Page 67: of Offshore Engineer Magazine (Oct/Nov 2014)

Read this page in Pdf, Flash or Html5 edition of Oct/Nov 2014 Offshore Engineer Magazine

Dynamics response of thrust bearing

SubseaEyebrow

Much has been written on the modeling of non-laminated (solid) axial bearings, including eddy currents induced in a solid magnetic frame; however, in most cases the proposed model is de? ned only in frequency domain and is only valid regarding small air gap variations. Even if it is very helpful to use these simple analytical models during the development phase of a new axial magnetic bearing, they do not allow the time response of the thrust bearing while facing a rapid tran- sient and high amplitude force to be predicted. These types of disturbance are usually encountered when the compressor is operating near the surge line or in other abnormal process

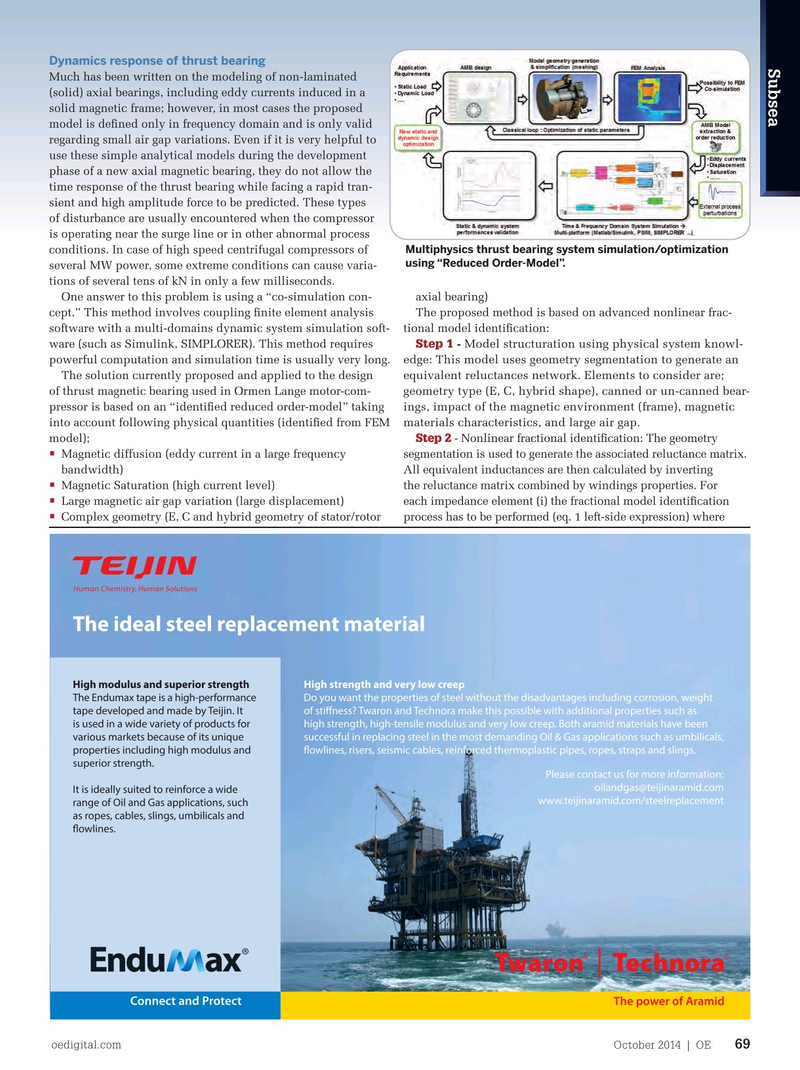

Multiphysics thrust bearing system simulation/optimization conditions. In case of high speed centrifugal compressors of using “Reduced Order-Model”.

several MW power, some extreme conditions can cause varia- tions of several tens of kN in only a few milliseconds.

One answer to this problem is using a “co-simulation con- axial bearing) cept.” This method involves coupling ? nite element analysis The proposed method is based on advanced nonlinear frac- software with a multi-domains dynamic system simulation soft- tional model identi? cation:

Step 1 - Model structuration using physical system knowl- ware (such as Simulink, SIMPLORER). This method requires edge: This model uses geometry segmentation to generate an powerful computation and simulation time is usually very long. equivalent reluctances network. Elements to consider are;

The solution currently proposed and applied to the design geometry type (E, C, hybrid shape), canned or un-canned bear- of thrust magnetic bearing used in Ormen Lange motor-com- ings, impact of the magnetic environment (frame), magnetic pressor is based on an “identi? ed reduced order-model” taking materials characteristics, and large air gap.

into account following physical quantities (identi? ed from FEM model); Step 2 - Nonlinear fractional identi? cation: The geometry •

Magnetic diffusion (eddy current in a large frequency segmentation is used to generate the associated reluctance matrix. bandwidth) All equivalent inductances are then calculated by inverting •

Magnetic Saturation (high current level) the reluctance matrix combined by windings properties. For •

Large magnetic air gap variation (large displacement) each impedance element (i) the fractional model identi? cation •

Complex geometry (E, C and hybrid geometry of stator/rotor process has to be performed (eq. 1 left-side expression) where

The ideal steel replacement material

High modulus and superior strength High strength and very low creep

The Endumax tape is a high-performance Do you want the properties of steel without the disadvantages including corrosion, weight tape developed and made by Teijin. It of stifness? Twaron and Technora make this possible with additional properties such as is used in a wide variety of products for high strength, high-tensile modulus and very low creep. Both aramid materials have been various markets because of its unique successful in replacing steel in the most demanding Oil & Gas applications such as umbilicals, properties including high modulus and fowlines, risers, seismic cables, reinforced thermoplastic pipes, ropes, straps and slings. superior strength.

Please contact us for more information: [email protected]

It is ideally suited to reinforce a wide www.teijinaramid.com/steelreplacement range of Oil and Gas applications, such as ropes, cables, slings, umbilicals and fowlines. oedigital.com October 2014 | OE 69

Advertentie Oil and Gas.indd 1 13-8-2014 14:09:12 066_OE1014_Subsea7.indd 69 9/24/14 1:15 AM

66

66

68

68