Environmental Engineering

-

- Answering the Call for Environmental Answers Marine News, Sep 2018 #50

The Coast Guard has developed two separate mitigation system prototypes specifically designed for inland and offshore environments and tested them in the Kalamazoo River and Lake Huron.

Whenever there is a need for oil, there will always be a risk of oil spills. This is no less true for bituminous sands, commonly known as oil sands or tar sands. Oil sands are mostly found in Alberta, Canada, and comprised of bitumen, sand, clay and water. They are typically viscous, with a texture similar to peanut butter. Alberta’s oil companies transport their product to coastal refineries outside of landlocked Alberta. One method of transport involves adding diluents, such as natural gas condensates, to oil sands to reduce viscosity and make transportation by rail or pipeline easier. The new product blend is called diluted bitumen, or dilbit.

Today, scientists and researchers continue to study dilbit’s properties as well as its fate and behavior if spilled into the environment. Dilbit’s characteristics are similar to that of crude oil, but real world experience demonstrates that it behaves differently during a spill incident. In 2010, approximately 877,000 to 1 million gallons of dilbit flowed into the Kalamazoo River from a burst pipeline. Over 20 miles of shoreline were affected, making it one of the largest inland oil spills in U.S. history. Responders faced the atypical challenge of trying to mitigate the impacts of moving, sunken oil. The U.S. Environmental Protection Agency (EPA) On-Scene Coordinators and Oil Spill Removal Organizations (OSROs) tried several approaches to recovering the moving, sunken oil with varying degrees of success. It was evident that a better mitigation approach was needed not only for oil spills in rivers and streams, but for other potential dilbit or non-floating oil spills in the nearshore and large lake environments.

- Finding a Better Way

In 2016, the U.S. Coast Guard Research and Development Center (RDC) took on this challenge and began projects to identify, design, and test new methods for responding to non-floating oil spills, including detection and removal of sunken oil on the bottom and suspended in the water column. With funding support from the EPA through its Great Lakes Restoration Initiative (GLRI) program, the Coast Guard developed two separate mitigation system prototypes specifically designed for inland and offshore environments and tested them in the Kalamazoo River and Lake Huron, respectively.

The inland mitigation system prototype was test deployed in the upstream portion of Morrow Lake in Kalamazoo, Michigan, in April 2018. This location was selected due to its proximity to the Great Lakes where GLRI stakeholders would have an opportunity to observe the equipment and ask questions of the project team. Lake Huron was selected as the test site for the offshore mitigation system prototype for the same reason.

The inland mitigation system prototype includes a 75-foot barrier that consists of three separate 25-foot segments connected to each other. It was designed to deflect moving, sunken oil toward the shoreline, for use in fast waters with a current up to 3 to 4 knots. This design is intended to allow an easier recovery of sunken oil since it would be diverted to an area with minimal current. Two segments of the barrier (total of 50 feet) are 3 feet high with the last segment (25 feet) nearest the shoreline measuring 2 feet high to account for the decreasing water depth and lower current. The angle of barrier deployment (or angle of deflection) relative to the shoreline is dependent on the river current; the higher the current, the less the angle. This ensures that the barrier’s fabric material is not exposed to damaging levels of pressure exerted by the river current.

The barrier itself is comprised of X-Tex fabric and high-density polyethylene (HDPE) material with scour flaps made rigid by strips of fiberglass on both the upstream and downstream sides of the barrier. The primary purpose of the scour flap is to prevent oil entrainment, which is likely in regions of high current. The bottom of the barrier is weighted with steel link chains while the top is equipped with flotation to help keep the barrier upright during deployment.

In the Kalamazoo River, RDC tested two different anchoring methods for the inland barrier system, which are dependent on bottom substrate type and water depth. If the river is relatively shallow (less than 10 feet) and has a sandy bottom, the upstream portion of the barrier can be anchored to a post driven into the river bottom with the downstream end tied to a tree or other suitable fixture on the shoreline. In deeper waters or areas of river with harder bottom substrates, the upstream end of the barrier can be anchored to a Jersey barrier with the other end of the barrier tied to the shoreline. RDC was able to learn lessons about deployment and retrieval of the barrier and monitored several aspects of the barrier’s performance including position, motion, sag, scour, and tension using load cells, Global Positioning System (GPS) units, and video cameras.

- Offshore Focus

After conclusion of the inland barrier system field test in Kalamazoo, focus shifted to testing the offshore mitigation system prototype in Lake Huron near Port Huron, Michigan. U.S. Coast Guard Cutter Hollyhock, a 225-foot seagoing buoy tender, was used to deploy the offshore prototype, which was designed particularly for lower current environments (less than 2 knots) and for the purpose of collecting oil in a “U-shaped” configuration rather than deflecting (like the inland barrier system). This prototype is made up of four separate 50-foot sections that were connected for a total length of 200 feet. The barrier itself is made up entirely of HDPE, is approximately 3 feet high, and can be attached to the lake bottom with anchors and stakes with help from divers. Similar to the inland barrier system, it is weighted down with steel link chains, but the top is tied to buoys so that the barrier is able to stay upright as it is being deployed to the lake bottom.

Over the course of three days in May 2018, RDC tested barrier deployment in two different locations of the lake, one in a low current area (less than 1 knot) and another with slightly higher current. RDC collected lessons learned on how the barrier could be best deployed and retrieved. The barrier’s performance was monitored with video cameras and a sonar instrument.

- Today’s Research Yields Tomorrow’s Response Strategy

RDC continues to analyze its findings and will present preliminary results on these first two prototypes in New Orleans this November. RDC is also working to develop a third inland mitigation system prototype for testing at the same location in the Kalamazoo River in April 2019. After the third and final test is completed, RDC will report findings and recommendations about each of the three prototypes. The report will be made available to the public in September 2019.

RDC will end the project by developing a job aid that will describe equipment and tactics useful for detection, monitoring and response options for oil sands products response. This will be available to the public in 2020 and provide the full options for responding to oil sands products spills. With the development of these three prototypes to mitigate the impacts of moving, sunken oil, the Coast Guard will be armed with greater knowledge on methods to respond to these types of oil spills.

The Coast Guard Research and Development Center (RDC), located in New London, Connecticut, is the Coast Guard's facility for performing research, development, test and evaluation in support of the service's major missions. RDC is responsible for evaluating the feasibility and affordability of mission execution solutions and providing operational and risk-management analysis at all stages of the acquisition process. RDC also operates a Maritime Test Facility in Mobile, Alabama.

Alexander Balsley is an environmental engineer and has been a project manager at RDC since 2010. He is primarily involved with RDC’s Oil Spill Response program and is a subject matter expert in this field. Balsley has an M.S. in Environmental Engineering from Worcester Polytechnic Institute, and a B.S. in Civil and Environmental Engineering from Northeastern University. He is a registered Professional Engineer in Massachusetts.

This article first appeared in the September print edition of MarineNews magazine.

-

- Phillips Cartner Elects Principals And Adds New Staff Members Maritime Reporter, Jun 1989 #20

in the U.S. Army. Frank D. M a r c i n k o w s k i, principal engineer in the Services Division in Alexandria, will be responsible for environmental engineering in the engineering services department in Alexandria. Mr. Marcinkowski came to the firm from the U.S. Department of the Interior. Phillips

-

- Clean Venture, Inc. Formed By Spill Contractors To Cover Entire New York Harbor Area Maritime Reporter, Nov 1977 #73

Services of Boston, Mass., will head up Clean Venture as vice president and general manager. The companies forming Clean Venture are Sealand Environmental Engineering, Inc. of Milford, Conn., Industrial Marine Service, Inc. of Norfolk, Va., and Jet Line Services, Inc. of Boston. They will join with Reynolds

-

- MTR100 '13: PCCI, Inc. Marine Technology, Jul 2013 #61

and concrete answers to our client’s most demanding engineering and environmental questions. PCCI, Inc. is a privately owned marine and environmental engineering firm established in 1977. Company headquarters is located in Alexandria, VA, and project offices are in Williamsburg, VA; Ventura, CA; Anchorage

-

- CANADIAN MARITIME INDUSTRIES ASSOCIATION'S 43RD ANNUAL TECHNICAL CONFERENCE Maritime Reporter, Feb 1991 #64

. "Build It or Buy It," by Lt. Comdr. Douglas V.P. Thoreson, Maritime Combat Systems National Defense. "Canadian Naval Initiatives in Environmental Engineering and the Associated Business Opportunities," by Cmdr. R.K. Johnson, Marine and Electrical Engineering, National Defense. "NRC Hull Form

-

- NOx Emissions from Merchant Ships Maritime Reporter, Jun 2003 #68

. Salzburg, Austria: (May 2003). *Corbett, James J., and Koehler, Horst W., "Improving the Accuracy of Ship Emissions Inventories." Marine Environmental Engineering Technical Symposium, MEETS 2003. (August 2003): Arlington, Va. *(in preparation)

-

- Dr. Jennifer Brower, Prometheus Marine Technology, Nov 2013 #18

I completed a National Research Council postdoctoral fellowship at the Naval Research Laboratory in Washington, D.C., and I hold a Ph.D. in Environmental Engineering and Microbiology from Harvard University, and two Bachelor degrees in Engineering from Dartmouth College and the Thayer School of Engineering

-

- Finding Monsters on the Ocean Surface Marine Technology, Nov 2017 #36

maximum wave height greater than 22m was measured, and the extreme wave direction. The Authors Frederic Dias received a PhD in Civil and Environmental Engineering from the University of Wisconsin in 1986. He started his career in the U.S. before coming back to France to join CNRS in 1990. In 2000, he

-

- Expanded Underwater Robotics Ready for Oil Spills Marine Technology, Mar 2018 #24

and available and useful and cheap the system will be. The Author Dr. Javier Gilabert is Professor at the Department of Chemical & Environmental Engineering - Technical University of Cartagena (UPCT) – Spain and PI of the Underwater Robotics Ready for Oil Spill project. (As published in

-

)

March 2024 - Marine Technology Reporter page: 48

)

March 2024 - Marine Technology Reporter page: 48Index page MTR MarApr2024:MTR Layouts 4/4/2024 3:19 PM Page 1 Advertiser Index PageCompany Website Phone# 17 . . . . .Airmar Technology Corporation . . . . . . . . . .www.airmar.com . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .(603) 673-9570 9 . . . . . .Birns, Inc. . . . . . . . . . .

-

)

March 2024 - Marine Technology Reporter page: 46

)

March 2024 - Marine Technology Reporter page: 46NEW TECH OCEANOLOGY INTERNATIONAL 2024 MTR TV’s professional video team was out and about at Oi in London for nearly 20 executive interviews, including [clockwise, starting top left]: Cellula Robotics’ CEO Neil Manning; Rob Dewell, Integration Engineer, Saab UK who put the new eM1-7 electric manipulator

-

)

March 2024 - Marine Technology Reporter page: 42

)

March 2024 - Marine Technology Reporter page: 42NEW TECH OCEANOLOGY INTERNATIONAL 2024 Image courtesy Greg Trauthwein Image courtesy BIRNS MacArtney launches the new ultra-compact ø12.7 mm SubConn Nano connector. Innovative connectivity built on 45 years of ? eld-proven and market-trusted design. Image courtesy MacArtney Birns celebrated its 70th

-

)

March 2024 - Marine Technology Reporter page: 35

)

March 2024 - Marine Technology Reporter page: 35Figure 1 A self-righting vehicle design with buoyancy high and weight low, WHOI’s SeaBED AUV captures the attention of a pair of curious Antarctic penguins as it is deployed from the British research vessel James Clark Ross. Vehicle designers allowed for temperature reduction of battery capacity. Recharge

-

)

March 2024 - Marine Technology Reporter page: 32

)

March 2024 - Marine Technology Reporter page: 32FEATURE SEABED MINING by a sea? oor plume from its pilot collection system test. pact, nodule collection system that utilizes mechanical and The Metals Company recently signed a binding MoU with hydraulic technology. Paci? c Metals Corporation of Japan for a feasibility study on The company’s SMD

-

)

March 2024 - Marine Technology Reporter page: 30

)

March 2024 - Marine Technology Reporter page: 30es the necott. “The focus since then has been on scaling while en- wave, current and vessel motions that in? uence loads in the suring the lightest environmental impact,” says The Metals power umbilical. The LARS can operate in up to 3.5m wave Company CEO Gerard Barron. In-? eld collection system tri- height

-

)

March 2024 - Marine Technology Reporter page: 28

)

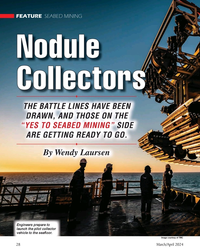

March 2024 - Marine Technology Reporter page: 28FEATURE SEABED MINING Nodule Collectors THE BATTLE LINES HAVE BEEN DRAWN, AND THOSE ON THE “YES TO SEABED MINING” SIDE ARE GETTING READY TO GO. By Wendy Laursen Engineers prepare to launch the pilot collector vehicle to the sea? oor. Image courtesy of TMC 28 March/April 2024 MTR #3 (18-33).

-

)

March 2024 - Marine Technology Reporter page: 26

)

March 2024 - Marine Technology Reporter page: 26FEATURE OCEANOGRAPHIC INSTRUMENTATION & SENSORS Kevin Mackay, TESMaP voyage leader and Center head of the South and West Paci? c Regional Centre of Seabed 2030. Kevin in the seismic lab at Greta Point looking at the Hunga Tonga-Hunga Ha’apai volcano 3D map completed with data from the TESMaP voyage

-

)

March 2024 - Marine Technology Reporter page: 25

)

March 2024 - Marine Technology Reporter page: 25Portable System Requires only UK, Maxlimer mapped the shape of the Wavelet 2KW at 250ms Ping Rate CorrelaO on > 0.96 caldera and measured the environmental conditions of water above it. Sensors on board collected additional data, explained SEA-KIT Operations Director Ash Skett, including bathymetric

-

)

March 2024 - Marine Technology Reporter page: 19

)

March 2024 - Marine Technology Reporter page: 19About the Author vey with the pipe tracker is not required, resulting in signi? - Svenn Magen Wigen is a Cathodic Protection and corrosion control cant cost savings, mainly related to vessel charter. expert having worked across The major advantage of using FiGS on any type of subsea engineering, design

-

)

March 2024 - Marine Technology Reporter page: 17

)

March 2024 - Marine Technology Reporter page: 17. The choice of method depends on factors like the struc- curate calculations of anode currents to assess remaining life, ture’s location, depth, environmental conditions, and the spe- nor determine issues with current drain to or from adjacent ci? c requirements of the maintenance plan. structures

-

)

March 2024 - Marine Technology Reporter page: 15

)

March 2024 - Marine Technology Reporter page: 15sensor options for longer mission periods. About the Author For glider users working in ? sheries and conservation, Shea Quinn is the Product Line Manager the Sentinel can run several high-energy passive and active of the Slocum Glider at Teledyne Webb acoustic sensors, on-board processing, and imaging

-

)

March 2024 - Marine Technology Reporter page: 14

)

March 2024 - Marine Technology Reporter page: 14, which users can choose to activate for a sprint al new use cases for the glider community. With an increased speed of up to 3 knots. need for environmental monitoring, especially to track the “The Sentinel is the world’s fastest glider – its buoyancy impact of offshore construction on the ocean ecosystem

-

)

March 2024 - Marine Technology Reporter page: 13

)

March 2024 - Marine Technology Reporter page: 13signi? cantly grown, alongside the increasing number of use cases for which gliders provide a practical solution. Ocean monitoring – whether for environmental assessments, mammal monitoring, ? sheries, physical oceanography, defense, or dozens of other missions – has driven advance- ments in glider

-

)

March 2024 - Marine Technology Reporter page: 12

)

March 2024 - Marine Technology Reporter page: 12TECH FEATURE TELEDYNE SLOCUM GLIDERS Teledyne Webb Research Engineers deploy the Slocum Sentinel Glider in Cape Cod Bay for testing. Teledyne Webb Research AS THE GLIDER COMMUNITY GROWS, SO DO GLIDERS By Shea Quinn, Slocum Glider Product Line Manager, Teledyne Marine 12 March/April 2024 MTR #3 (1-17).

-

)

March 2024 - Marine Technology Reporter page: 6

)

March 2024 - Marine Technology Reporter page: 6Journal of Diving History and the MTR. Authors & Contributors Konowe Quinn Konowe Celia Konowe is from Reston, Va., and has a bachelor’s degree in environmental studies. She has study abroad experience in France and Ecuador. Currently, she is pursuing her master of environmental studies degree at Dalhousie

-

)

April 2024 - Maritime Reporter and Engineering News page: 48

)

April 2024 - Maritime Reporter and Engineering News page: 48Index page MR Apr2024:MN INDEX PAGE 4/5/2024 1:33 PM Page 1 ANCHORS & CHAINS MILITARY SONAR SYSTEMS tel:+44 (0) 1752 723330, [email protected] , www.siliconsensing.com Anchor Marine & Supply, INC., 6545 Lindbergh Houston, Massa Products Corporation, 280 Lincoln Street, SONAR TRANSDUCERS

-

)

April 2024 - Maritime Reporter and Engineering News page: 46

)

April 2024 - Maritime Reporter and Engineering News page: 46MARKETPLACE Professional www.MaritimeProfessional.com GILBERT ASSOCIATES, INC.GILBERT ASSOCIATES, INC. Naval Architects and Marine Engineers SHIP DESIGN & ENGINEERING SERVICES Join the industry’s #1 Linkedin group )NNOVATION

-

)

April 2024 - Maritime Reporter and Engineering News page: 43

)

April 2024 - Maritime Reporter and Engineering News page: 43“The industry is an ecosystem which includes owners, managers, mariners, shipyards, equipment makers, designers, research institutes and class societies: all of them are crucial,” – Eero Lehtovaara, Head of Regulatory & Public Affairs, ABB Marine & Ports All images courtesy ABB Marine and Ports provi

-

)

April 2024 - Maritime Reporter and Engineering News page: 42

)

April 2024 - Maritime Reporter and Engineering News page: 42OPINION: The Final Word Seeing the Ship as a System Shipping must engage with the decarbonization realities that lie ahead by changing the way it crafts maritime legislation to re? ect its place in the interconnected, interdependent world economy, said Eero Lehtovaara, ABB Marine & Ports. ABB Marine &

-

)

April 2024 - Maritime Reporter and Engineering News page: 41

)

April 2024 - Maritime Reporter and Engineering News page: 41Nautel provides innovative, industry-leading solutions speci? cally designed for use in harsh maritime environments: • GMDSS/NAVTEX/NAVDAT coastal surveillance and transmission systems • Offshore NDB non-directional radio beacon systems for oil platform, support vessel & wind farm applications

-

)

April 2024 - Maritime Reporter and Engineering News page: 40

)

April 2024 - Maritime Reporter and Engineering News page: 40TECH FEATURE SITUATIONAL AWARENESS SITUATIONAL AWARENESS SYSTEM BATTLES COGNITIVE FATIGUE IN WATCHKEEPERS All images courtesy Groke Technologies Today’s evolving maritime security risks pose all-too-familiar threats to international shipping, and as just one of the many causes of fatigue, they add

-

)

April 2024 - Maritime Reporter and Engineering News page: 38

)

April 2024 - Maritime Reporter and Engineering News page: 38Tech Files Latest Products, Systems and Ship Designs Zero-Emission Mooring Service of a Tanker Consulmar achieved a milestone by executing what it calls ing boat Castalia, which operates on full electric propulsion. the world's ? rst zero-emissions mooring service for a tanker. Equipped with two 150 kW

-

)

April 2024 - Maritime Reporter and Engineering News page: 37

)

April 2024 - Maritime Reporter and Engineering News page: 37SIMULATION "A simulated vessel ? ooding can help teams work together to solve the challenge using different systems on the bridge." – Jussi Siltanen, Lead, "The gami? cation of Product Marketing, learning makes it fun." Safety Solutions at NAPA – Captain Pradeep Chawla, Founder, MarinePALS Image