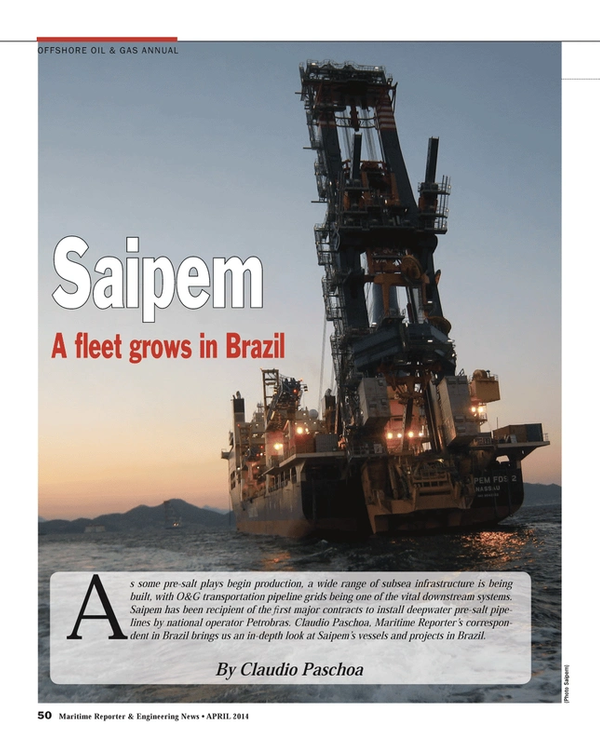

Saipem: A Fleet Grows in Brazil

As some pre-salt plays begin production, a wide range of subsea infrastructure is being built, with O&G transportation pipeline grids being one of the vital downstream systems. Saipem has been recipient of the first major contracts to install deepwater pre-salt pipelines by national operator Petrobras. Claudio Paschoa, Maritime Reporter’s correspondent in Brazil brings us an in-depth look at Saipem’s vessels and projects in Brazil.

Saipem’s pipelaying segment is part of a unified Business Unit Engineering & Construction, an entity with more than 30,000 employees from more than 100 nationalities, with more than 60 permanent establishments and numerous project execution centers worldwide, which has maintained yearly revenues exceeding $13 billion.

Saipem is capable of developing projects from feasibility and conceptual studies to complex integrated solutions combining design, engineering, procurement, field construction, fabrication and offshore installation and ancillary services such as revamps, upgrading, maintenance, decommissioning, reclamations and decontaminations in virtually every world market. Often this is in remote locations with harsh environmental conditions and challenging logistics, through its proven experience across significant sectors of the oil and gas industry, such as deepwater O&G transportation via offshore pipeline systems. Saipem’s fleet of about 40 offshore construction vessels undertake large offshore and subsea installation tasks worldwide, performed either within major complex EPIC projects or as stand alone T&I contracts. “2014 will be a transition year in which a significant proportion of Engineering & Construction activities will stem from low-margin legacy contracts,” said Saipem CEO, Umberto Vergine. In the pipe layer segment, one of Saipem’s main vessels is the Saipem FDS (Field Development Ship), a special purpose vessel used in the development of deepwater fields, equipped with a dynamic positioning system, a crane with a 600 ton lifting capacity and a vertical pipelaying system capable of operating in water depths of up to 2,000 m (6,561 ft). Deep and ultra-deepwater projects can be tackled by using the J-lay technology on the almost vertical towers of the powerful FDS, FDS2 and Saipem 7000, and by the steep lay of the new company flagship MV Castorone. Saipem maintains that with the J-lay technology they have available even the depth of the Mariana Trench could be reached or exceeded, with the limit only resting in the line pipe resistance. Looking at the future, Saipem has been strengthening its fleet by completing the construction of a new state-of-the-art vessel in 2012, the MV Castorone, a deepwater pipelaying vessel for high productivity operations in extreme environments. The extraordinary growth of the world subsea market over the past decade and the rising demand for O&G plays in deep and ultra-deep waters to begin production and for the deep and ultra-deep water drilling to continue in Brazil, the Gulf of Mexico and in West Africa, has led to the development of a range of new offshore field development and support vessels, including this large new pipelay vessel, currently laying pipelines along the GoM.

Saipem has been present in Brazil since 1987, and. Saipem do Brasil, founded in 2002, has become one of the leading companies in the Oil and Gas sector in the country. According to a Petrobras Engineer directly involved in pre-salt O&G transportation projects, who asked to remain anonymous, “Saipem was chosen for these projects due to their track record in deepwater projects and their investment in state-of-the-art vessels that are perfect for our deepwater pipeline installation needs. Another major factor weighing in their favor was their willingness to build a yard in Brazil and therefore increase the level on local content in their projects.” The integration of the Engineering and Projects Center, the company base located in Rio de Janeiro, with the Offshore Construction Technology Center being built in Guarujá (CTCO), and the use of modern deepwater capable vessels offered Petrobras unique advantages and features.

Saipem FDS

The Saipem FDS mobilized to offshore Brazil in late 2009. The FDS undertook the installation of the Uruguá to Mexilhao gas trunkline. Stretching more than 170 km (105 miles), this 18-inch gas export line represented Saipem’s first major trunkline work in Brazil in many years. The Saipem FDS had previously been a mainstay of the West African offshore construction market. The relocation of this vessel highlights the enormous potential seen offshore Brazil. The vessel is currently working on a project connected to the P-55 production platform at the Roncador field in the Campos Basin, around 120 km (74.5 miles) off the city of Arraial do Cabo, in Rio de Janeiro. Development of the deepwater Roncador field is considered to be one of the most challenging projects from the technological and dimensional points of view, given the depth of the water, which ranges from 1,500 - 2,000 m (4,950 - 6,600 ft.), the size of the field, which is 111 sq. km (43 sq. mi.) and the characteristics of the hydrocarbons, which are located among high quality siliciclastic rock from the Cretaceous age with average porosities of 25% and average absolute permeability of 800 mD. The field is divided into two great blocks separated by an expressive normal fault, with oil gravity varying from 18 - 22º API in Footwall Block and 28 - 30 ºAPI in Hanging wall Block. For development purposes the field is divided in four modules. Preparatory work began in the second half of 2010, while underwater installation operations began in the second half of 2012. Vergine said Saipem has invested heavily to make these new deals in Brazil possible. “Let’s look at Brazil. A closed market where the discovery of big offshore oil fields has created huge perspectives. To enter that market we first closed small deals and now we’re negotiating on a completely different basis.”

Since 2012, Saipem has been operating the MV Castorone, a pipelay vessel with an overall length of 330 m (1,082 ft), excluding stinger and DP 3 capable. The Castorone was classed by ABS and is also Ice classed, capable of berthing 700.

The Castorone is currently the largest PLSV at sea and is officially classed as a PCV (Pipelay Crane Vessel). It was designed to transit at speeds of up to 13 knots, allowing it to reduce the downtime, usually caused by long transits. The Castorone can remotely prefabricate pipe strings 36m long and is capable of laying up to 60” pipes in S-lay mode or up to 36m pipes, with the capability of joining two 18 m pipes as an alternative to the 3 by 12 m conventional joints, in J-lay mode. With her unique J-lay tower capacity of 2,500 tons installed, Castorone can deploy pipelines and trunklines in water depth down to 3,000 m (9,842 ft.). The stinger is specifically designed for any pipe diameter and water depth through continuous control of the overbend stresses on the pipe. The MV Castorone is currently contracted for three projects at the GoM. Following completion of that work, the MV Castorone will move to the Santos Basin in Brazil and join the Saipem FDS 2 in laying Petrobras’ 380 km (236 mile) Lula NE to Cabiúnas trunkline to the coast of Rio de Janeiro, in depths of up to 2,230 meters (7.316 ft.). It will be the first major trunkline connecting Brazil’s offshore pre-salt plays to the coast.

The Saipem FDS 2 vessel already has an EPIC contract for the Guara & Lula-Northeast gas export pipelines in the Santos Basin approximately 260 km (161 miles) off the coast of the Rio de Janeiro, in water depths between 2,100 - 2,200 m (6,889 - 7,217 ft). The contract encompasses the transportation, installation and pre-commissioning of two export pipelines, as well as the engineering, procurement and construction of related subsea equipment: the first 18-inch line will be 54 km (33.5 miles) long and will connect the Guara’s FPSO to a subsea gathering manifold in the Lula field; the second 18-inch line, will be 22 km (13.6 miles) long and will connect the Lula-Northeast FPSO to the same manifold in the Lula field. Saipem has also been awarded an EPCI contract by Petrobras for the Sapinhoá Norte and Iracema Sul Project, to be developed in the Santos Basin pre-salt, approximately 300 km (186 miles) off the coasts of the Rio de Janeiro, in this project the scope of work includes engineering, procurement, fabrication and installation of two offshore pipelines, with related terminations (PLETs) to be installed in the Sapinhoá Norte and Iracema Sul fields in water depths up to 2,200 m (7,217 ft.), along with engineering, procurement, fabrication, installation and pre-commissioning of the SLWR (Steel Lazy Wave Riser) for the collection system at the Sapinhoá Norte field, and of the FSHR (Free Standing Hybrid Risers) for the gas export systems at the Sapinhoá Norte and Cernambi fields. The work will be done by the Saipem FDS 2 vessel, in the fourth quarter of 2014. The FDS 2 is currently working off the coast of Cape Town, South Africa.

In October 2011 Saipem agreed on the acquisition of 100% of TPG (Terminal Portuário de Guarujá S.A.), a company, which fully owns, as a perpetual concession, an area of 35 hectares in Guarujá, within the industrial hub of the Santos Port, the largest port of South America, in the state of São Paulo. The area is strategically located, approximately 350 km (217 miles) from the Santos Basin, where the largest ultra-deepwater pre-salt fields have been discovered and where some plays are already being developed, and approximately 650 km (404 miles) from the Campos Basin, currently the most important Brazilian offshore oil basin, where over 80% of Brazil’s oil is produced. Saipem will develop the area through the construction of a fabrication yard for subsea and floating structures and a logistics base. In the new yard, Saipem will carry out activities which are complementary to the services provided by the highly specialized ultra-deep water fleet recently built by the company.

The yard’s activities will help satisfy the ambitious Brazilian local content requirements in the high-tech industry of ultra-deepwater subsea development. Saipem’s new yard in Guarujá, São Paulo, currently under construction, will be used for pipe logistics and storage for the MV CastorOne, Saipem FDS and the Saipem FDS 2.

Saipem Finances

2013 (restated in accordance with CONSOB indications)

Revenues: €12,256 million

EBIT: €147 million

Net profit: - €159 million

2013 (pro-forma consistent with 2013 reporting)*

Revenues: €12,011 million

EBIT: - €98 million

Net profit: - €404 million

Investments: €908 million

(€1,015 million in 2012)

Net debt: €4,707 million

(€4,278 million at 12/31/2012)

New contracts: €10,653 million (€13,391 million in 2012)

Backlog: €17,514** million

at 12/31/13)

(€19,739 million at 12/31/2012)

New contracts awarded in January and February 2014: € 800 million

Guidance for 2014

Revenues: €12.5 to €13.6 billion

EBIT: €600 to €750 million

Net profit: €280 to €380 million

Investments: approx €750 million

* Data “consistent with 2013 reporting” do not include the effects of Consob restatement.

** Excluded from backlog: €72 million for Perro Negro 6, €795 million for FPSO Firenze.

(As published in the April 2014 edition of Maritime Reporter & Engineering News - http://magazines.marinelink.com/Magazines/MaritimeReporter)

Read Saipem: A Fleet Grows in Brazil in Pdf, Flash or Html5 edition of April 2014 Maritime Reporter

Other stories from April 2014 issue

Content

- Offshore: Seacor Raises the Bar Again page: 13

- Offshore Service Vessels Design Innovation page: 14

- U.S. Coast Guard Doing Less with Less page: 18

- New Conept Under Test: Arctic Drillship page: 20

- If You Have DPS Questions ... OSVDPA Has Answers page: 22

- How to Work with Your Insurer When Experiencing a Loss page: 24

- Calculating Settlement Value of a Case page: 26

- Strategic Planning With Aggregate Data page: 30

- Is Internal Combustion Engine Methane Slip Harmful to the Environment? page: 32

- Floating Production Growth May Face Obstacles page: 38

- Arctic Energy Exploration Efforts Heat Up page: 44

- Saipem: A Fleet Grows in Brazil page: 50

- Inside Paraguay’s Oil Boom page: 54

- The History of Offshore Energy page: 56

- Offshore Energy Timeline:1806-2014 page: 56

- C-MAR's Modern Approach to DP Training in Brazil page: 64

- CNR: Innovation Maintains US Naval Advantages page: 66

- STEM: SeaPerch Underwater Robotic Championships page: 72

- Safety the Focus as Heavy Lifting Picks Up page: 78

- Cool Runnings: R.W. Fernstrum's Engineered Solutions page: 82

- Rosie the Riveter: WWII Women Shipyard Workers Visit the White House page: 88

- Modern Solutions Power Systems Conference page: 91

- ABS Approves Design for GTTNA’s LNG Bunker Barge page: 92

- Rolls-Royce Wins Heyerdahl Award page: 94

- Damen Opens JV Yard in Vietnam page: 95

- BASS Launches New Fleet Management System page: 96

- Shipboard Pipe-joining Techniques Examined page: 98

- Luxury Yachts: Design Takes a New Track page: 100

- New Air Regulator from TDI page: 103

- DNV GL ShipManager for Entire H&P Fleet page: 103

- FARO Debuts X Series Laser Scanner page: 103

- Jinglu Chooses AVEVA Design Software page: 103

- Macro Sensors Gauge Tank Volume Changes page: 103

- Special Coupling Solution for Offshore Drives page: 103

- Conquest Offshore Buys Star Software page: 103

- Eniram Launches New Optimization Product for LNG Sector page: 104

- COSCO Selects Rolls-Royce Package page: 104

- New Tests for Ballast Water Contamination page: 104

- SSI Debuts Updated ShipConstructor page: 104

- Wärtsilä’s Launches Inline Scrubber System page: 104

- New Transas Liquid Cargo Handling Simulator page: 104

- New Hull Structure Analysis Software page: 104

- GEA Westfalia Separator Launches New Control Generation page: 105

- Omega Debuts Compact RTD Temperature Sensors page: 105

- New Heavy Duty CNC Plasma System page: 105

- Wärtsilä Introduces 46DF Dual Fuel Engine page: 105

- WSS Achieves Better Onboard Air Quality page: 105

- Trojan Marinex BWT System Earns IMO Type Approval page: 106