for Maersk Drilling, Samsung Heavy controlled. the testing is carried out becomes crucial. Industries and the MUX BOP’s manufac- This enables systematic and compre-

Testing a system as early as possible turer GE Oil & Gas, ahead of its integra- hensive control system functionality and will enable suppliers and those receiving tion into Maersk Drilling’s latest drill- failure handling testing, without risk to the systems, to better manage their risks. ship, Maersk Viking. personnel, equipment or the environ-

Machine and system vendors do test The ship is the ? rst of four being built ment. This includes testing safety-critical their own software, but third-party by Samsung, in South Korea. All four software barriers that otherwise cannot hardware-in-the-loop (HIL) testing is have MUX BOPs, which will undergo the be tested before they are needed.

helping to increase software reliability same HIL testing by MC. For SHI, this is crucial. Dillip

April 2014 | OE oedigital.com 52 000_OE0414_EPIC3_Cybernetics.indd 52 3/22/14 10:09 PM

49

49

51

51