Page 37: of Offshore Engineer Magazine (Oct/Nov 2014)

Read this page in Pdf, Flash or Html5 edition of Oct/Nov 2014 Offshore Engineer Magazine

Higher Availability with

Full Budget Control

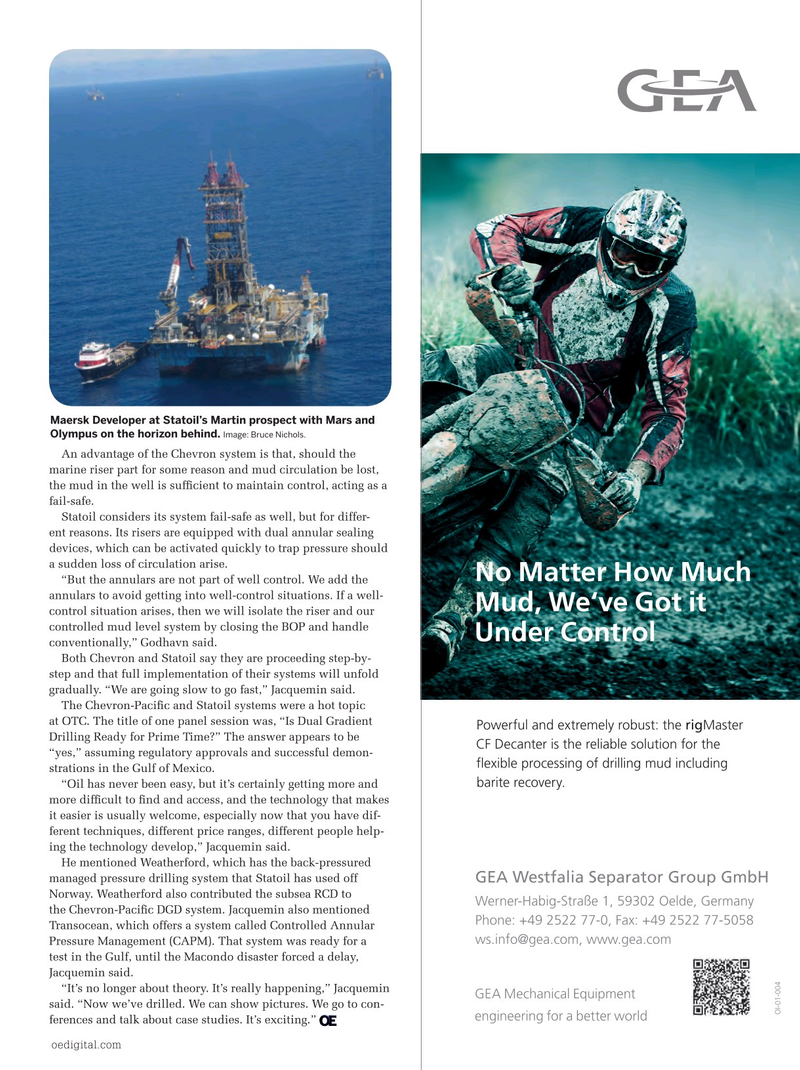

Maersk Developer at Statoil’s Martin prospect with Mars and

Olympus on the horizon behind. Image: Bruce Nichols.

An advantage of the Chevron system is that, should the marine riser part for some reason and mud circulation be lost, the mud in the well is suffcient to maintain control, acting as a fail-safe.

Statoil considers its system fail-safe as well, but for differ- ent reasons. Its risers are equipped with dual annular sealing devices, which can be activated quickly to trap pressure should a sudden loss of circulation arise.

No Matter How Much “But the annulars are not part of well control. We add the annulars to avoid getting into well-control situations. If a well-

Mud, We‘ve Got it control situation arises, then we will isolate the riser and our controlled mud level system by closing the BOP and handle

Under Control conventionally,” Godhavn said.

Both Chevron and Statoil say they are proceeding step-by- step and that full implementation of their systems will unfold gradually. “We are going slow to go fast,” Jacquemin said.

The Chevron-Pacifc and Statoil systems were a hot topic at OTC. The title of one panel session was, “Is Dual Gradient

Powerful and extremely robust: the rigMaster

Drilling Ready for Prime Time?” The answer appears to be

CF Decanter is the reliable solution for the “yes,” assuming regulatory approvals and successful demon- flexible processing of drilling mud including strations in the Gulf of Mexico.

barite recovery. “Oil has never been easy, but it’s certainly getting more and more diffcult to fnd and access, and the technology that makes it easier is usually welcome, especially now that you have dif- ferent techniques, different price ranges, different people help- ing the technology develop,” Jacquemin said.

He mentioned Weatherford, which has the back-pressured managed pressure drilling system that Statoil has used off

GEA Westfalia Separator Group GmbH

Norway. Weatherford also contributed the subsea RCD to

Werner-Habig-Straße 1, 59302 Oelde, Germany the Chevron-Pacifc DGD system. Jacquemin also mentioned

Phone: +49 2522 77-0, Fax: +49 2522 77-5058

Transocean, which offers a system called Controlled Annular [email protected], www.gea.com

Pressure Management (CAPM). That system was ready for a test in the Gulf, until the Macondo disaster forced a delay,

Jacquemin said.

“It’s no longer about theory. It’s really happening,” Jacquemin

GEA Mechanical Equipment said. “Now we’ve drilled. We can show pictures. We go to con-

OI-01-004 engineering for a better world ferences and talk about case studies. It’s exciting.” oedigital.com 000_OE1014_D&C1_Bruce.indd 39 9/23/14 1:19 PM

36

36

38

38