Innovation Driven by Demand - Oil Spill Response

Oil spill equipment manufacturer Elastec brings new and sophisticated tools to a market in need of better, faster, more efficient and environmentally sound tactics. Just what the doctor ordered.

Elastec/American Marine may well be the largest manufacturer of oil spill and environmental equipment in North America, but it is technology and innovation that are quickly propelling the firm to the top of the markets. With six U.S. locations, three foreign offices and a network of global dealers, ISO 9001 certified-Elastec produces a range of products that includes oil spill equipment (skimmers, containment boom, fire boom, dispersant application equipment), incinerators, vacuum systems, portable tanks, pumps and a dozen more entries.

While the firm serves more than one niche segment, Elastec’s design and manufacturing of patented drum and grooved disc oil skimmers, containment and fire booms and the recently acquired BoomVane boom deployment system are perhaps its most exciting and readily visible products. In the beginning, CEO Donnie Wilson and Vice President Jeff Cantrell combined their knowledge and skills of welding, manufacturing, and oil field service with the invention of a drum oil skimmer and established Elastec in 1989. Since then, the firm has been defined by its development of innovative products and systems, some strategic acquisitions and ever-increasing sales in over 145 countries.

The Exxon Valdez oil spill in 1989 was a defining moment in the success of Elastec’s sister company, American Marine, with fire boom (developed in conjunction with 3M), a containment system for the controlled burning of oil spills. Eventually, Elastec and American Marine merged in 2012, but not before the two firms’ combined response team was deployed to the U.S. Gulf for three months to lead the controlled oil burn operation after the Macondo blowout. Wilson and Cantrell, along with a team of employees, corralled more than 300,000 barrels of oil with the patented Hydro-Fire Boom system, a state-of-the-art inflatable fire resistant, water-cooled boom designed to contain and burn surface oil offshore to protect sensitive shoreline habitats.

More recently, Elastec/American Marine were awarded the $1 million first place prize for a remarkable and historic achievement for cleaning up crude oil: Grooved Discs. The competition involved more than 350 entrepreneurs, engineers, and scientists worldwide to develop innovative, rapidly deployable, and highly efficient methods of capturing crude oil from the ocean surface. According to Donnie Wilson, the award – beyond its utility and the good that it can accomplish – was especially rewarding to Elastec shareholders, since he had expended almost $500,000 of their money to make it happen.

The effort to improve and develop rapid response methods and equipment to aid oil spill response efforts led Elastec in 2012 to acquire the marketing and manufacturing rights for BoomVane. Developed and patented by ORC of Sweden, BoomVane simplifies the challenges of deploying containment boom in rivers and tidal waters without the need for boats or anchors. The technology combines the science of sailing with the art of flying a kite, in the water. The result is faster response time and less recovery expense.

Finally, Elastec and Kvichak Marine Industries, a designer and manufacturer of high performance aluminum workboats, formed an alliance in 2013 to better serve customers of MARCO Filterbelt skimmer systems and Kvichak/MARCO Oil Spill Recovery Vessels (OSRVs). The alliance, created to meeting the needs of responders, provides reliable and effective oil spill response vessels and technologies. Today, Elastec both commissions and trains customers in the use of their systems and also supervises burn control operations.

Three for the Money

On the water today, Elastec’s three premier products involve the newly acquired BoomVane technology, the newly invented Grooved Disc Oil Skimmer and its patented line of oil spill, fire retardant booms.

In Situ Burning: Elastec is active in developing Arctic Specific response technology. That said, Arctic response methods change depending on the season. So, what do you build for? What Elastec found was that burning in ice is extremely effective. In fact, it works under most, if not all conditions. The downside of burning is the particulate matter that eventually dissipates; hence this method of response is usually seen offshore. Wilson said “typically, you need to be three to four miles offshore. It can be done in inland waters, too, but the permitting process is more in-depth.”

In terms of oil spill response, fire booms are a real specialty item and only three firms sell them today. For its part, Elastec produces two types: a seawater cooled system and one other; a ceramic model. The former works well as sea water is pumped through the boom to protect the fire retardant fabric that covers the boom. Ceramic booms, while simpler to use, are not as robust. Not as much training is needed pre-deployment and the booms are less expensive. As one might expect in this type of business, however, they have about half the life expectancy of their water-cooled cousins.

Elastec personnel and equipment more than proved their mettle during the recent Macondo Gulf oil spill. Donnie Wilson managed the controlled burning of oil for BP America with a team of employees and response contractors. The company’s fire boom systems were responsible for containing and disposing of more oil than any other system during the burn operation. In charge of all controlled burns, Wilson initially had three teams on site but that grew to 14 by the end of the crisis. In total, Elastec lit 411 fires and burned 300,000 barrels during continuous deployment of more than 80 days. Wilson’s crew used floating booms to corral surface oil and burn it and the effort required 80 total systems with 500 ft. booms; and 48,000 ft. of boom in total.

Wilson explains the process of controlled burns by saying, “Oil will not burn unless it is at least 1/8- ¼” in. thick. About one inch of oil burns every 10 minutes. We light the spills with hand-held igniters consisting of jelled fuel.”

When it was all said and done, however, watching all that petroleum go up in smoke inspired Wilson and his firm to develop a high-volume drum skimmer that could collect more oil, rather than wasting it.

Eventually, Elastec created a skimmer that removes oil from the water with 90% efficiency, a much higher rate than any other skimmer on the market. That’s not surprising, since he and his team invented oil drum skimmers, way back in 1989. In fact, the new skimmer collected an unheard of 4,670 gallons a minute. Elastec/American Marine hopes to have units ready to deploy by the end of this year.

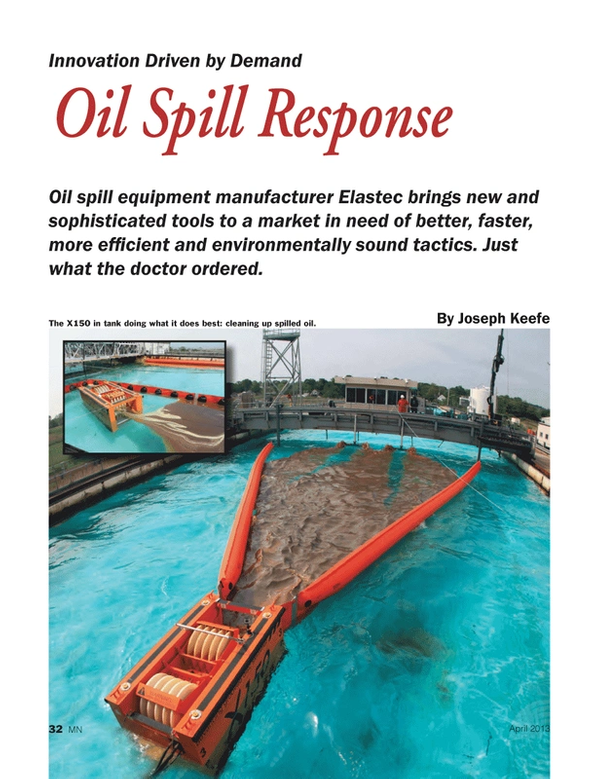

Grooved Disc Skimmer: The Grooved Oil Disc Skimmer, so far only recently commercialized, is in the process of being developed into full system which will include a self-contained launching system and the BoomVane. In actual practice, the skimmer is towed at as much as two to three knots, much faster than the 0.75 knots common for lesser skimmers. According to Donnie Wilson, the advantages are many. “You can stay clutched in and still maintain steerage and not all vessels are set up or equipped for launch and retrieval,” he said.

Used in conjunction with the Grooved disc Skimmer, the Swedish designed BoomVane, built specifically to deal with oil in inland waters, deflects oil to shore where skimmers can efficiently pick it up. The BoomVane “holds the boom open” as it is deployed. The entire system could be ready by the end of this year. As a one-two punch, the two constitute perhaps the most powerful (combined) innovation in oil spill response in more than 50 years. The X-150, with its groove disc system has a capacity of 660 gallons per hour. The Boom vane system corrals the oil, with just one captain in charge of operation whereas other systems or methods need two boats. This represents, in and of itself, significant cost savings. The boom vane itself rudders the boom away from the shore.

BoomVane: This powerful device allows for rapid boom deployment in a wide range of environments such as rivers, canals and estuaries without the use of boats, anchors or fixed installations. The patented BoomVane can also be partnered with a boat to operate a single vessel sweep system without the need for an outrigger arm. A cascade of vertical vanes under the wave-rider float allow the BoomVane to advance against the water current at speeds of 0.5 to >5 knots. The system can be operated in waters with heavy traffic and debris. The lightweight design and control rudder allows for easy retrieval and relaunching. BoomVane also folds up for compact storage and transport in boats and utility vehicles. It can be reassembled without tools in minutes. Specifically designed for shore based river operations in shallow waters, it can also deployed off a towing vessel to reach near the shoreline with booms and absorbents, where it is too shallow for the vessel to go.

The largest BoomVane – the Ocean BoomVane – is designed for coastal and offshore single vessel operations with medium to large oil booms and advancing containment and recovery systems. All BoomVane units are built for maximum performance in water speeds ranging from one to five knots and are self-balancing, so no adjustments or trimming is required.

More than 400 BoomVanes have been supplied around the world, helping responders to quickly and efficiently contain and/or deflect oil to protect shorelines and sensitive aquatic habitats. No doubt, and in conjunction with Elastec’s new X-150 skimmer, hundreds more will be sold in the near term. Ultimately, the environment will be the real benefactor.

Looking Back: Working Forward

A common complaint in the wake of the EXXON VALDEZ disaster was that oil spill response research – when it wasn’t being thwarted by regulatory constraints here at home – was too oil tanker centric and not focused enough on the emerging threats of Arctic melting and the burgeoning oil & gas, deepwater markets. There was (perhaps) merit to that argument, but not when it came to the efforts of Elastec and its innovative efforts. The best may be yet to come.

With three primary technologies driving the oil spill response markets of today – all of which seem to emanate from Elastec itself – innovation may be the least of our problems. The question of what comes next is likely being drawn up as you read this article, in the workshops of Elastec. Count on it.

(As published in the April 2013 edition of Marine News - www.marinelink.com)

Read Innovation Driven by Demand - Oil Spill Response in Pdf, Flash or Html5 edition of April 2013 Marine News

Other stories from April 2013 issue

Content

- Editor's Note page: 6

- By the Numbers: Oil Spill Response page: 8

- Tampa Yacht Manufacturing’s TEMPEST 50-FAC page: 10

- Insights: Chris Charman Chief Executive, International Marine Contractors Association page: 12

- Safe Operations, Proven Results page: 18

- Key Salvage Issues for 2013 – and Beyond… page: 20

- Offshore Energy page: 22

- Medicare Set Asides – and You page: 24

- The Macondo Spill Trial page: 26

- Innovation Driven by Demand - Oil Spill Response page: 32

- A Tailored Approach to VSAT for Workboats page: 38

- Caterpillar’s Marine Center of Excellence page: 44

- Using Mediation: Eliminate Risk and Conserve Litigation Expenses page: 50

- JK Fabrication’s Emergency Towing Reel page: 54