Naval Architect

-

- A Naval Architect's Look At Design Trends Maritime Reporter, Jun 2002 #24

Reading tea leaves on a boat underway is an exercise in frustration because just as the leaves start to settle, another wave comes along and changes the picture.

Similarly, trying to foresee trends in the marine industry. Just as you see things shaping up, a change occurs and the industry is re-shujfled. However I believe that I can discuss three particular trends that are part of our collective future.

Regulations The first of these is the fact that the marine industry will continue to see a growing body of regulations affecting how we design, build, and operate vessels.

Some examples of the alphabet soup that we must deal with include ADA, STCW, ISM, EPA, etc. These regulations are being created by organizations both within and outside of the marine industry. Many marine regulators such as the U.S. Coast Guard are increasingly relying upon other bodies such as the American National Standards Institute (ANSI), National Fire Protection Association (NFPA), and American Society for Testing of Materials (ASTM). Their purpose in doing so is to try and keep the regulations more current. However, this also can mean that the regulations are getting further away from our industry.

We have also seen a shift from prescriptive regulations to performancebased regulations. What does this mean to the industry? Let's look at some examples: • Prescriptive Regulation — "Each compartment must have two means of escape, one of which must be a pathway or ladder meeting regulation ABC, the other way be a vertical ladder on horizontal egress via a designated widow with minimum dimensions of X by Y." • Performance Based Regulation — "Demonstrate that there is a safe egress path from each compartment given the following hazard scenarios: fire, flooding, extreme heel and trim." The prescriptive regulation is more objective. It's easier to measure compliance.

The performance based regulation is more flexible but requires more effort by all parties (designer/builder/operator/ regulator). We have seen that both the U.S. Coast Guard and the International Maritime Organization (IMO) are increasingly working on risk-based approaches to regulations, which are clearly performance based. By introducing the notions of risk and associated consequences, the regulations are potentially more rational and objective. I fear however that the cost of demonstrating compliance to such risk based regulations will be expensive.

Increase in sophistication of systems The second trend that I see is the increasing sophistication of systems and equipment onboard vessels. Perhaps our future vessels will be "smart" with voice-activated systems, integrated command, control, and communication, and self-checking equipment to facilitate maintenance and improve reliability.

We are already seeing smart equipment as shown by two examples.

• Electronic combustion controls on diesel engines — improve power, reduce emissions, adapts to load/mission profiles.

• HVAC systems — Self adjusts to reflect time of day, season, handles dif- ferent latent and sensible heat loads, varies air volumes to suit occupancy.

Every technology has its flip side, however,. "Smart" equipment needs to be programmed just as your VCR needs to be programmed to record programs.

Just because you can program your VCR to receive TV programs two months in advance on alternate Tuesdays, how many of us need or want that capability?

Who remembers how to reprogram them when the power fails? We see the same challenges in these new sophisticated systems. As a firm, Elliott Bay Design Group has had to help customers with: • Programmable electronic circuit breakers that trip off-line for no apparent reason.

False readings from sensor affected by radio frequency interference from power circuits or from voltage spikes.

• Elevator controls where a loss of power causes the system to re-boot with a consequent loss of programming.

As an industry we need to carefully consider the benefits and potential problems that come with modern technology- Vessel Affordability The third trend is a little harder to define but is no less real. I believe that U.S. ship owners and shipyards will increase working together to make vessels more affordable. This means that the ship owners must become more knowledgeable about construction practices.

They need to understand the balance between labor costs and materials costs, the impact of scheduling on labor productivity, and how contract provisions such as quality standards can impact the shipyard overhead. For example, bulkheads and decks can be stiffened by bulb flats instead of angles.

The material cost is higher but coating systems are easier to apply so the coatings last longer. A proactive owner will understand the life cycle cost benefits that result from different construction techniques.

Smart owners will ask their designer and/or builder about where the dollars are in the vessel. Sometimes spending more money on a piece of equipment that is easier to install can result in a net saving. Does the yard have preferred suppliers for doors, electrical equipment, valves, etc.? Why do they prefer them and is there a savings to the customer?

Is the yard's standard detail for a handrail acceptable rather than the designer's approach? I think lhat more owners will ask questions and conduct a dialogue with the shipyards. Everyone will benefit.

The U.S. shipbuilding industry will also work smarter, not harder. On a recent contract for a fishing vessel we compared an overseas yard that could build the vessel with 40,000 labor hours vs. a U.S. yard that required 50,000 labor hours. This kind of gap will be closed as U.S. yards spend more effort on improving their production practices and the associated planning. For example: I recently visited a yard where they traditionally spent 60 labor hours to fit a bow wrapper plate with come-alongs, wedges, and trimming excess from the plate. After learning about line-heating methods they were able to fit a similar plate within 12 labor hours. The plate was cut neat and treated with line heating to take a numerically predicted shape.

Successful shipyards will adopt some new technologies and processes.

Technologies will include line heating, statistical accuracy control, 3-D product modeling, and product work breakdown structures. New processes will include a detailed build strategy, increased use of shipyard standards and specific vendor equipment, better control of schedule and material flow, and zone-by-stage construction.

At a recent meeting of the Passenger Vessel Association Sen. Trent Lott, (R-Miss.), expressed his opinion that the U.S. could be competitive in shipbuilding. We will do so if we continuously seek to improve our shipbuilding processes, benchmark ourselves against our international competitors and train our work forces to use the tools we have.

There you have my three trends. I think that they apply to all market sectors of the diverse and interesting marine industry. A common theme among them is communicating information and asking questions. At a seminar on regulations a speaker said, "You're either a player or a victim." Let's all be players and work together.

-

- Sun Ship Names Schmitt Naval Architect Administrative Division Maritime Reporter, May 15, 1977 #49

Sun Shipbuilding and Dry Dock Co., Chester, Pa., has appointed Richard Schmitt as naval architect, Shipbuilding Administrative Division. Mr. Schmitt's responsibilities include the review and updating of ship repair cost estimating techniques and the development of special marketing programs. He

-

- Bethlehem Steel Shipbuilding Names Roland V. Danielson —Hollinshead De Luce Retires Maritime Reporter, Sep 15, 1977 #26

. Mr. de Luce is completing 38 years of service with Bethlehem Steel. A native of Bayville, N.Y., he was graduated from Webb Institute of Naval Architecture and began his career with Federal Shipbuilding and Dry Dock Company, and then Fairbanks, Morse & Company. He joined Bethlehem in 1939 in

-

- Bethlehem Steel Names Thomas Robinson To Central Technical Post Maritime Reporter, Oct 1977 #14

and repair yards. A native of Quincy, Mass., Mr. Robinson is a 1943 graduate of the University of Michigan, with a B.S. degree in naval architecture and marine engineering. He joined Bethlehem at the Fairfield Yard as a draftsman in 1943, and following two years in the Navy at the Office

-

- James Sweat Joins Matzer Associates Maritime Reporter, Sep 15, 1978 #49

James C. Sweat, naval architect, has joined Rudolph F. Matzer and Associates of Jacksonville, Fla., according to Rodney E. Lay, president of the internationally known firm of naval architects and marine engineers. Mr. Sweat comes to Matzer Associates with experience in the design and engineering of

-

- I.C. Kizilkaya And John Slager Have Joined Designers & Planners, Inc. Maritime Reporter, Aug 1980 #53

as director, hydrodynamics design. The announcement was made recently by Ferd Serim, president of the company. Designers & Planners is a firm of naval architects and marine engineers with offices in New York, Washington, and Galveston. Mr. Kizilkaya will be responsible for the management of all technical

-

- Elliott Bay Design and Bauer Interiors Create A "Prince" Maritime Reporter, Feb 2002 #31

When a naval architect and interior designer sit down to design a commercial vessel, they must blend together a multitude of considerations that delicately balance form and function. The naval architect's job is to ensure that the vessel meets a variety of government safety regulations and marine

-

- No. California SNAME Discusses Ships And Terminals For Nodules Mined From Deep Pacific Ocean Maritime Reporter, Jul 15, 1978 #33

Benjamin Van Cleve Andrews, naval architect, presented a paper entitled "Transport Ships and Marine Terminals for Manganese Nodules Mined from the Deep Pacific Ocean," at a recent dinner meeting of the Northern California Section of The Society of Naval Architects and Marine Engineers, held at the

-

- SNAME Announces Standing Special And Technical Committees For 1986 Maritime Reporter, Jun 1986 #84

Capt. Perry W. Nelson, USN (Ret.), president of the Society of Naval Architects and Marine Engineers, a professional/technical organization for members of the mar rine industry, announced the following committee chairmen for 1986: STANDING AND SPECIAL COMMITTEES Advisory Public Service Committee— Do

-

- FORAN Takes a Run at North America Marine News, Oct 2014 #24

market]. Military Maneuvers “There aren’t that many military contracts out there, and it can take years to get out a bid,” cautioned one veteran naval architect, who asked not to be named. “They’ll have to convince a shipyard or naval architects doing the design, and the naval architect firm won’t do it

-

- Case Study: C-Job & Accelerated Concept Design Maritime Reporter, Oct 2018 #78

C-Job Naval Architects has implemented a new method to optimize ship designs. The holistic optimization method allows for quick design iterations, exciting innovations and saves the naval architect a significant amount of time.C-Job Naval Architects is the largest independent ship design and engineering

-

- Suehrstedt Appointed President Of Marine Consultants & Designers— Plude Named Vice President Maritime Reporter, Mar 1985 #6

as vice president of the firm. Mr. Suehrstedt has been employed by the company since 1951. He became vice president in 1972 after serving as chief naval architect since 1959. Mr. Tripp had been president of the firm for the past 25 years. Mr. Plude joined MC&D in 1958 as naval architect, and has been

-

)

April 2025 - Maritime Reporter and Engineering News page: 10

)

April 2025 - Maritime Reporter and Engineering News page: 10, com- support operations in the North Sea. The company selected Salt pleting the project in 2020-2021. Building on this, the com- Ship Design as the naval architect and ZPMC shipyard in China pany later won a contract to operate three CTVs for ongoing to construct the vessels. “We’re not newcomers to this

-

)

March 2025 - Marine Technology Reporter page: 27

)

March 2025 - Marine Technology Reporter page: 27has also been expanded, a decision in- CCRV began with planning and collab- ? uenced by the vessel’s future-proo? ng oration among leading naval architects, efforts. Initially designed to run on a regulatory bodies, and industry partners. combination of liquid hydrogen and die- “We selected Glosten

-

)

October 2024 - Marine News page: 38

)

October 2024 - Marine News page: 38Corporation and Su- derman & Young Towing Company—said the new high horsepower, highly maneuverable RApport 2800 tug- boats have been designed by naval architect Robert Allan Ltd. speci? cally for the Port Arthur LNG export facility. The new 92- by 40-foot tugs feature a compact design providing increased

-

)

September 2024 - Maritime Reporter and Engineering News page: 30

)

September 2024 - Maritime Reporter and Engineering News page: 30the advancement of technology in that rapid advance- ment has really pushed us to take on more expertise and grow from simple marine engineering and naval architecture.” But even with the rapid pace of technology and growth, Glo- sten remain ? rmly rooted with a focus on safety, reliability, and ef? ciency

-

)

August 2024 - Marine News page: 10

)

August 2024 - Marine News page: 10Insights Morgan Fanberg, Robert Ekse, Wade Carson, CEO, Glosten President, Elliott Bay Design Group CEO, Vard Marine Roundtable: North American Naval Architects Weigh In arine News spoke to leaders at three North and evaluate concepts, and to synthesize large data sets to American naval architecture

-

)

June 2024 - Maritime Reporter and Engineering News page: 41

)

June 2024 - Maritime Reporter and Engineering News page: 41optimal HVAC system installation are met. The Author The Author King Matz Brian King joined EBDG in 1988 and in his last full- Mr. Drew Matz is a Naval Architect for Elliott Bay time position was President - Chief Engineer until Design Group specializing in vessel stability, com- retirement in May 2021

-

)

June 2024 - Maritime Reporter and Engineering News page: 38

)

June 2024 - Maritime Reporter and Engineering News page: 38FEATURE UTILIZING CFD ANALYSIS TO OPTIMIZE VESSEL VENTILATION All images courtesy EBDG By Brian King, PE, Principal Emeritus, and Drew Matz, PE, Naval Architect hen envisioning the future of vessel design, fow characteristics throughout the entire volume. Using this considerations for heating, ventilation

-

)

June 2024 - Maritime Reporter and Engineering News page: 4

)

June 2024 - Maritime Reporter and Engineering News page: 4and in his last full-time position Matz Email: mrcirc@marinelink.com neering News since 2013, and was President - Chief Engineer Drew Matz is a Naval Architect Web: www.marinelink.com was previously managing editor until retirement in May 2021. for Elliott Bay Design Group t: (212) 477-6700 of

-

)

May 2024 - Maritime Reporter and Engineering News page: 33

)

May 2024 - Maritime Reporter and Engineering News page: 33Robbery Group, as If you could offer one bit of advice well as a number of Vice-Chair and Board member roles. to shipowners regarding making A naval architect at heart and by training, Mr. Dominguez gained his ? rst degree at Veracruzana University, Mexico, and their operations more ef? cient, later

-

)

April 2024 - Maritime Reporter and Engineering News page: 31

)

April 2024 - Maritime Reporter and Engineering News page: 31newbuilding currently being built in China. Details of this vessel’s lifting capacity are yet to be made public, but Jesper Kanstrup, Senior Naval Architect at KNUD E. HANSEN, says these big cranes and vessels are needed to meet the installation challenges of scaling up of turbine ca- pacity to 20MW

-

)

April 2024 - Marine News page: 42

)

April 2024 - Marine News page: 42Mariacher, Soares Bristol Harbor Group, Inc. an- Port Houston has promoted nounced it has hired Kyle Pagan as Ryan Mariacher to chief port op- a naval architect. erations of? cer and Paulo Soares to chief port maintenance of? cer. TVIB Promotes Hunsaker Cindy Hunsaker has been pro- moted to Instructional

-

)

February 2024 - Maritime Reporter and Engineering News page: 38

)

February 2024 - Maritime Reporter and Engineering News page: 38receiving a new series of 25 LNG dual-fueled tions' when talk turns to decarbonizing the maritime sector and containerships, as Seb Brindley, Senior Naval Architect, Sea- ammonia certainly has its drawbacks, led by the caustic nature span Ship Management, explains. “We need to be ready for of the fuel itself

-

)

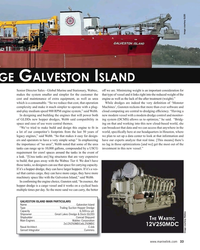

December 2023 - Maritime Reporter and Engineering News page: 33

)

December 2023 - Maritime Reporter and Engineering News page: 33Great Lakes Dredge & Dock (GLDD) Shipbuilder Conrad Shipyard T W HE ABTEC Main Engines Wabtec Corporation 2x12V250MDCx6L250MDC 12V250MDC Naval Architect C-Job Genset Integrator Cummins Image courtesy Wabtec www.marinelink.com 33 MR #12 (18-33).indd 33 12/5/2023 12:39:26 P

-

)

September 2023 - Marine Technology Reporter page: 51

)

September 2023 - Marine Technology Reporter page: 51software can Marblehead, MA. Founded in 2017 by provide situational awareness to remote be used to program and execute mis- two MIT trained naval architect/serial operations centers and enable effective sions while monitoring the status and entrepreneurs who spotted an opportu- remote piloting

-

)

September 2023 - Maritime Reporter and Engineering News page: 15

)

September 2023 - Maritime Reporter and Engineering News page: 15that every governing equation—whether it be Marlantes related to ? uid ? ow, structural deformation, or dynamics— Kyle E. Marlantes is a naval architect, software could be decomposed into two parts: a low-cost, low-? delity developer, and PhD candidate at the Univer- part, and then a high-cost

-

)

August 2023 - Maritime Reporter and Engineering News page: 15

)

August 2023 - Maritime Reporter and Engineering News page: 15, even if adequate training data are attainable, if efforts to Marlantes obtain the data address the original prob- Kyle E. Marlantes is a naval architect, software developer, and PhD candidate at the University of Michigan, where lem directly, then a resulting AI is ren- he develops methods to

-

)

August 2023 - Maritime Reporter and Engineering News page: 13

)

August 2023 - Maritime Reporter and Engineering News page: 13a keelboat. Then there is the hull speed equation for slender hulls. The standard equation for hull speed in knots is familiar to just about every naval architect: Hull speed = 1.34 x Square Root (L) Where L is the waterline length in feet. However, for slender hulls I have seen hull speed de? ned as: Slender

-

)

August 2023 - Marine News page: 44

)

August 2023 - Marine News page: 44he takes on the president title. Bristol Harbor Group, Inc. an- nounced the continued expansion of its Doyle Returns to Lead DCA ? rm with two new naval architect hires: William P. Doyle has returned to lead Taylor Althouse and Kasey Kennedy. Armstrong Hume the Dredging Contractors of America as CEO

-

)

December 2022 - Maritime Reporter and Engineering News page: 21

)

December 2022 - Maritime Reporter and Engineering News page: 21the French Minis- On one level, Blue? ns is a singular start-up, the brainchild try of Agriculture and Food. Its vision is to advance science, of a naval architect and a mechanical engineer with a com- expertise and innovation in three broad areas: bined 40 years of maritime experience. On another level,

-

)

November 2022 - Marine Technology Reporter page: 21

)

November 2022 - Marine Technology Reporter page: 21built wooden sailing vessels On one level, Blue? ns is a singular start-up, the brainchild of Bto post-graduate oceanic research and training. a naval architect and a mechanical engineer with a combined The opportunity to attend Sea Tech included an invitation to 40 years of maritime experience. On another

-

)

November 2022 - Marine News page: 73

)

November 2022 - Marine News page: 73for the ? rm’s Federal Programs as Vice President of Sales USA. national business line. Marine Travelift Harris Joins Foreship TSCG Hires Hentschel Naval architecture and marine en- Promotes Minten Ryan Hentschel has joined naval ar- The Marine Travelift/Shuttlelift/Ex- gineering consultancy Foreship ap- acTech

-

)

September 2022 - Marine Technology Reporter page: 10

)

September 2022 - Marine Technology Reporter page: 10operations. But AI will also is also equipped with ? ve cameras for play a role, says Rafael, for things like stereoscopic SLAM-based navigation naval architect and a robotics special- ist, it launched its ? rst USV, the 4.95 spotting blade defects. and photo & video capture for real- For using a larger

-

)

October 2022 - Marine News page: 46

)

October 2022 - Marine News page: 46Marine Design Boksa Marine Design duction engineering projects for Conrad Shipyard, Blount B M DOKSA ARINE ESIGN Boksa Marine Design (BMD) is a naval architecture Boats, St. Johns Ship Building, VanEnkevort Tug & Barge and Overseas Shipholding Group. BMD recently provided and marine design ? rm located

-

)

October 2022 - Marine News page: 44

)

October 2022 - Marine News page: 44patrol boat and workboats. Enabling people to get a smaller workboat, but the 85’ Mk VI patrol boat. In addition to its “standard” also have a real naval architect and engineer go through it— cadre of SAFE Boats, the builder has established partner- give them renderings, give them that tailored experience