Page 51: of Offshore Engineer Magazine (Apr/May 2014)

Read this page in Pdf, Flash or Html5 edition of Apr/May 2014 Offshore Engineer Magazine

Moharana, senior manager-instrumen- Sen, subsea section manager, electri- management up-front in the process.

EPIC tation, SHI, Geoje Shipyard, says: “HIL cal controls team, Houston. “What HIL “At the end of the complete cycle, the testing means we can thoroughly test allows is the control system to be tested quality of the product remains the same, the software. Normally, we have to with the hardware that it is to be inter- it is just a matter of timing, when you are believe the vendor, who is supplying the faced with in the ship at a later date. It managing the risks out. We are allowing software, and do not have a mechanism gives an additional level of confdence the customer to focus on the ship build- ourselves to 100% check the software and allows an additional level of risk ing and the assembly, instead of dealing before it is commissioned. Introducing third-party HIL testing means the soft-

Schematic from the PDF ware developed by the vendor can be illustrating HIL testing. thoroughly checked and we can make

Image from Marine Cybernetics.

sure it is robust.”

This then reduces the risk that the software could fail during an operation, which could potentially cost millions of dollars in lost revenue due to downtime for fault-fnding and corrective work. For a subsea BOP, removing any potential for failure, especially in deep water, is even more important, Moharana says, safety

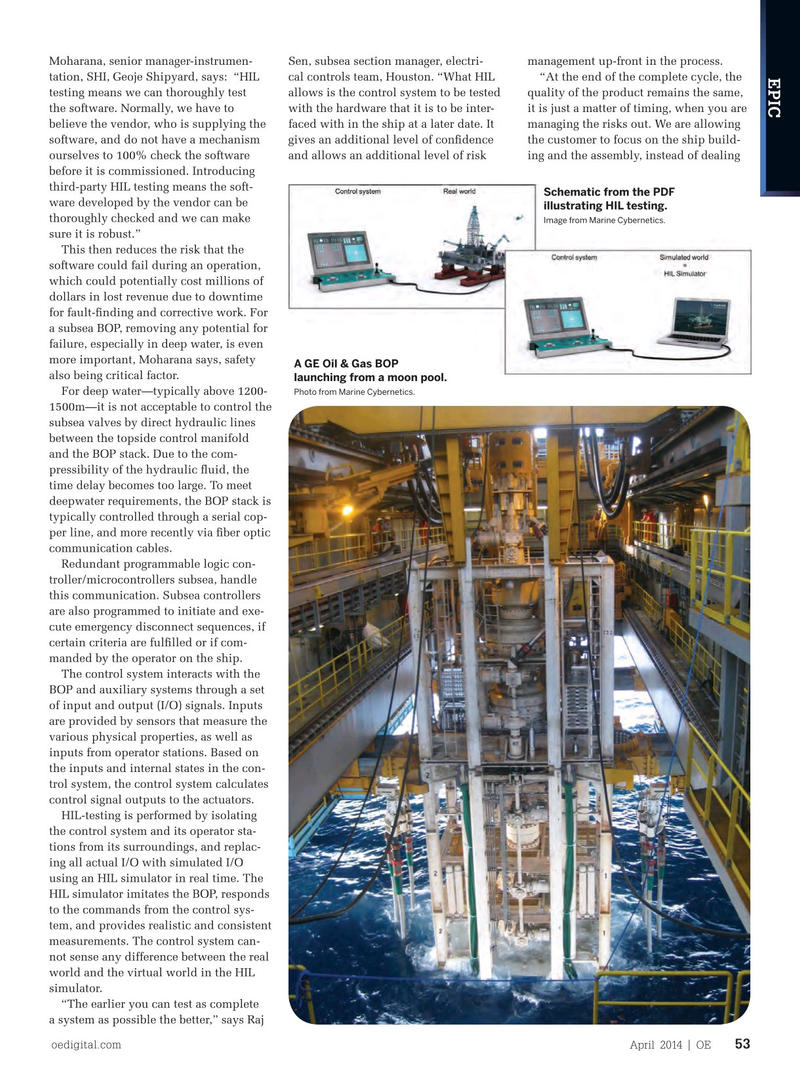

A GE Oil & Gas BOP also being critical factor. launching from a moon pool.

Photo from Marine Cybernetics.

For deep water—typically above 1200- 1500m—it is not acceptable to control the subsea valves by direct hydraulic lines between the topside control manifold and the BOP stack. Due to the com- pressibility of the hydraulic fuid, the time delay becomes too large. To meet deepwater requirements, the BOP stack is typically controlled through a serial cop- per line, and more recently via fber optic communication cables.

Redundant programmable logic con- troller/microcontrollers subsea, handle this communication. Subsea controllers are also programmed to initiate and exe- cute emergency disconnect sequences, if

Maersk Drilling had already been certain criteria are fulflled or if com- using HIL-testing on dynamic position- manded by the operator on the ship.

ing and power management systems. The The control system interacts with the company saw its benefts and wanted to BOP and auxiliary systems through a set use the same test concept also for drill of input and output (I/O) signals. Inputs foor equipment in 2008. Since then the are provided by sensors that measure the number of products being tested has various physical properties, as well as grown and now includes subsea systems inputs from operator stations. Based on like BOPs, says Einar Leirvik, operations the inputs and internal states in the con- project manager, at MC. trol system, the control system calculates

HIL-testing is a black-box method for control signal outputs to the actuators.

testing and verifcation of control system HIL-testing is performed by isolating software. Instead of being connected to the control system and its operator sta- the actual equipment, the control system tions from its surroundings, and replac- is connected to an HIL simulator, which ing all actual I/O with simulated I/O models of the equipment due to be using an HIL simulator in real time. The controlled. HIL simulator imitates the BOP, responds

This enables systematic and compre- to the commands from the control sys- hensive control system functionality and tem, and provides realistic and consistent failure handling testing, without risk to measurements. The control system can- personnel, equipment or the environ- not sense any difference between the real ment. This includes testing safety-critical world and the virtual world in the HIL software barriers that otherwise cannot simulator. be tested before they are needed. “The earlier you can test as complete

For SHI, this is crucial. Dillip a system as possible the better,” says Raj oedigital.com April 2014 | OE 53 000_OE0414_EPIC3_Cybernetics.indd 53 3/22/14 10:09 PM

50

50

52

52