Vessel Operator

-

- Vessel Specific Training Via Adaptive Learning Experience Maritime Reporter, Mar 2013 #34

It is difficult and expensive to do vessel-specific training well. This is probably why, unlike certification training, it is under specified, and in many cases poorly implemented - often via job shadowing. But there is a technology which is an excellent tool for vessel-specific training, and every vessel operator should be aware of it. It is called adaptive learning. This article describes adaptive learning and examines one vessel operator’s deployment of it in order to facilitate vessel-specific training across its fleet of 35 vessels.

Certification training is well defined and regulated by the STCW and the various flag state regulations. Course lists are specified, course curricula are provided and even model courses are available to guide trainers.

However, there is another training component which is arguably just as important, yet it goes largely unregulated and is only minimally specified: vessel-specific training. Broadly speaking, vessel-specific training covers the unique combination of vessel characteristics, layout, equipment, and operating procedures and routines found on a vessel.

It has always been the case that crews needed to be deeply familiar with their vessels in order to operate them safely. But in recent years this need has become much more critical and urgent in light of the continuously increasing sophistication and complexity of modern vessel-based systems. Simply knowing how to operate these sophisticated systems is not sufficient. A deeper understanding is required in order to facilitate intelligent problem solving when the systems are not behaving as expected or, worse yet, when interactions between multiple sophisticated on-board systems produce unpredictable behaviours and outcomes. Crews must be armed with the knowledge necessary to make an informed analysis and arrive at a logical decision. It is the responsibility of each vessel operator to ensure this is so. However, this is much more easily said than done.

The Problem

For vessel operators, delivering standardized, comprehensive training of each vessel’s complex systems and procedures across their fleet can be a daunting task. To illustrate, let’s look at an example.

Consider a vessel operator which manages 50 vessels. These vessels are never uniform. There may be five different types of propulsion systems over the 50 vessels. Bridge equipment is not uniform. Fire fighting systems differ sometimes in their type and manufacturer, and differ always in their layout and implementation. Life rafts differ, marine evacuation systems differ, ship handling differs, and even the route that the vessel is currently operating on can require different reactions to an otherwise similar situation. The fact that each vessel differs from the others in some fundamental way means that the routines and procedures on board can never truly be the same. To further complicate matters, equipment, routines and training practice are all always in flux. So even if a training manual could be written for each vessel, it would be out of date in short order. So how can a vessel operator efficiently create, maintain and continuously improve a standardized, vessel-specific training program when the knowledge requirements vary so much from one vessel to another and changes and updates are an almost continuous necessity?

The answer is that many operators don’t do vessel-specific training particularly well. Instead, they resort to highly imperfect techniques such as job shadowing, sometimes combined with small amounts of classroom-based training. Fortunately, the technique of adaptive learning can provide a solution.

What is Adaptive Learning?

Adaptive learning is a computer-aided training technique designed to tailor each training instance to the needs of the individual trainee.

Although this may sound complex, it can be surprisingly simple and highly effective. In general, adaptive systems “learn” about each trainee and then adapt the learning content and interaction to fit him or her.

How can this be applied to vessel-specific training? The best way to illustrate is to look at how British Columbia Ferry Systems Inc. (BC Ferries) uses adaptive learning to provide vessel- and route-specific training across its 35 vessels serving 47 ports on 25 routes.

Adaptive Learning at BC Ferries

BC Ferries is leveraging adaptive learning across all operational lines of business (Deck, Terminals, Catering, and Engineering).

Taking a deckhand as a specific example at BC Ferries, the actual knowledge required will vary tremendously depending on the vessel and route combination within which the deckhand will be working. Specifically, there are several different types of knowledge required:

● Core knowledge: This is also referred to as “Fleet-generic knowledge” and is the same for all deckhands at BC Ferries. This includes company vision/mission/values, deckhand core competencies, safety, security and environmental policies and information.

● Vessel-specific knowledge: This is the required knowledge pertaining to the vessel that the deckhand will be operating on. It includes equipment on that vessel, procedures unique to that vessel, and so on. It consists of hundreds of pieces of knowledge, the combination of which will be unique to that vessel.

● Route-specific knowledge: This is the required knowledge pertaining to the route the deckhand will be operating on.

● Vessel-Route knowledge: This is knowledge required which is unique to the specific combination of vessel and route that the deckhand will be operating on. For example, operating procedures for the vehicle ramps at the various terminals will often differ based on which vessel is at the terminal.

Obviously for BC Ferries, as for any vessel operator, the creation and maintenance of custom training programs for every possible combination of job position, vessel and route would not be possible as it would number in the many thousands. Even if we took routes out of the equation, the number of distinct training programs required for every combination of job position and vessel would number in the hundreds, rendering their creation and continuous improvement not financially viable.

Instead, BC Ferries uses technology to provide the necessary training resources efficiently through adaptive learning. The trainee experience is now as follows. When an employee begins his or her training, BC Ferries’ learning management system (made by the company I work for) asks the employee to specify three pieces of information:

● What position they are training for,

● What vessel they will be operating on, and

● What route they will be operating on

With the answers to the questions above, the LMS assembles the required knowledge on demand and generates a customized, up-to-date, seamless, and cohesive learning package for that employee, in that position, on that vessel, while operating on that route. The effect is as though someone created, by hand, a learning program specifically targeted for that employee. These learning materials (available online or on paper) are now used to support comprehensive vessel-specific training for that employee at BC Ferries.

The same is true for assessments. When a test is about to be administered, the LMS asks for the position, vessel and route being trained. The examination is then created on demand to address the competencies and knowledge specific to that combination.

The Advantages of Adaptive Learning

For the Learner

The advantages of adaptive learning are reasonably self-evident for the learner. He or she is provided with a learning program which is specifically targeted at the knowledge needed. It is cohesive and seamless and does not require the trainee to judge whether this or that bit of information applies to their position while on their vessel and route. It all applies. More importantly, adaptive learning makes this kind of deep vessel-specific (and route-specific, in this case) training possible where otherwise it would be a practical impossibility.

For the Training Organization

(this is important …)

The advantages to the training organization are possibly even greater. Aside from the greatest benefit of improved training, adaptive learning creates efficiencies in learning content creation and maintenance - the same ones that make vessel-specific training possible. To understand them, a small bit of background is required.

When creating learning materials for an LMS which supports adaptive learning, one “learning module” is created for every “thing” that needs to be trained. For example, if in a fleet of 50 vessels there are three different ECDIS systems, then three modules are created for ECDIS training - one for each different ECDIS system. If four different RADAR units are dispersed across the fleet, then four modules are created for RADAR - one for each unit. This is replicated for the various equipment and procedures which need to be taught. When these modules are entered into the LMS database, they are tagged with the positions, vessels or routes (or any combination of the above) to which they apply. Now, as described above, when a learner specifies their position, vessel and route, the LMS software gathers all the relevant learning modules and, using a “framework”, assembles them into a customized training document which can be delivered to the trainee.

Now perhaps the advantages to the training organization become more clear. First, in a fleet of 50 vessels, it is not necessary to write a separate, complete training program for each vessel. Instead, each procedure or piece of equipment to be trained is documented only once in one small module, and then that module is tagged to indicate which vessels, positions, etc. it applies to. There is no redundant work required.

More importantly, maintenance of the courses is now very manageable. If a vessel has its ECDIS machine swapped out for another, all that is required is the changing of one tag in the LMS database to indicate which ECDIS machine now applies to that vessel. From that point on, training for that vessel will encompass the correct ECDIS machine. Likewise, if the training for one procedure or one class of ECDIS machine is updated to reflect some new information or an improved training approach, only that one learning module needs to be updated, no matter how many vessels or positions that one module is relevant to. From that point on, all trainees in positions or on vessels to which that learning module applies will immediately have the improved training experience. It is in this way that deep vessel-specific training is made possible and practical by an LMS which supports adaptive learning.

The BC Ferries Perspective

Adaptive learning has been an important tool in the implementation of BC Ferries new approach to training called the “Standardized Education and Assessment program”. According to Jeff Joyce, Director of Fleet Operations at BC Ferries:

“The Standardized Education and Assessment (SEA) program is a fundamental safety enabler from both the training and employee engagement perspectives.

Being able to easily tailor programs for each learner ensures relevant, precise and targeted teaching is taking place. This, coupled with equally surgical examination questions and processes ensures that the learner, upon successful completion of the multi-modal clearance process, is fully capable of safely carrying out his or her duties and thereby provides real value to the greater team. Viewed from a different perspective, the Master looking at his or her teams on the bridge and at the mooring stations can be confident that all deckhands who have gone through this program have had equal opportunity to learn all requisite knowledge. The larger team also collectively knows that the SEA graduates have proven to themselves and their shipmates that they have the knowledge (and equally important, the confidence) to proactively participate in all evolutions, be they routine or unforeseen.

The corollary benefit of BC Ferries SEA program, which so ably leverages adaptive learning, is that the maintenance and upkeep of the program is actually completed by the vessel subject matter experts (SMEs), thereby sustaining the engagement of these employees on the deck plates - the SMEs are enabled to keep the material relevant and then reap the rewards of their efforts by working side-by-side with their shipmates who have completed SEA training. This process of quality training material being delivered and maintained by SMEs results in confident, capable graduates. These new teammates frequently become engaged trainers themselves once they’ve honed their knowledge and skills with experience...resulting not only in an almost self-sustaining cycle of training success, but more fundamentally, safer operations and enhanced customer service.”

Conclusion

The advantages of adaptive learning to maritime industry training cannot be overstated. Properly applied, it makes vessel-specific training not only possible, but also highly practical and sustainable where previously it was neither. Given the importance of vessel-specific training in this era of ever increasing complexity of vessel systems and procedures, this technique is one which is critically important now and will only increase in utility and applicability as time marches on.(As published in the March 2013 edition of Maritime Reporter & Engineering News - www.marinelink.com)

-

- Fuel Solutions: Shelter from the Financial Storm Marine News, Mar 2014 #30

Vessel operators seek protection by hedging fuel needs. It’s easier than you might think. Some workboat operators defend themselves against higher diesel prices by buying futures contracts, while others purchase fuel at prices fixed in advance from their suppliers. Others, perhaps less-savvy and/or

-

- gplink: Remote monitoring system designed for CAT engines Marine News, Feb 2013 #37

way that homeowners with home security systems can gain similar leverage with their casualty insurance brokers. gplink’s Geo-Fence feature allows the vessel operator to set up a precise boundary within which the boat should be operating or docked. Any unauthorized movement outside that boundary will prompt

-

- ABB Energy Management System Maritime Reporter, May 2014 #55

vessels and entire fleets. This installation will cover dynamic trim optimization and hull condition monitoring. The package is designed to help the vessel operator to optimize required propulsive power and forecast hull and propeller fouling, with both contributing to reduced fuel consumption. www.abb

-

- Automatic Logging System Developed By NMS— Literature Available Maritime Reporter, Apr 1981 #24

shaft rpm. Data and time are recorded for every control or function. The system is extremely flexible, and any parameters may be selected by the vessel operator. Customization to a specific vessel is said to be easy and economical. The bell logger system is designed for the marine environment, including

-

- Simrad Offers Literature On NL Doppler Speed Log Maritime Reporter, Jul 1978 #46

The NL Speed Log, which offers accurate and reliable speed and distance information to the vessel operator, is described in new literature offered by Simrad, Inc. Ideal as the speed sensor for integrated NAV Systems, the NL outputs in BCD and / or analog format speed, distance, tracking mode and

-

- OP/ED: The Capital Construction Fund Marine News, Mar 2019 #24

How to make the Capital Construction Fund work for all vessel owners and operators.The Red and White Fleet is a passenger vessel operator on San Francisco bay with roots back to 1892. We make no secret of the fact that we want to build new vessels with zero environmental signatures, all in an effort to

-

- Bandwidth Efficiency will Drive Maritime Digitalization Maritime Reporter, Oct 2020 #16

; a convenient feature at home when connected to an unlimited ‘SuperFiber’ broadband package, but not efficient when offshore using satellite. The vessel operator logged into myastportal and via the INTEGRA See service, was able to pinpoint a singular encrypted application which was consuming unusually high

-

- Container Shipping & Perfecting on-time Performance Maritime Reporter, Jul 2020 #54

themselves. AIS feeds, noon reports, arrival and departure notices and other information should be accepted directly into the software allowing the vessel operator to quickly identify if the vessel is running to schedule or deviating from its planned voyage.If a delay is identified, clever software will allow

-

- MarTID 2020: Take the Global Maritime Training Survey Marine News, Feb 2020 #40

response globally, the MarTID steering group again opted to both shorten the survey and to offer three, targeted versions for these three stakeholders:Vessel operator survey: https://www.surveymonkey.com/r/2020MarTIDOperatorMETI survey: https://www.surveymonkey.com/r/2020MarTIDMETISeafarer survey: https://www

-

- Great Ships of 2014: Harvey Energy Maritime Reporter, Dec 2014 #45

In 2011 Harvey Gulf International Marine became the first U.S. vessel operator to contract for construction of vessels by LNG. The first of these vessels to be delivered is the Harvey Energy. In addition to being able to operate on cleaner burning natural gas, the Harvey Energy has “ENVIRO+, Green Passport”

-

- Halter To Build Two Supply Vessels For Jackson Marine Maritime Reporter, Oct 15, 1981 #51

delivery of the 100- foot tug Captain Jac. Since then Halter has built 33 tugs, 13 supply boats, and one crewboat for the Texas-based vessel operator. The new vessels will each be 180 feet long, with a 40-foot beam, and 14-foot depth. Each will be powered by two Caterpillar D-399 engines

-

)

March 2024 - Marine Technology Reporter page: 47

)

March 2024 - Marine Technology Reporter page: 47PRODUCT, PROFESSIONAL, VESSELS, MTR BARGES & REAL ESTATE FOR SALE Marketplace INNOVATIVE. UNIQUE. PROVEN. ALLAMERICANMARINE.com ???????????????????????????????????????? 9??????????SiC A????????ArC????????????????S???????C?????????9???Ç????????? ????????????????Ý???????S???y???????????????????K???:???? MAR

-

)

March 2024 - Marine Technology Reporter page: 44

)

March 2024 - Marine Technology Reporter page: 44. The CL-360 Marine is the only lidar of evaluating and classifying the potential objects of interest. system designed for use on an uncrewed surface vessel (USV) Teledyne Geospatial brought its latest advancements in that provides survey grade range and accuracy. ocean mapping hardware and software solutions

-

)

March 2024 - Marine Technology Reporter page: 43

)

March 2024 - Marine Technology Reporter page: 43EM 124 or EM 304 MBES systems – which is in most cases using the 5430A transmitter. It is fully digital and features a va- already available on board the vessel. Essentially, the EM SBP riety of waveforms unavailable with the previous generation of software “borrows” the EM 124/304 hardware to transmit the

-

)

March 2024 - Marine Technology Reporter page: 35

)

March 2024 - Marine Technology Reporter page: 35buoyancy high and weight low, WHOI’s SeaBED AUV captures the attention of a pair of curious Antarctic penguins as it is deployed from the British research vessel James Clark Ross. Vehicle designers allowed for temperature reduction of battery capacity. Rechargeable batteries may be put on trickle chargers

-

)

March 2024 - Marine Technology Reporter page: 33

)

March 2024 - Marine Technology Reporter page: 33of collectors can be de- ployed concurrently. Once a collector has achieved its 6,000kg payload, it can return to the surface, and as the surface vessel reaches capacity, it can return to shore while the collectors continue to load on a second vessel. There is no sediment release mid-water like

-

)

March 2024 - Marine Technology Reporter page: 32

)

March 2024 - Marine Technology Reporter page: 32study on The company’s SMD Q-Collector range is available in a vari- processing 1.3 million tonnes of wet nodules per year, and the ety of sizes to suit vessel and client requirements. Engineered company is also exploring opportunities for the construction to have a low submerged weight, these vehicles are

-

)

March 2024 - Marine Technology Reporter page: 31

)

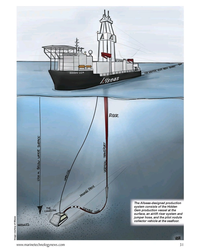

March 2024 - Marine Technology Reporter page: 31The Allseas-designed production system consists of the Hidden Gem production vessel at the surface, an airlift riser system and jumper hose, and the pilot nodule collector vehicle at the sea? oor. Image courtesy of Allseas www.marinetechnologynews.com 31 MTR #3 (18-33).indd 31 4/4/2024 2:12:41

-

)

March 2024 - Marine Technology Reporter page: 30

)

March 2024 - Marine Technology Reporter page: 30MINING bilical. It has passive heave compensation which nulli? es the necott. “The focus since then has been on scaling while en- wave, current and vessel motions that in? uence loads in the suring the lightest environmental impact,” says The Metals power umbilical. The LARS can operate in up to 3

-

)

March 2024 - Marine Technology Reporter page: 29

)

March 2024 - Marine Technology Reporter page: 29has partnered with Allseas which has a con- verted drillship, Hidden Gem, set up for nodule collection. Onboard technology developments include the vessel’s launch and recovery system (LARS) which deploys and recovers the col- lector and feeds its power and control um- www.marinetechnologynews.com 29 MTR

-

)

March 2024 - Marine Technology Reporter page: 25

)

March 2024 - Marine Technology Reporter page: 25InvesO gaO on • Sand Resource InvesO gaO on featured SEA-KIT International’s USV Maxlimer and marked the ? rst time an uncrewed surface vessel had been used to survey the aftermath of subsea volca- nic activity. Controlled remotely from the company’s base 16,000 km away in the Portable

-

)

March 2024 - Marine Technology Reporter page: 19

)

March 2024 - Marine Technology Reporter page: 19tracker is not required, resulting in signi? - Svenn Magen Wigen is a Cathodic Protection and corrosion control cant cost savings, mainly related to vessel charter. expert having worked across The major advantage of using FiGS on any type of subsea engineering, design, modelling, structure is the large

-

)

March 2024 - Marine Technology Reporter page: 18

)

March 2024 - Marine Technology Reporter page: 18higher above the pipeline and still obtain valuable data. The the measurement of protection levels (potential) using non- increased speed saves costly vessel time, while the larger mea- contact sensors. The collected data is then merged with CP surement distance lowers the risks associated with the ? ight

-

)

March 2024 - Marine Technology Reporter page: 13

)

March 2024 - Marine Technology Reporter page: 13nyone familiar with glider hardware options integrated for a broad Glider answers that need,” said Shea autonomous underwater ve- range of missions. Quinn, Slocum Glider Product Line hicles (AUVs) is certainly “As the use of Slocum Gliders grew, Manager at TWR. A familiar with the popular- so did

-

)

March 2024 - Marine Technology Reporter page: 11

)

March 2024 - Marine Technology Reporter page: 11range of sensors to de- focusing on autonomous undersea systems. tect their prey – acoustic, magnetic, pressure – and as such pose a hazard to manned MCM vessels. To safely detect, identify, and classify these mines, AUVs would be deployed from standoff range to scan the seabed using high resolution underwater

-

)

March 2024 - Marine Technology Reporter page: 9

)

March 2024 - Marine Technology Reporter page: 9detection from the air operated vehicle (ROV) that enables standoff EOD from either using manned or unmanned aerial systems (UAS). And because a surface vessel or helicopter. Archer? sh, from BAE Systems, they are adrift, these mines are also challenging to neutralize. is a similar system deployed from

-

)

March 2024 - Marine Technology Reporter page: 8

)

March 2024 - Marine Technology Reporter page: 8by tually, and this threat will need to be fully neutralized to en- extension the global food supply. sure safe passage not only for commercial and naval vessels, Although reports indicate that Soviet-era moored contact but for the scores of ? shing and recreational vessels operating 8 March/April 2024 MTR

-

)

April 2024 - Maritime Reporter and Engineering News page: 48

)

April 2024 - Maritime Reporter and Engineering News page: 48Technology Group Limited, 7 Turner Avenue, Falmouth Scientific, Inc., PO Box 326, Pocasset, MA , Technology Park Bentley WA 6102, Australia , tel:61 VESSEL BUILDING: RESEARCH, USA , tel:(508) 564-7640, [email protected] contact: 429498089, [email protected] Fred Hegg, Falmouth.com PASSENGER

-

)

April 2024 - Maritime Reporter and Engineering News page: 47

)

April 2024 - Maritime Reporter and Engineering News page: 47grow your business globally. (877) 534-6445 your copy online or www.wilkesandmclean.com in print today! [email protected] WWW.INTELATUS.COM Vessels, Barges & Real Estate for Sale/Rent w?uO?ÐuA?Ž?wIGAl??GEÐŽYlGYlÐAÐUAOG s?AO?GAl?A?lŽd?suld?AYEA?A?GYG??lŽ lSGsYE??l????uA?OG?l|G

-

)

April 2024 - Maritime Reporter and Engineering News page: 43

)

April 2024 - Maritime Reporter and Engineering News page: 43outline reform CII until a better understanding Transportation" panel session covering of standards for secure data exchange, of the impact of changing vessel speeds how to reduce shipping’s carbon foot- vendor neutrality and data property pro- is established. www.marinelink.com 43 MR #4 (34-44).indd

-

)

April 2024 - Maritime Reporter and Engineering News page: 41

)

April 2024 - Maritime Reporter and Engineering News page: 41GMDSS/NAVTEX/NAVDAT coastal surveillance and transmission systems • Offshore NDB non-directional radio beacon systems for oil platform, support vessel & wind farm applications • DGPS coastal differential global positioning systems • VHF port communication systems Nautel and Kenta bring 55+ year

-

)

April 2024 - Maritime Reporter and Engineering News page: 40

)

April 2024 - Maritime Reporter and Engineering News page: 40function combines images from day and from different systems to understand the objects they see on night cameras. The result is a clear view of the vessel surround- the screen and how they correlate with where they are in the ings even during night-time operations or other low-visibility real world

-

)

April 2024 - Maritime Reporter and Engineering News page: 39

)

April 2024 - Maritime Reporter and Engineering News page: 39labor costs and scaffolding costs. Norway OKs Ammonia Bunkering Terminal The Norwegian Directorate for Civil Protection gave its ap- shore supply vessels that regularly call at Fjord Base in Florø. proval to the construction of the planned ammonia bunkering The planned terminal is part of Yara Clean

-

)

April 2024 - Maritime Reporter and Engineering News page: 38

)

April 2024 - Maritime Reporter and Engineering News page: 38its electric line handling tug Castalia, Consulmar towed tion for mooring operations. In addition to mooring, the mul- the steel mooring lines from the vessel to each of the ? ve moor- tipurpose Castalia, which measures 12.5 x 5 m, plays a role in ing buoys. various port activities, including collecting

-

)

April 2024 - Maritime Reporter and Engineering News page: 37

)

April 2024 - Maritime Reporter and Engineering News page: 37SIMULATION "A simulated vessel ? ooding can help teams work together to solve the challenge using different systems on the bridge." – Jussi Siltanen, Lead, "The gami? cation of Product Marketing, learning makes it fun." Safety Solutions at NAPA – Captain Pradeep Chawla, Founder, MarinePALS Image