Page 43: of Maritime Logistics Professional Magazine (Mar/Apr 2019)

Container Ports

Read this page in Pdf, Flash or Html5 edition of Mar/Apr 2019 Maritime Logistics Professional Magazine

TECH FILE

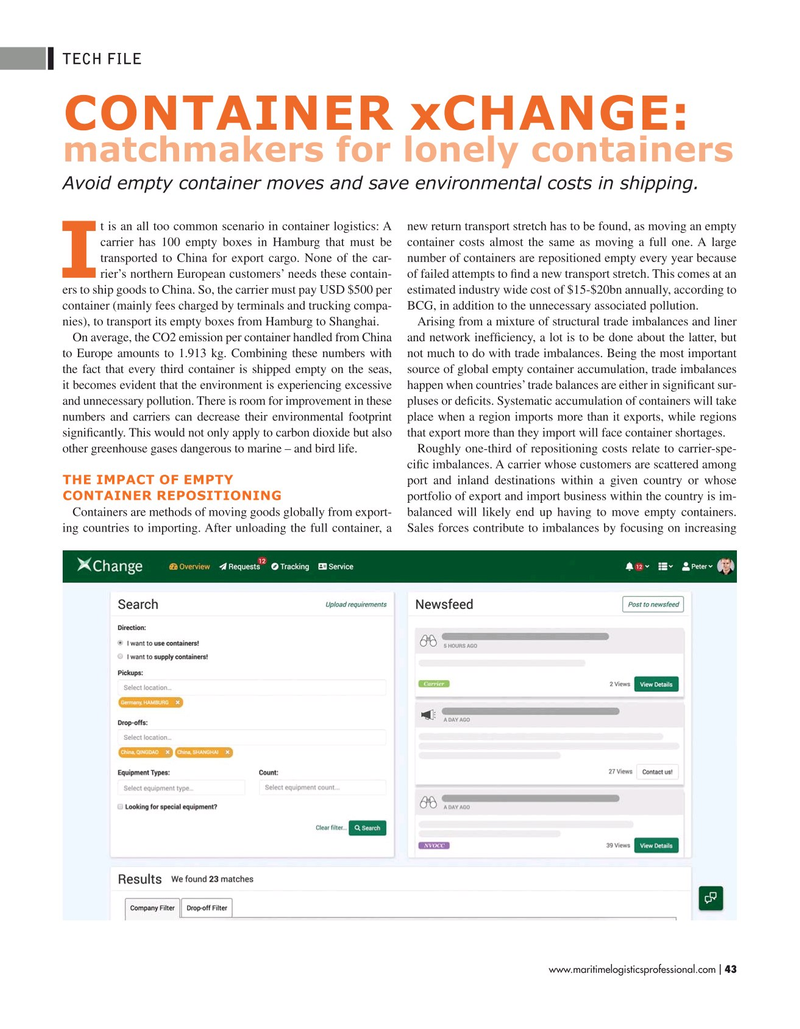

CONTAINER xCHANGE: matchmakers for lonely containers

Avoid empty container moves and save environmental costs in shipping. t is an all too common scenario in container logistics: A new return transport stretch has to be found, as moving an empty carrier has 100 empty boxes in Hamburg that must be container costs almost the same as moving a full one. A large transported to China for export cargo. None of the car- number of containers are repositioned empty every year because

Irier’s northern European customers’ needs these contain- of failed attempts to ?nd a new transport stretch. This comes at an ers to ship goods to China. So, the carrier must pay USD $500 per estimated industry wide cost of $15-$20bn annually, according to container (mainly fees charged by terminals and trucking compa- BCG, in addition to the unnecessary associated pollution.

nies), to transport its empty boxes from Hamburg to Shanghai. Arising from a mixture of structural trade imbalances and liner

On average, the CO2 emission per container handled from China and network inef?ciency, a lot is to be done about the latter, but to Europe amounts to 1.913 kg. Combining these numbers with not much to do with trade imbalances. Being the most important the fact that every third container is shipped empty on the seas, source of global empty container accumulation, trade imbalances it becomes evident that the environment is experiencing excessive happen when countries’ trade balances are either in signi?cant sur- and unnecessary pollution. There is room for improvement in these pluses or de?cits. Systematic accumulation of containers will take numbers and carriers can decrease their environmental footprint place when a region imports more than it exports, while regions signi?cantly. This would not only apply to carbon dioxide but also that export more than they import will face container shortages.

other greenhouse gases dangerous to marine – and bird life. Roughly one-third of repositioning costs relate to carrier-spe- ci?c imbalances. A carrier whose customers are scattered among

THE IMPACT OF EMPTY port and inland destinations within a given country or whose

CONTAINER REPOSITIONING portfolio of export and import business within the country is im-

Containers are methods of moving goods globally from export- balanced will likely end up having to move empty containers. ing countries to importing. After unloading the full container, a Sales forces contribute to imbalances by focusing on increasing www.maritimelogisticsprofessional.com 43

I

42

42

44

44