Page 66: of Offshore Engineer Magazine (Oct/Nov 2014)

Read this page in Pdf, Flash or Html5 edition of Oct/Nov 2014 Offshore Engineer Magazine

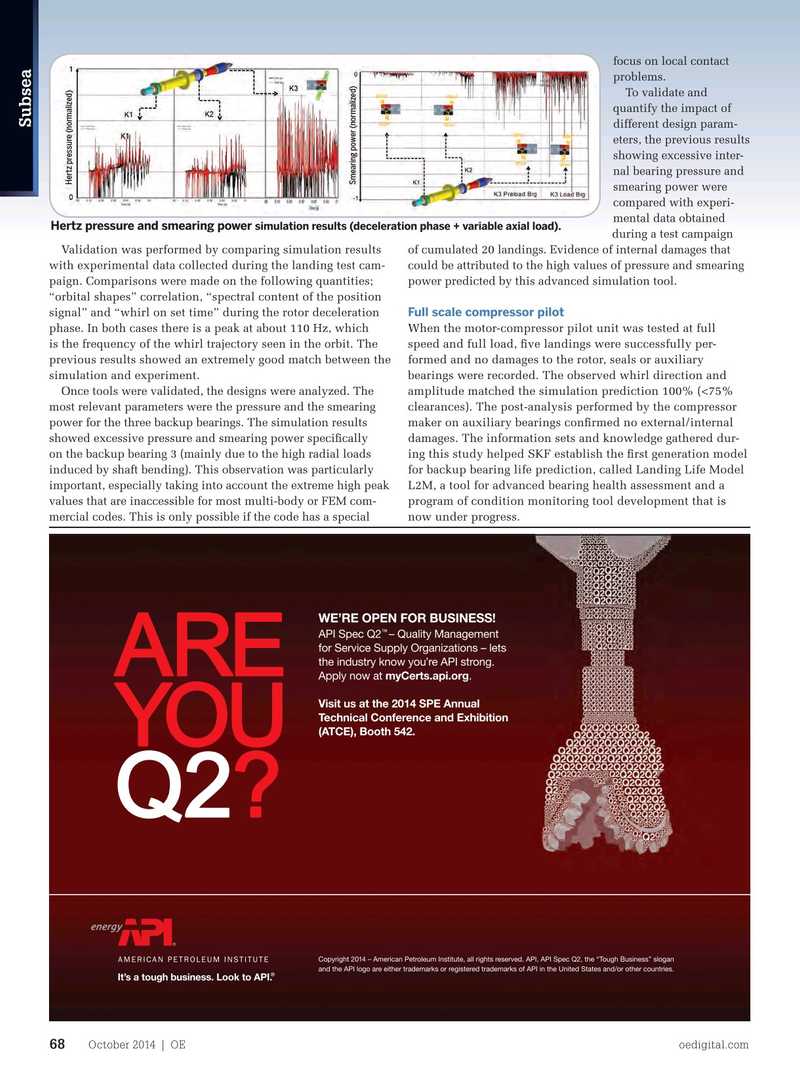

focus on local contact problems.

To validate and quantify the impact of

Subsea different design param- eters, the previous results showing excessive inter- nal bearing pressure and smearing power were compared with experi- mental data obtained

Hertz pressure and smearing power simulation results (deceleration phase + variable axial load).

during a test campaign

Validation was performed by comparing simulation results of cumulated 20 landings. Evidence of internal damages that with experimental data collected during the landing test cam- could be attributed to the high values of pressure and smearing paign. Comparisons were made on the following quantities; power predicted by this advanced simulation tool.

“orbital shapes” correlation, “spectral content of the position

Full scale compressor pilot signal” and “whirl on set time” during the rotor deceleration

When the motor-compressor pilot unit was tested at full phase. In both cases there is a peak at about 110 Hz, which speed and full load, ? ve landings were successfully per- is the frequency of the whirl trajectory seen in the orbit. The formed and no damages to the rotor, seals or auxiliary previous results showed an extremely good match between the bearings were recorded. The observed whirl direction and simulation and experiment. amplitude matched the simulation prediction 100% (<75%

Once tools were validated, the designs were analyzed. The clearances). The post-analysis performed by the compressor most relevant parameters were the pressure and the smearing maker on auxiliary bearings con? rmed no external/internal power for the three backup bearings. The simulation results damages. The information sets and knowledge gathered dur- showed excessive pressure and smearing power speci? cally ing this study helped SKF establish the ? rst generation model on the backup bearing 3 (mainly due to the high radial loads for backup bearing life prediction, called Landing Life Model induced by shaft bending). This observation was particularly

L2M, a tool for advanced bearing health assessment and a important, especially taking into account the extreme high peak program of condition monitoring tool development that is values that are inaccessible for most multi-body or FEM com- now under progress.

mercial codes. This is only possible if the code has a special

WE’RE OPEN FOR BUSINESS! ™

API Spec Q2 – Quality Management for Service Supply Organizations – lets the industry know you’re API strong.

ARE

Apply now at myCerts.api.org.

Visit us at the 2014 SPE Annual

Technical Conference and Exhibition (ATCE), Booth 542.

YOU

Q2?

Copyright 2014 – American Petroleum Institute, all rights reserved. API, API Spec Q2, the “Tough Business” slogan and the API logo are either trademarks or registered trademarks of API in the United States and/or other countries.

®

It’s a tough business. Look to API.

OffshoreEngineer_HalfPage_Q2Ad.indd 1 8/11/14 9:32 AM

October 2014 | OE oedigital.com 68 066_OE1014_Subsea7.indd 68 9/24/14 1:14 AM

65

65

67

67