WiSub has the solution to repower AUVs and transmit data under water.

Autonomous underwater vehicles (AUV) are increasingly used in the oil and gas industry, especially for subsea field monitoring. One of the limiting factors in its use has been the need to recover it to the surface after relatively short periods of time. WiSub believes it has a definitive solution to this problem. AUV systems have always been a target application for pin-less power and data transfer, due to the significant challenges posed with using conventional connectors for this type of connection. WiSub combines the latest methods in resonant power transfer with a revolutionary application of very high frequencies underwater to transmit data and power over short gaps of seawater, reliably maintaining the ability to connect and disconnect without increasing the risk of connection failure or degraded performance, a potentially game changing subsea technology.

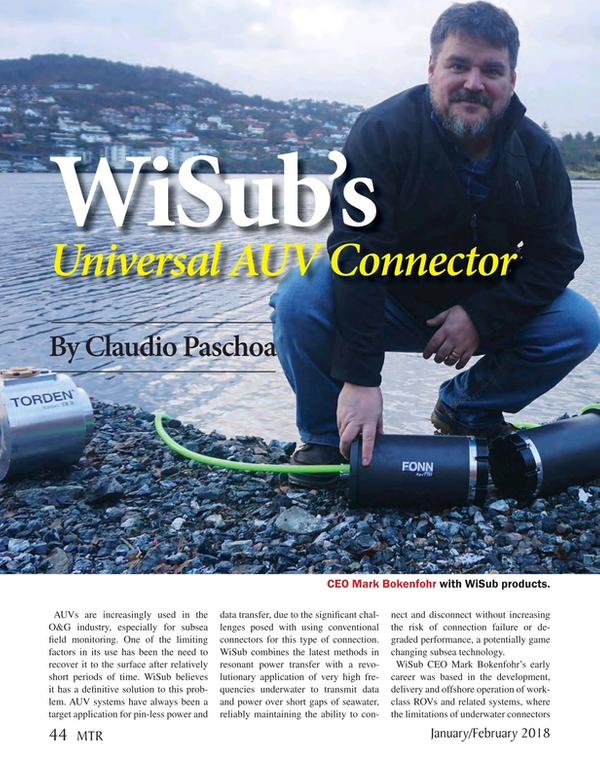

WiSub CEO Mark Bokenfohr’s early career was based in the development, delivery and offshore operation of work-class remotely operated underwater vehicles (ROV) and related systems, where the limitations of underwater connectors can be readily observed. “Having used low-speed inductive modems as an ROV pilot during oceanographic science operations, I was convinced that pin-less connectors should be developed for the oil and gas industry as well, though it took another decade, a few changes of country, and the right timing before I took the leap to build a company that would deliver such solutions. Officially the UAC project is named “Universal AUV Pin-less Charging and Data Transfer Interface”. Internally we call this project “Pin-less AUV Interface” or PAX.” WiSub has developed significant advancements to the advancement of state-of-the-art underwater connection, however we must share credit to the development of earlier pin-less connection technologies for providing us with the inspiration to go farther and dream bigger,” said Bokenfohr.

When speaking to Bokenfohr, you immediately feel the passion and knowledge he has for the potential of the Universal AUV Connector (UAC). It’s important to look at the history involved in this breakthrough. “Pin-less inductive connectors have been in use underwater for decades, developed to overcome the significant limitations of pinned wet-mate connectors. Some of the earliest applications in this area were simply split transformer halves, delivering wireless power based on the principles patented by Nikola Tesla a hundred years earlier. Data has also been transferred wirelessly through water via electromagnetics (EM) for decades,” explains Bokenfohr. Yet in order for the UAC concept to come of age, key technological developments were necessary. “Significant and relatively recent developments in through-air technologies have enabled a leap forward in the state-of-the-art for EM-based underwater connection. The commercial availability of electric cars has also spawned the development of higher-power wireless charging; WiSub developed our Torden product in collaboration with one such developer who was transferring 18kW into a moving electric car. WiSub marries the latest methods and circuits possible in resonant power transfer with the revolutionary application of very high frequencies underwater to transmit data and power over short gaps of seawater. We have seen further by standing on the shoulders of giants.”

According to Bokenfohr, there are some specific characteristics of the pin-less connection that allow the UAC to maintain reliable data and power transfer underwater, which are vital in enabling a dependable AUV docking station – “Maintaining reliable connection means maintaining the ability to connect and disconnect without increasing risk of failure or degraded performance. Legacy pinned connections can perform reasonably reliably if handled carefully and plugged in only once; some might consider them like a solder joint – connected once and not intended to be separated. To keep the connector’s precision moving parts safe and the connection reliable over several wet-mate cycles is much more challenging due to the need to seal dynamically against corrosive high-pressure water, align pins perfectly every time while attempting to seal and re-seal without incurring ground faults or failure. Contaminants in the water and rough operator handling exacerbate the problem of sealing and alignment. The basic physics of pin-to-socket construction also limits the speeds possible for data transfer due to the long unshielded, untwisted pin lengths that introduce the possibility of interference. Pin-less connection is inherently more reliable over multiple mating cycles since there are no dynamic seals that wear out, a far more forgiving mating tolerance, immunity to contamination and no pins to align, break or bend. A reduced mechanical complexity is valuable in increasing reliability, and justifies the application of solid-state electronics. There are further enhancements that an intelligent connector can provide which ‘simple’ pins cannot, such as localized network diagnostics.”

One of the vital breakthroughs that made the UAC concept viable relates to WiSub’s patented high-speed, high frequency microwave electronics technology – “EM-based communication has been known for decades in the radio-frequency range (below 300 MHz), and has been applied to low-speed data transmission over short distances (some meters). High frequency data transmission has been ignored due to its very high attenuation in seawater – GHz-level EM wave propagation is not possible beyond 10 centimeters through seawater, and more practically only useful under 5 centimeters. This was never considered a practical distance for ‘wireless communication’ since ‘transferring over some distance’ was always understood for ‘wireless’ technology. High-frequency EM works very well for pin-less connectors though, and since it was never obvious to others, we were able to secure patents for this inventive step in underwater communication,” explained Bokenfohr. It is also interesting to note the advantages of this technology over traditional low-frequency RF, inductive or acoustic technologies. High data transmission speed over wide bandwidth is the main advantage offered by WiSub’s microwave-based underwater data link, starting at 100Mbps and extending past 1Gbps in development. “This high-speed advantage is possible due to the frequencies involved, which requires small (micro) wavelengths, which also happens to be the same feature that prevents long-distance travel of these waves. Microwaves are defined to operate in the 300MHz to 300GHz frequency range; the other technologies applied in the field of underwater communication typically operate at far lower frequencies, and correspondingly lower data rates. Data speeds of kbps (kilobits per second) are possible with acoustic communications. Radio-frequency communication links (within the 3 KHz to 300 GHz range) are able to achieve similar data speeds over some meters. Inductive links used for power transfer are often also used for data transfer, with small separation between frequencies, which presents some risk of interference as well. An additional practical benefit of using microwaves at GHz for data transfer and longer wavelengths at kHz for power transfer is the large separation between frequencies, which avoids interference issues. Additionally, acoustic communications are adversely affected by turbidity and noise in the water column, which does not affect EM-based systems,” said Bokenfohr.

The search for a robust and reliable subsea AUV docking station has been going on for at least a decade. With the increase in size, depth and complexity of subsea oil and gas production fields, the need for long term AUV and ROV docking has greatly increased. In terms of simplifying operational logistics and decreasing support vessel costs, the possibilities offered by the UAC may truly be a game changer. According to Bokenfohr “AUV docking is extremely risky unless established via a pin-less connector. Docking has previously been demonstrated by others using wireless underwater technologies, but these developments have been limited in compatibility with other systems and specific to certain vehicles and networks. The PAX connection system will increase the viability of long-term subsea docking stations by delivering a universal connection system that is compatible between multiple AUV systems, encouraging deployment and proliferation of the technology throughout all subsea industries internationally. An additional result of the project will be the ability to deliver power from the AUV to distributed sensors in the underwater environment, as well as harvesting data gathered by such sensors. Sensors deployed underwater and not connected to an expensive cabled network are limited in battery life, data transmission speed and communication distance. Enabling the AUV to be ‘subsea resident permits localized power distribution without need for a cabled network, shortening the communication distance to centimeters while increasing the data communication speed to Mbps instead of the limits imposed by acoustic communication physics.”

The main characteristics and capabilities of the UAC and its depth rating showcase the many possible uses it may have for the O&G industry. “The PAX project will deliver two discrete interfaces, technology within these systems both based on WiSub’s award-winning Torden and Maelstrom products. The Torden PAX development will be used for charging the AUV, and the new development Fonn will be used for charging from the AUV. Both will apply WiSub’s patented half-duplex 100Mbps microwave-based data link.”

These are the gap tolerances on the connection and its data and power transfer capabilities - 10mm gap. 100Mbps data transfer, 250W@24vdc (Fonn instrument interface) and 3kW@300vdc (Torden PAX AUV interface). “We have not observed that depth affects pin-less connector performance, except in the case where materials compress (e.g. encapsulation material around transducer heads) and seawater gap increases. Further research in the project will confirm operational parameters of the project’s results. The project’s planned research into calcareous deposits is expected to yield additional useful information on environmental factors that might influence pin-less connector performance.” Bokenfohr also pointed out the diversity and importance of his partners in the project: “The PAX project brings together a diverse group of participants, some who are in direct competition with each other, but will all benefit from the developments. Several of the project participants have existing commercial relationships, and they include AUV manufacturers, AUV operators, acoustic communication systems providers, subsea infrastructure stakeholders and academia, who all play a role in the project. Each brings their own unique competence and their invaluable experience and advice to the development of the most relevant results.”

WiSub believes it will have UAC technology operational for use in a deepwater AUV docking station in the near future, with one system to be deployed by the end of this year. “The Fonn 250W development is in its final stages now, the first hardware to be deployed within December 2017. Torden PAX 3kW will be deployed in Q2/Q3 2018. Both resident ROV and AUV systems will be enabled via these developments. WiSub’s existing products are however already deployed and in use as AUV docking interfaces with customers in North America. WiSub’s innovation in high-frequency data transfer has added an essential component to enable faster data transfer speeds, an advancement which was recognized at OTC 2015 through a panel of industry experts awarding WiSub’s Maelstrom connection system a Spotlight on New Technology Award. Maelstrom was developed to be our first flagship product to demonstrate the capabilities of high-speed pin-less communication over microwave frequencies, coupled with inductive power transfer methods to meet industry needs for repeatable reliable connection. Torden also took home its own Spotlight award in May of 2017, confirming that the industry continues to see great value in pin-less underwater connector solutions,” concludes Bokenfohr.